Plate type plasma reactor for hydrogen production through ammonia decomposition

A plasma and reactor technology, applied in the field of plasma chemistry and hydrogen energy, can solve the problems of electronic equipment interference, severe discharge, light column wandering, etc., and achieve the effects of less harmful radiation, increased discharge current density, and stable discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

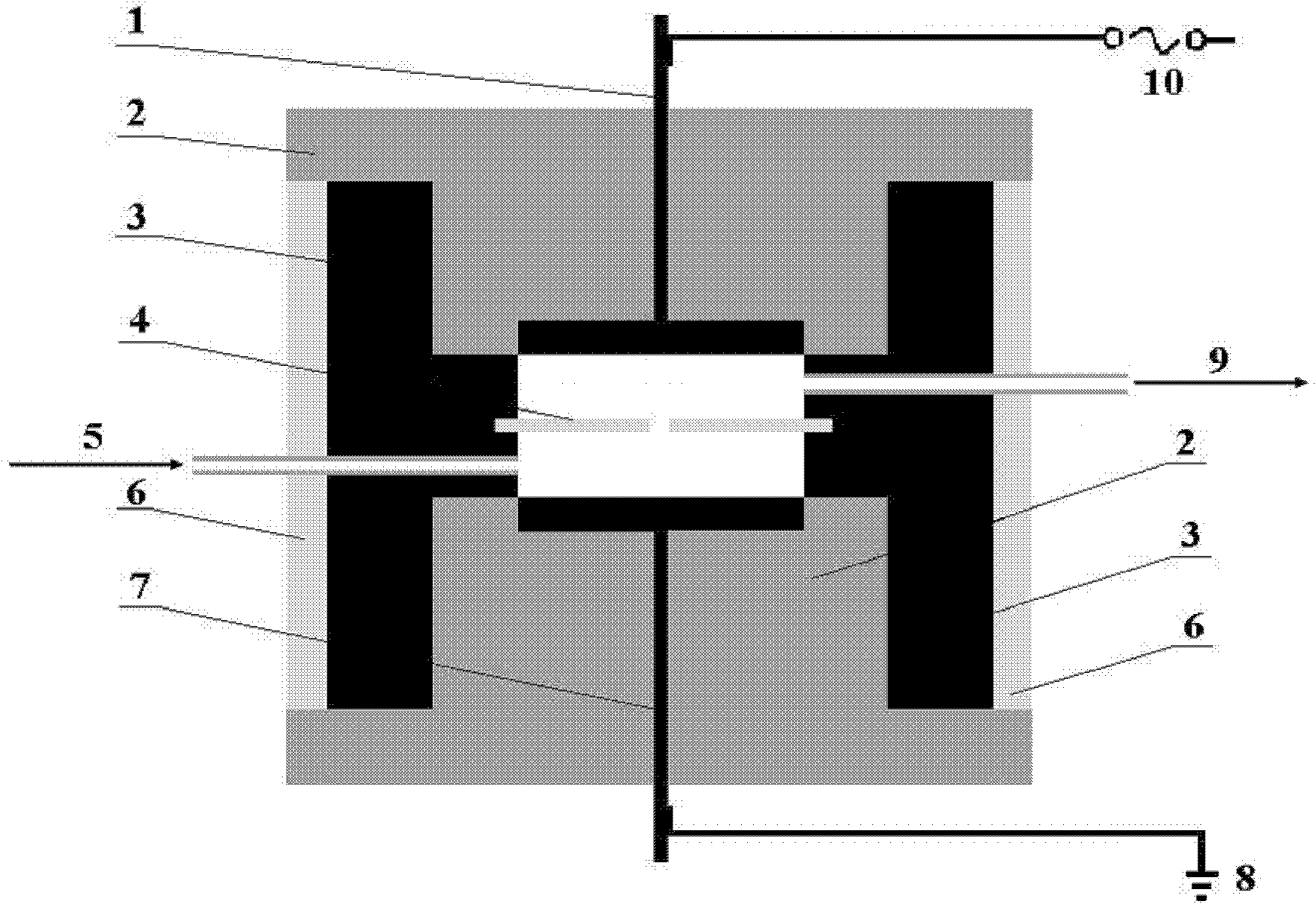

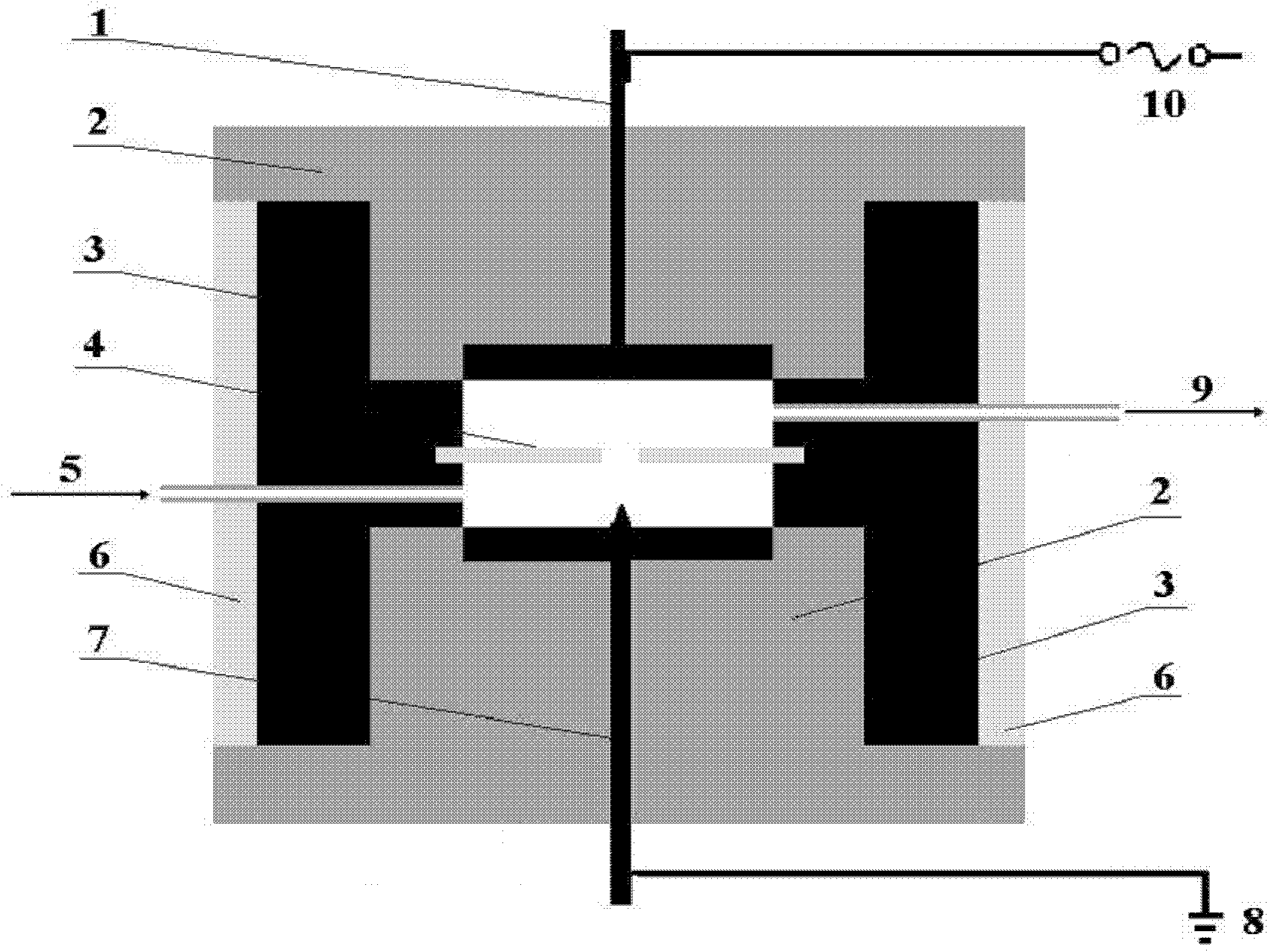

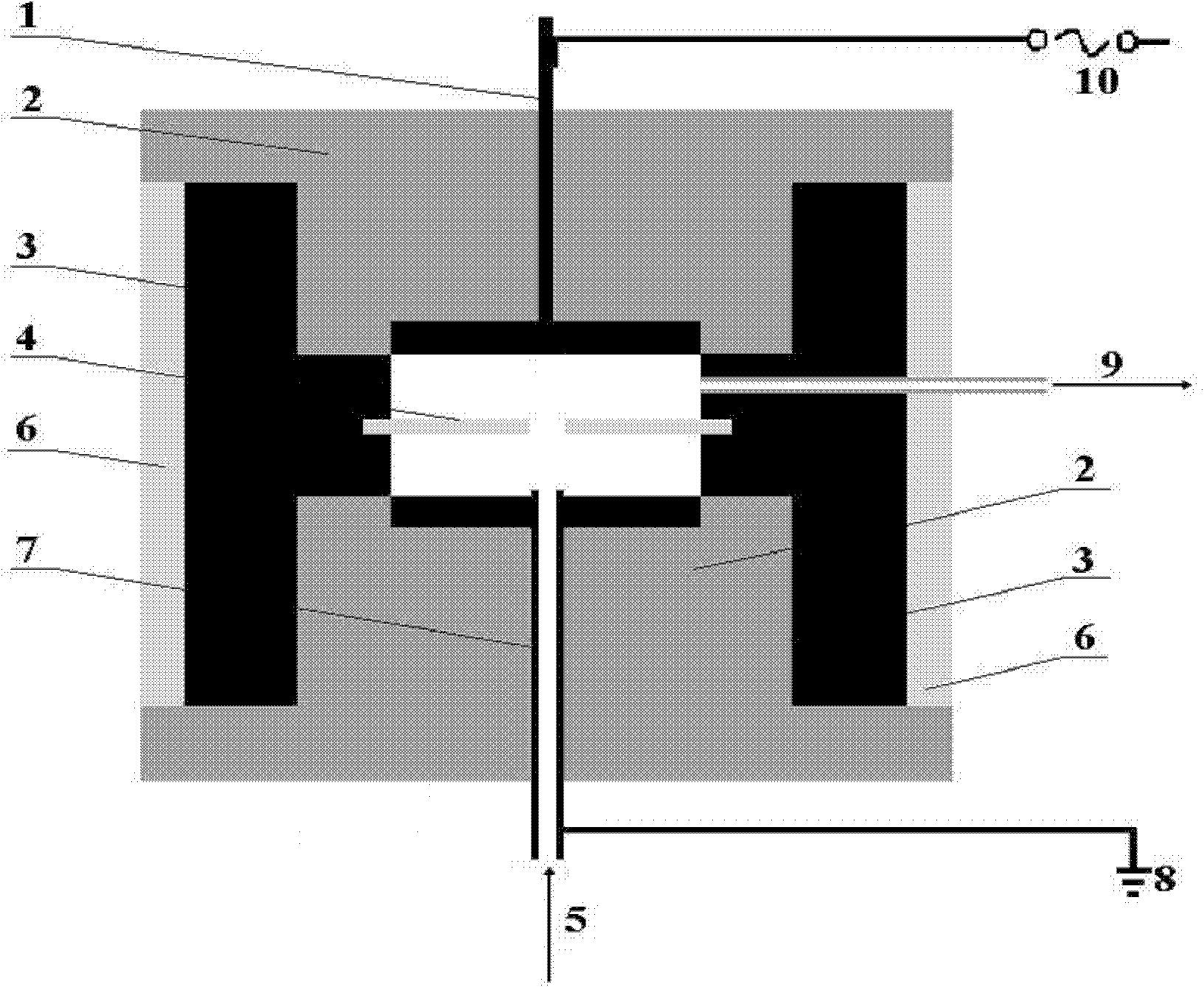

Embodiment 1

[0069] Anhydrous liquid ammonia is drawn from the storage tank through the pressure reducing valve, and the flow rate of the ammonia gas reaches 40 milliliters / minute through the control of the flow meter and the regulating valve, and the air inlet 5 ( figure 1) into the plate plasma discharge reactor. The metal plate discharge electrodes 1 and 7 of the reactor are made of ordinary stainless steel, with a diameter of 50 mm and a thickness of 3 mm. The insulating seal 2 between it and the reactor shell is made of polytetrafluoroethylene material, and the distance between the two metal electrodes is 4 mm. An insulating barrier dielectric plate with a surface-center opening of 3 mm is placed in parallel between the two metal electrodes. The insulating medium is made of quartz material with a thickness of 1 mm, and the distance from the high-voltage electrode plate and the grounding plate is 1.5 mm. On the reactor wall between the grounding electrode and the barrier medium plate, ...

Embodiment 2

[0071] Example 1 was repeated, but the discharge parameters were set as follows: the initial voltage of the transformer was 70 volts, and the discharge frequency was 13 kHz. Then the power of the high-voltage power supply reaches 21 watts, the actual discharge voltage is 4.9 kV, the temperature of the reactor is stabilized at 139° C. after the reaction is stable, and the ammonia decomposition conversion rate reaches 47%.

Embodiment 3

[0073] Example 1 was repeated, but the discharge parameters were set as follows: the initial voltage of the transformer was 80 volts, and the discharge frequency was 13 kHz. Then the power of the high-voltage power supply reaches 24 watts, the actual discharge voltage is 5.4 kV, the temperature of the reactor is stabilized at 148°C after the reaction is stable, and the ammonia decomposition conversion rate reaches 52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com