GaN-based flip-chip light-emitting diode with double reflecting layers and preparation method thereof

A light-emitting diode, gallium nitride-based technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced reflectivity of metal reflective layers, low surface resistance, and high production costs of high-brightness LEDs, and achieves improved luminous efficiency, The effect of excellent reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] The preparation process of gallium nitride-based flip-chip light-emitting diodes with a double reflection layer of a distributed Bragg reflection layer and a metal reflection layer, the steps are as follows:

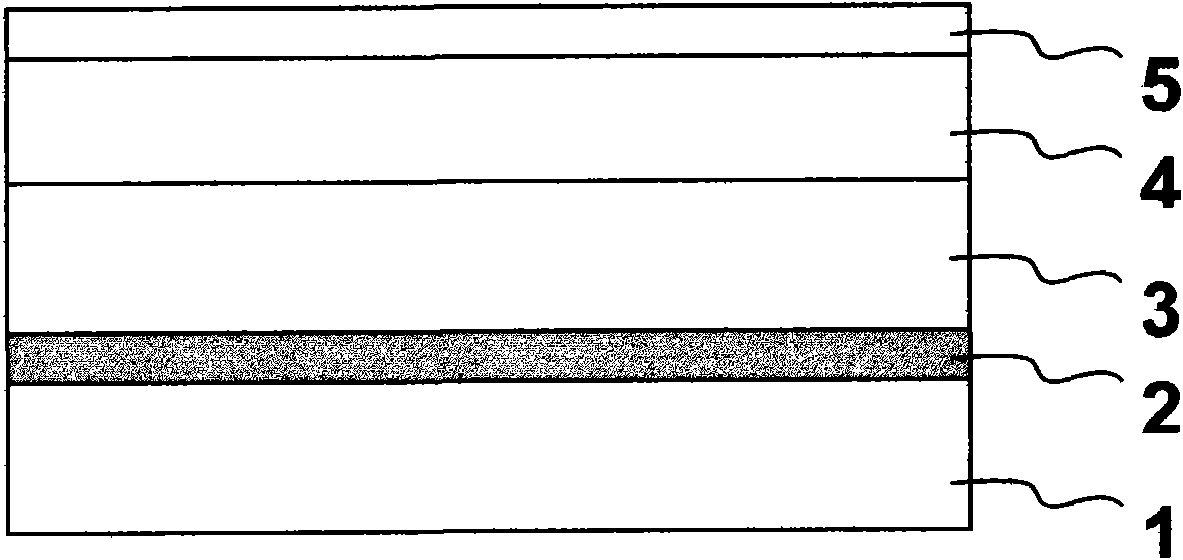

[0033] Such as figure 1 As shown, a GaN buffer layer 2, an N-GaN layer 3, a multi-quantum well layer 4 and a P-GaN layer 5 are sequentially grown on a sapphire substrate 1;

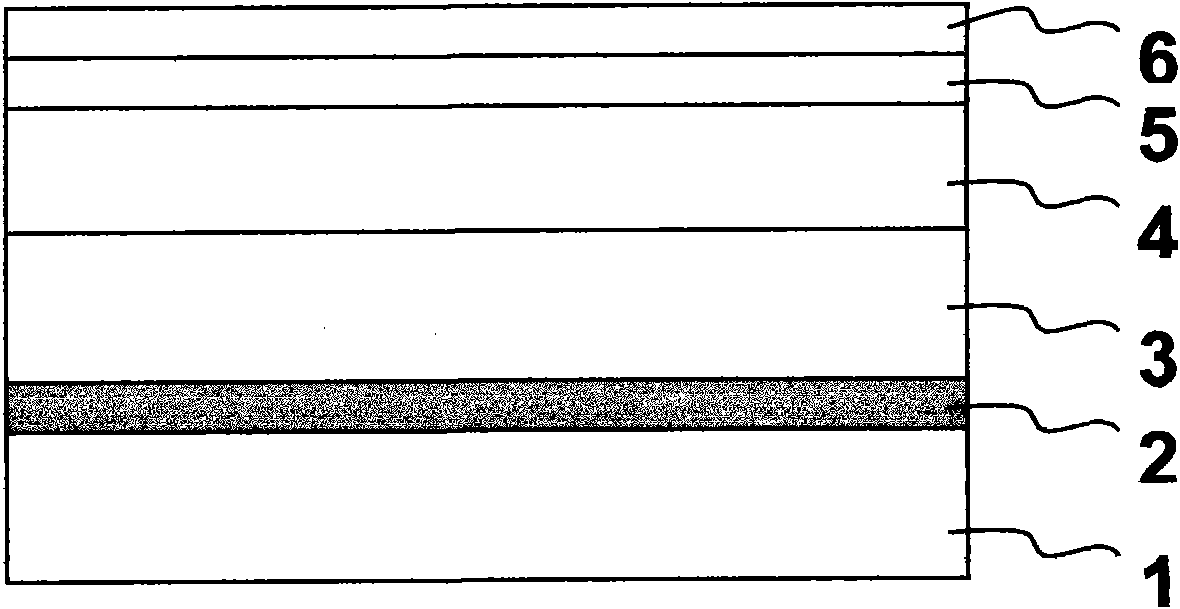

[0034] Such as figure 2 As shown, an ITO transparent conductive layer 6 is formed on the P-GaN layer 5;

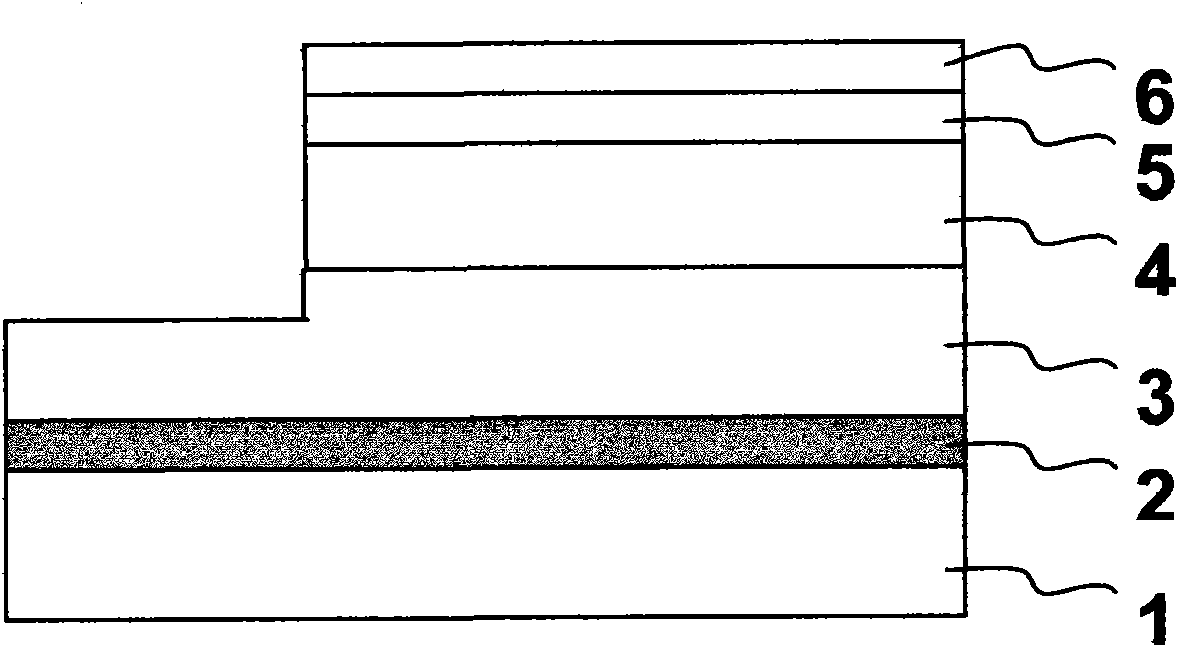

[0035] Such as image 3 As shown, through a photomask and etching, the part of the mesa where the ITO transparent conductive layer 6 is located is etched to expose the N-GaN layer 3;

[0036] Such as Figure 4 As shown, the N-electrode ohmic contact metal layer 7 is formed on the N-GaN layer 3, and the N-electrode ohmic contact metal layer 7 is selected from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com