EMI filter module based on magnetic integration

A filter and magnetic integration technology, which is applied in the direction of inductors with magnetic cores, impedance networks, electrical components, etc., can solve the problem that the filtering performance is greatly affected by temperature and frequency changes, so as to reduce the requirements for dielectric materials and improve Performance stability, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

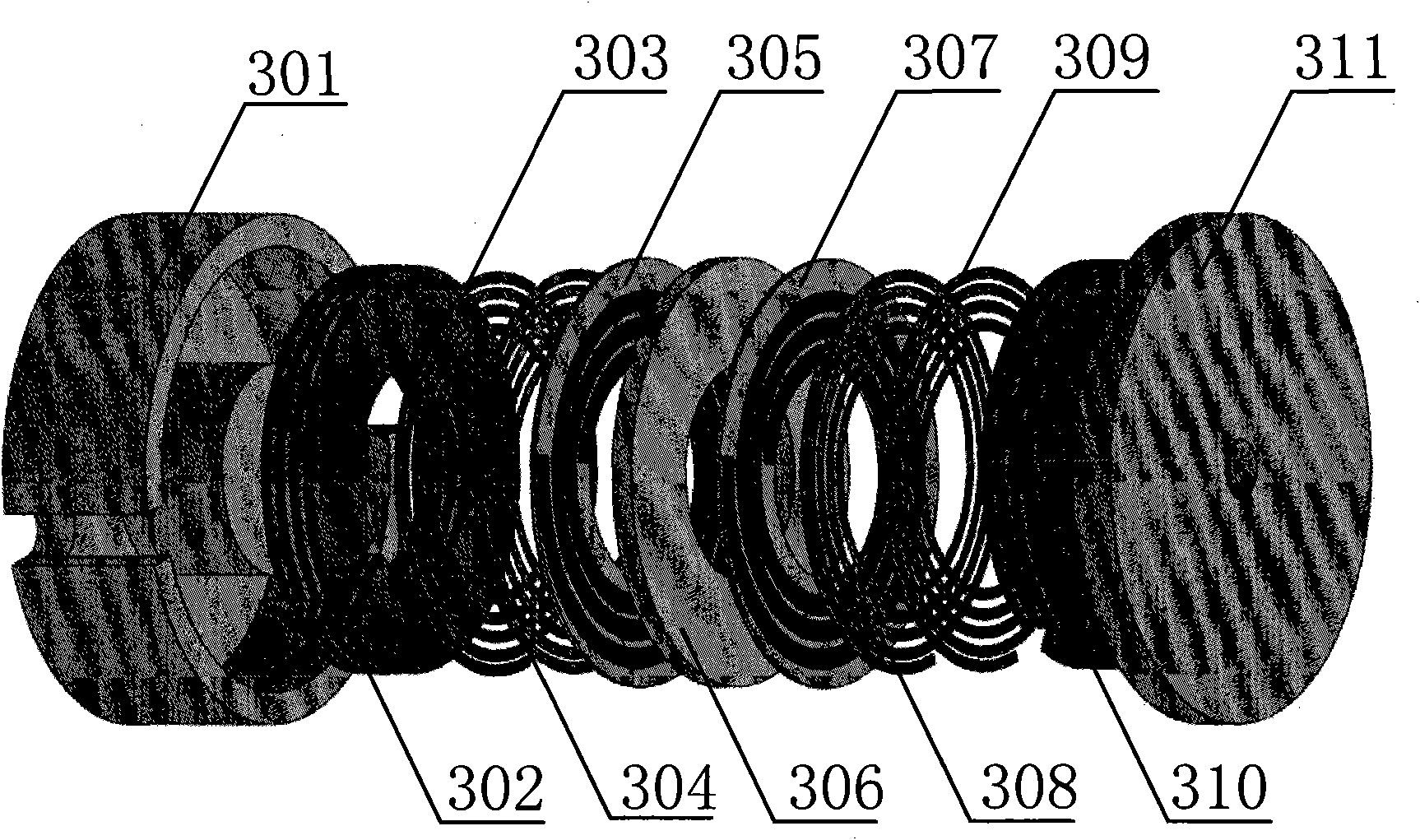

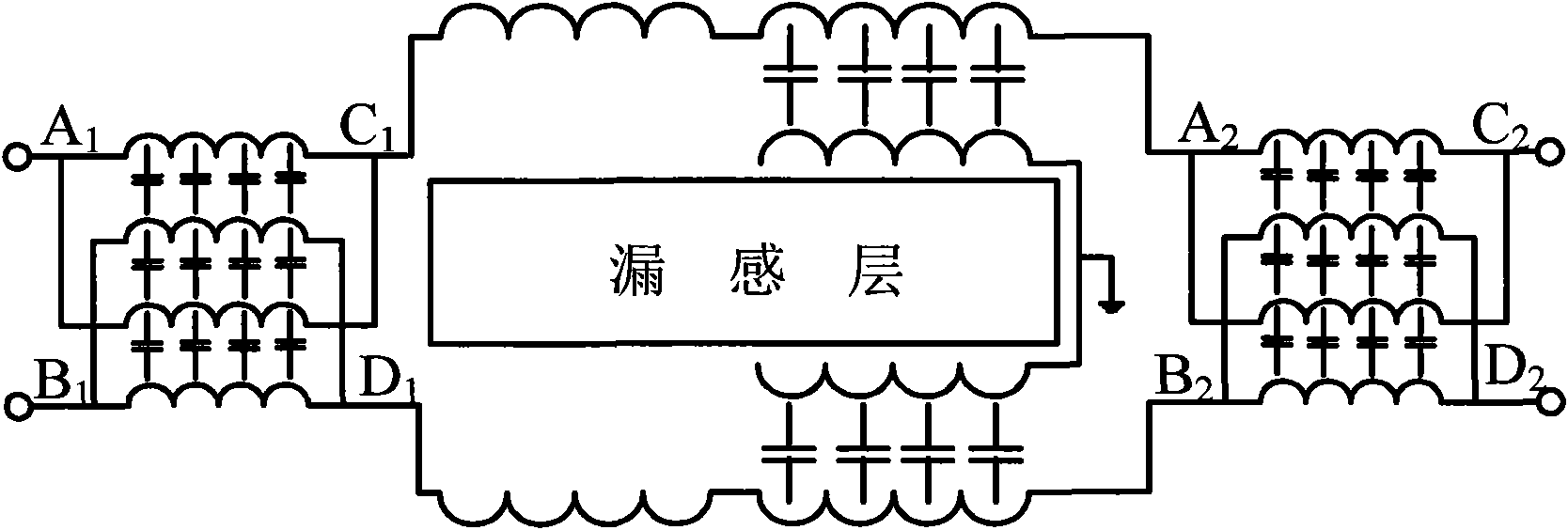

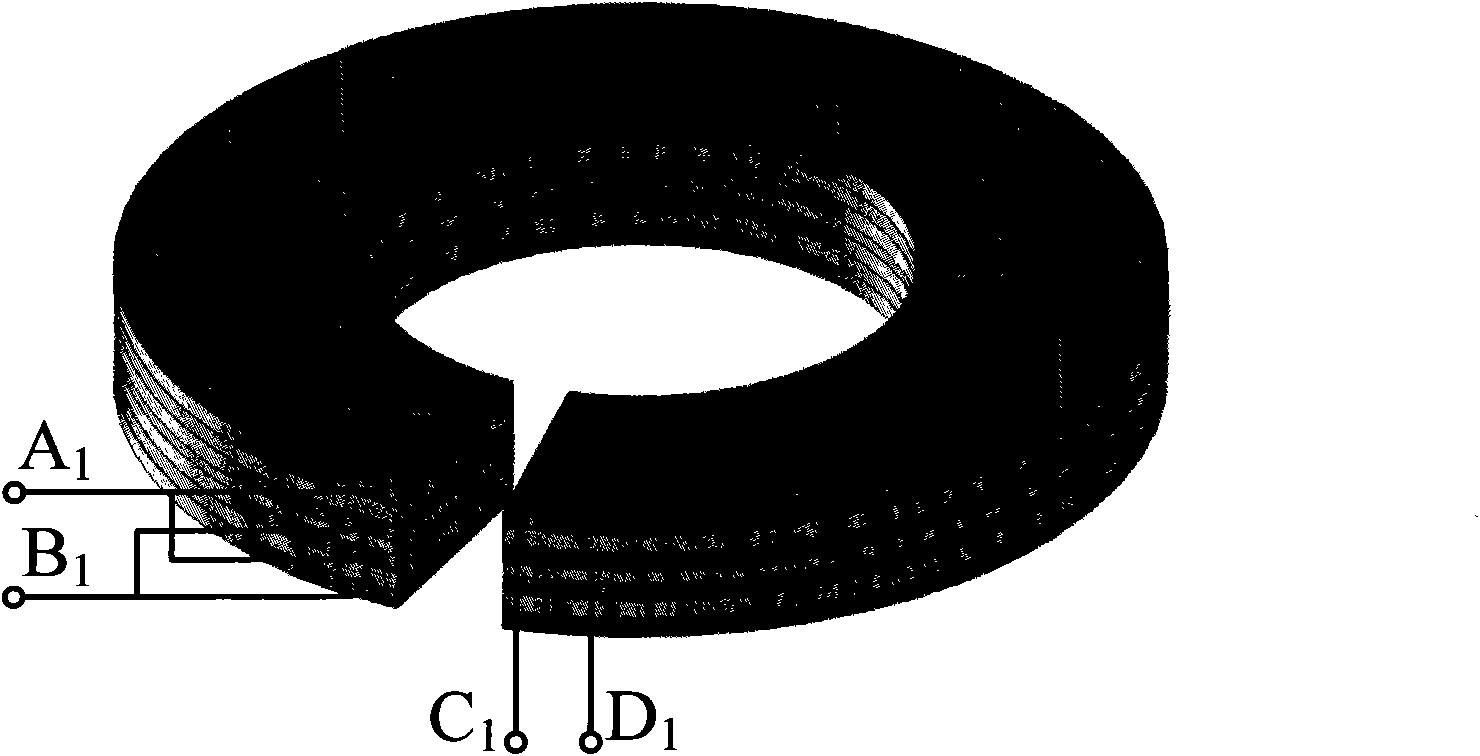

[0018] An EMI filter module based on magnetic integration, as attached figure 1 As shown, it includes a magnetic core, a common-mode inductance layer, a common-mode integrated inductance structure, a leakage inductance layer and a differential-mode capacitor, wherein the magnetic core includes a pot core 301 and a flat core 311, and the differential-mode capacitor includes Differential mode capacitor I 302 and differential mode capacitor II 310, common mode inductor layer includes common mode inductor layer I 303, common mode inductor layer II 304, common mode inductor layer III 308 and common mode inductor layer IV 309, common mode integrated inductor structure includes common mode integrated inductor Capacitive structure I305 and common-mode integrated inductive structure II307; common-mode inductive layer I303, common-mode inductive layer II304 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com