Method for preparing granular active carbon for gasoline vapor recovery by using oil tea shells

A technology of granular activated carbon and Camellia oleifera husk, which is applied in the field of granular activated carbon for the recovery of gasoline vapor from Camellia oleifera husk, which can solve the problems of air pollution, large gasoline consumption, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

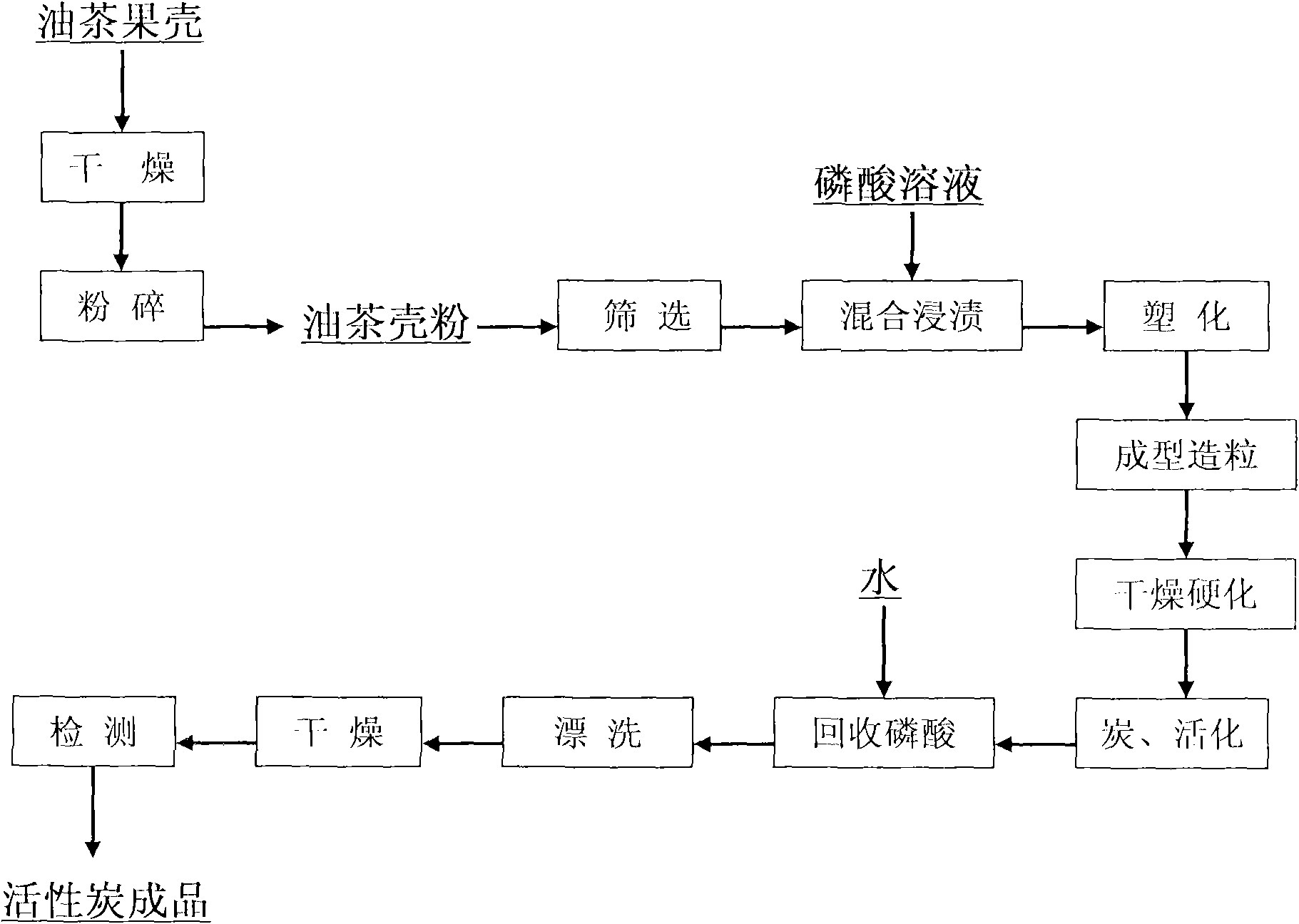

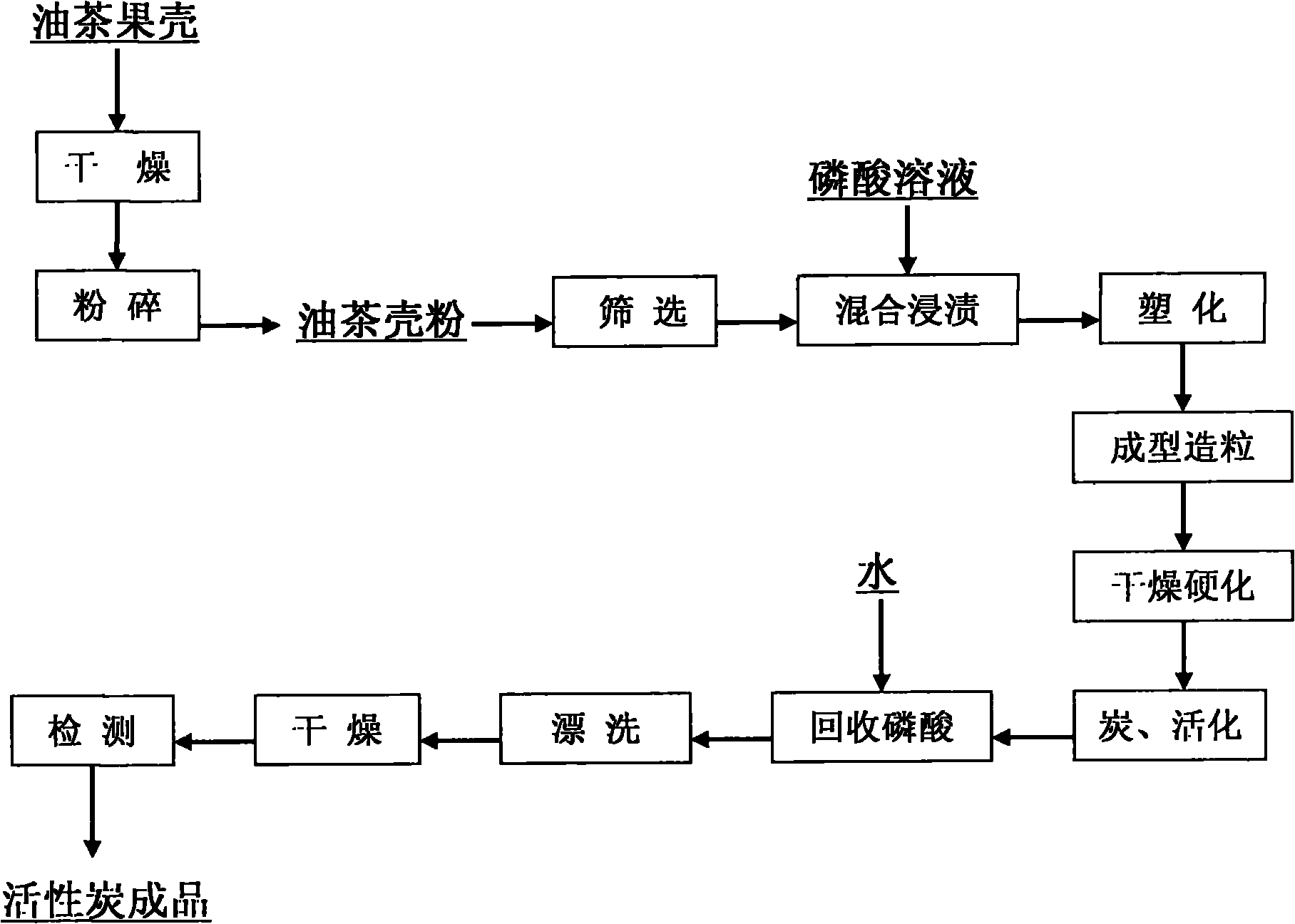

Method used

Image

Examples

example 1

[0009] Dry the camellia oleifera shell at 100°C and crush it to 30-60 meshes, stir and mix the camellia oleifera shell powder and 85% phosphoric acid solution in a weight ratio of 1:2 and let it stand for 24 hours, then place the mixture in Plasticize in a constant temperature oven at 90°C for 1 hour, put the plasticized material into a screw extruder to make columnar particles with a diameter of 2mm and a length of 5-10mm, and dry and harden in an oven at 120°C for 1 hour. Finally put it into a rotary activation furnace and activate it at 450°C for 1.5 hours. After cooling, the activated material is rinsed with water until the pH value is 5-7. Put the rinsed charcoal into a constant temperature oven and dry it at 100-105°C for 2 hours. , just make the active carbon product that oil camellia shell gasoline vapor recovers, and its butane working capacity is 16.5g / 100ml, and wear-resisting strength is 90%.

example 2

[0011] Dry the camellia oleifera shell at 100°C and crush it to 30-60 meshes, stir and mix the camellia oleifera shell powder and 75% phosphoric acid solution in a weight ratio of 1:2 and let it stand for 24 hours, then place the mixture in Plasticize in a constant temperature oven at 100°C for 1 hour, put the plasticized material into a screw extrusion molding machine to make columnar particles with a diameter of 3mm and a length of 5-10mm, and dry and harden in an oven at 110°C for 1 hour. Finally, put it into a rotary activation furnace and activate it at 500°C for 2 hours. After cooling, the activated material is rinsed with water until the pH value is 5-7. Put the rinsed charcoal into a constant temperature oven and dry it at 100-105°C for 2 hours. , the activated carbon product for recovery of camellia oleifera shell gasoline vapor is obtained, the butane working capacity is 15.5g / 100ml, and the wear resistance is 88%.

example 3

[0013] Dry the camellia oleifera shell at 100°C and crush it to 30-60 meshes, stir and mix the camellia oleifera shell powder and 65% phosphoric acid solution in a weight ratio of 1:2.5 and let it stand for 24 hours, then place the mixture in Plasticize in a constant temperature oven at 100°C for 1.5 hours, put the plasticized material into a screw extrusion molding machine to make columnar particles with a diameter of 2mm and a length of 5-10mm, and dry and harden in an oven at 110°C for 1 hour. Finally put it into a rotary activation furnace and activate it at 550°C for 2.5 hours. After cooling, the activated material is rinsed with water until the pH value is 5-7. Put the rinsed charcoal into a constant temperature oven and dry it at 100-105°C for 2 hours. , the activated carbon product for recovery of camellia oleifera shell gasoline vapor is obtained, the butane working capacity is 14.8g / 100ml, and the wear resistance is 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com