Chemical corrosion method of manganese doped gallium antimonide monocrystalline

A chemical corrosion, gallium antimonide technology, applied in the field of semiconductor material physics and chemistry, can solve the problem of no chemical corrosion and achieve good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

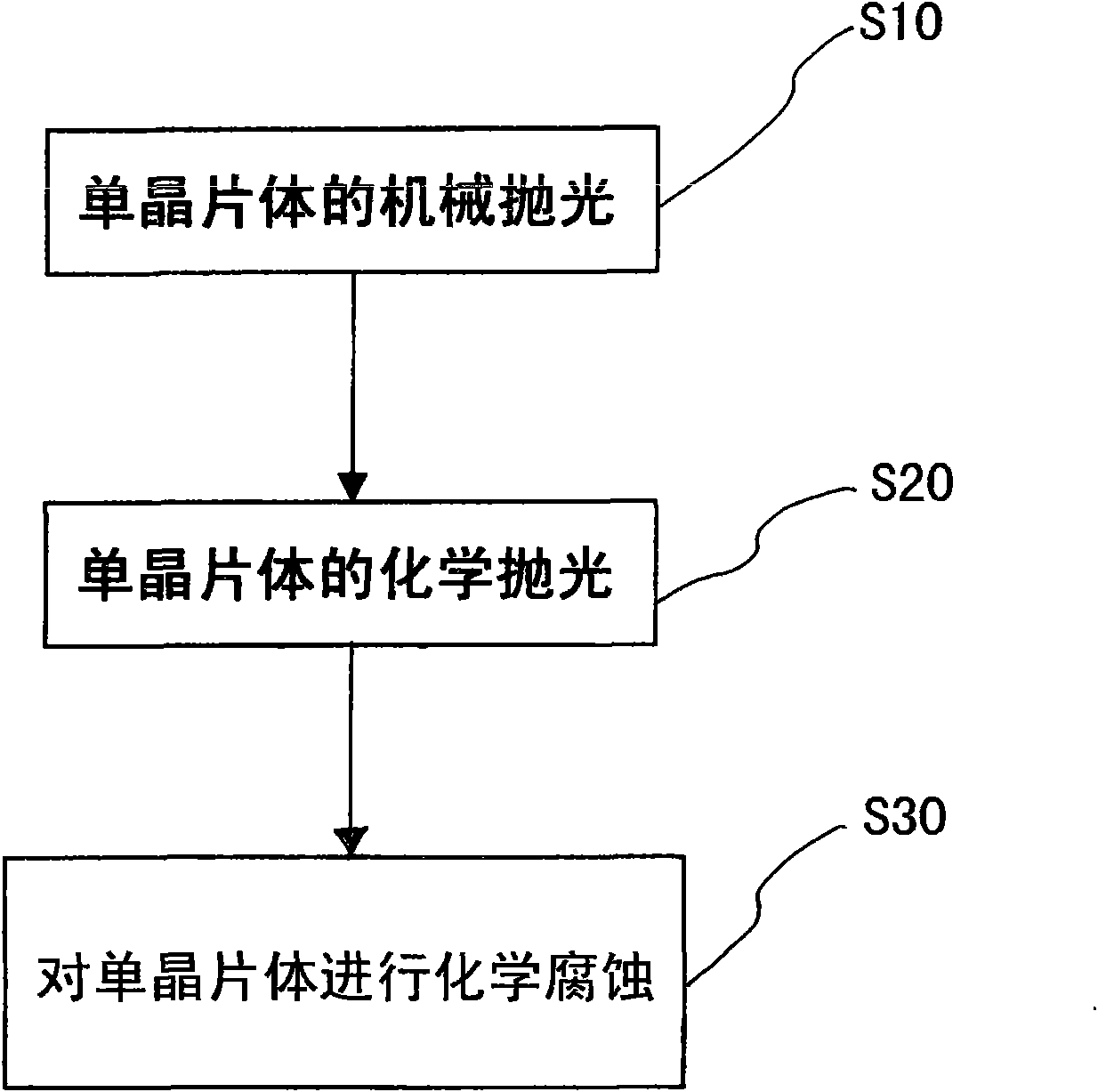

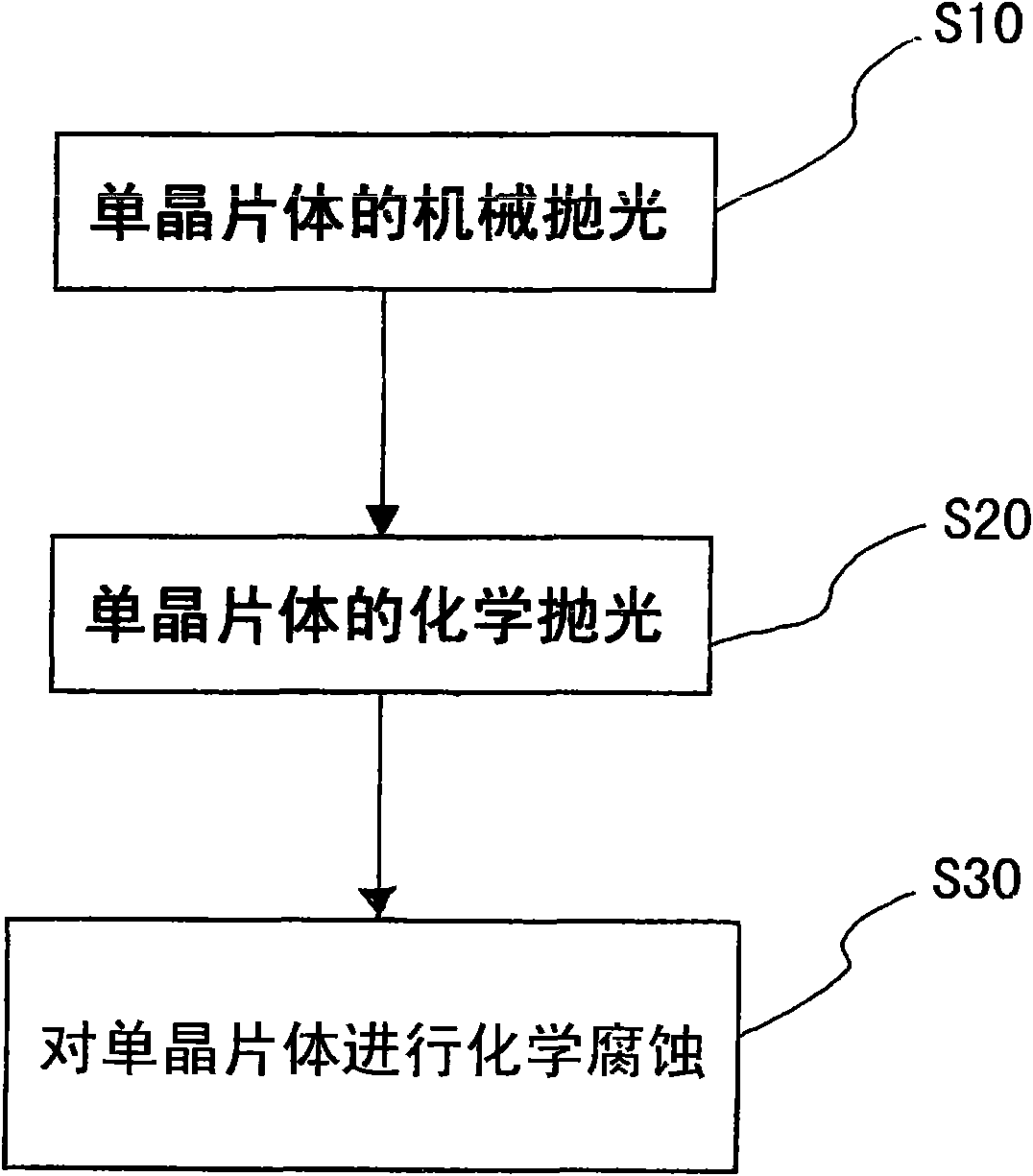

[0018] see figure 1 Shown, the chemical etching method of a kind of manganese-doped gallium antimonide single crystal of the present invention, comprises the following steps:

[0019] Step 1 (S10): Take a single wafer body, and use polishing powder to mechanically polish the single wafer body, wherein the material of the single wafer body is manganese-doped gallium antimonide, wherein the mechanical polishing is manual polishing , the polishing powder used is: Al 2 o 3 , to remove the cut marks on the surface of the single wafer.

[0020] The details that need to be paid attention to during the mechanical polishing process of single crystal include the following aspects. Before polishing, add water to the polishing powder, filter it with gauze, and use the filtered powder for polishing. This is mainly to filter out the large particles in the polishing powder, and try to avoid introducing new wear marks during mechanical polishing. When grinding, proceed in the order of ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com