Anchovy-acete chinensis on-board mechanical processing process and on-board arrangement

A processing technology, the technology of hairy shrimp, is applied to the arrangement of related equipment on the ship, the process of mechanized processing of hairy shrimp on board, and the field of anchovies, which can solve the problem of large damage to the external body of fish and shrimp, inability to use, and processing volume is not too large and other problems, to achieve the effect of short transmission process, great economic and social benefits, and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

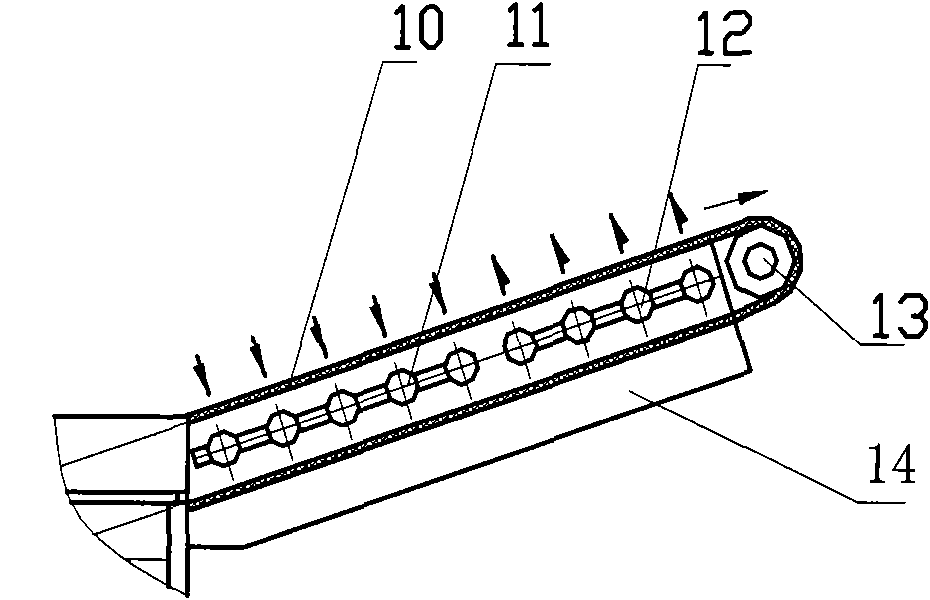

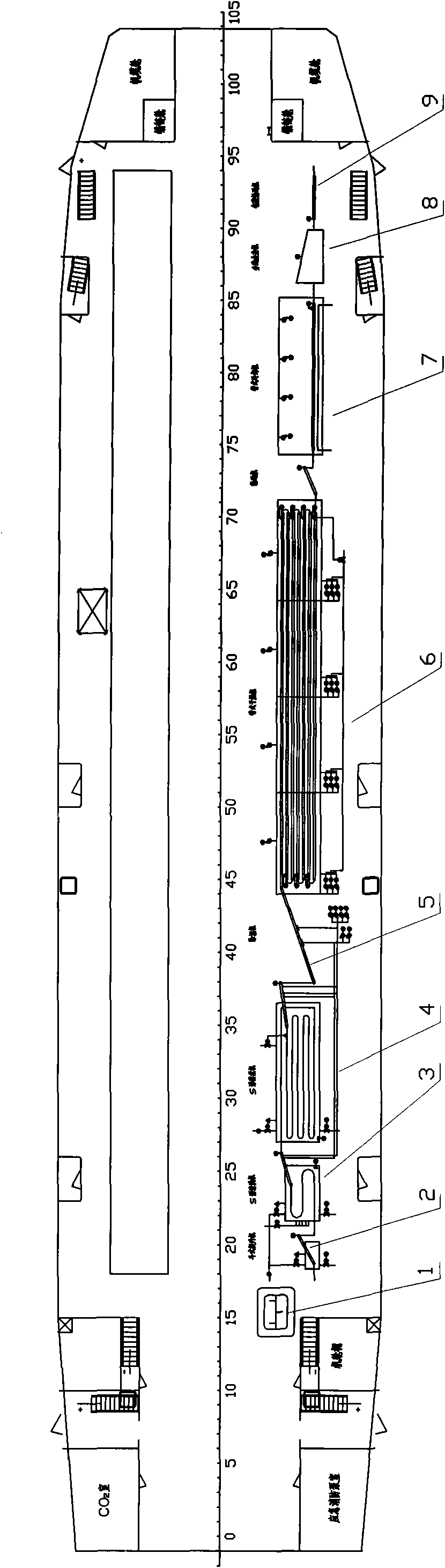

[0052] The present invention will be further described below with reference to the accompanying drawings.

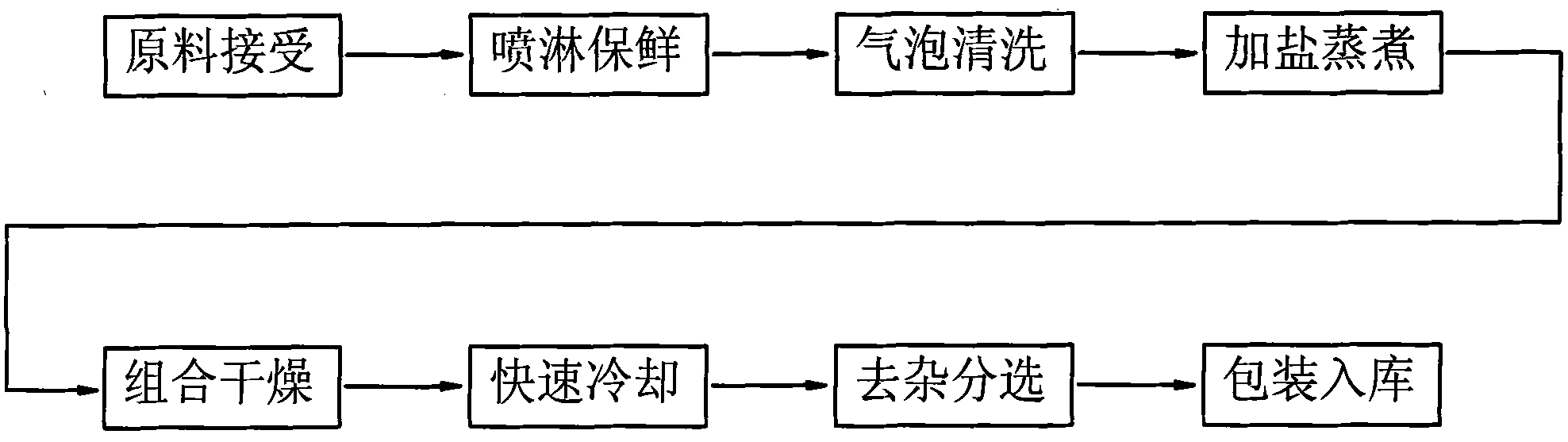

[0053] A ship-board mechanized processing technology for anchovy and hairy shrimp, characterized in that the process includes the following steps: raw material receiving→spraying to keep fresh→bubble cleaning→salting and cooking→combined drying→rapid cooling→impurity removal and sorting→packing library, the specific requirements are:

[0054] The raw material receiving process: the fresh anchovy and hairy shrimp are transported from the paired fishing ship to the processing ship by the transport ship, and the raw material is dipped in cooled seawater on the transport ship to cool down, and the temperature of the raw material is kept below 10°C;

[0055] The spraying fresh-keeping process: the received raw materials are kept fresh in the fresh-keeping pool, sprayed with cooled seawater, and the temperature of the cooled seawater is 0--2°C;

[0056] The bubble cleaning pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com