La2O3-doped lead zinc niobate-lead zirconate titanate piezoelectric ceramic

A piezoelectric ceramic, lead zirconate titanate technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of dielectric loss, large dielectric loss, etc., and achieve dielectric loss The effect of small, high piezoelectric coefficient and excellent piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

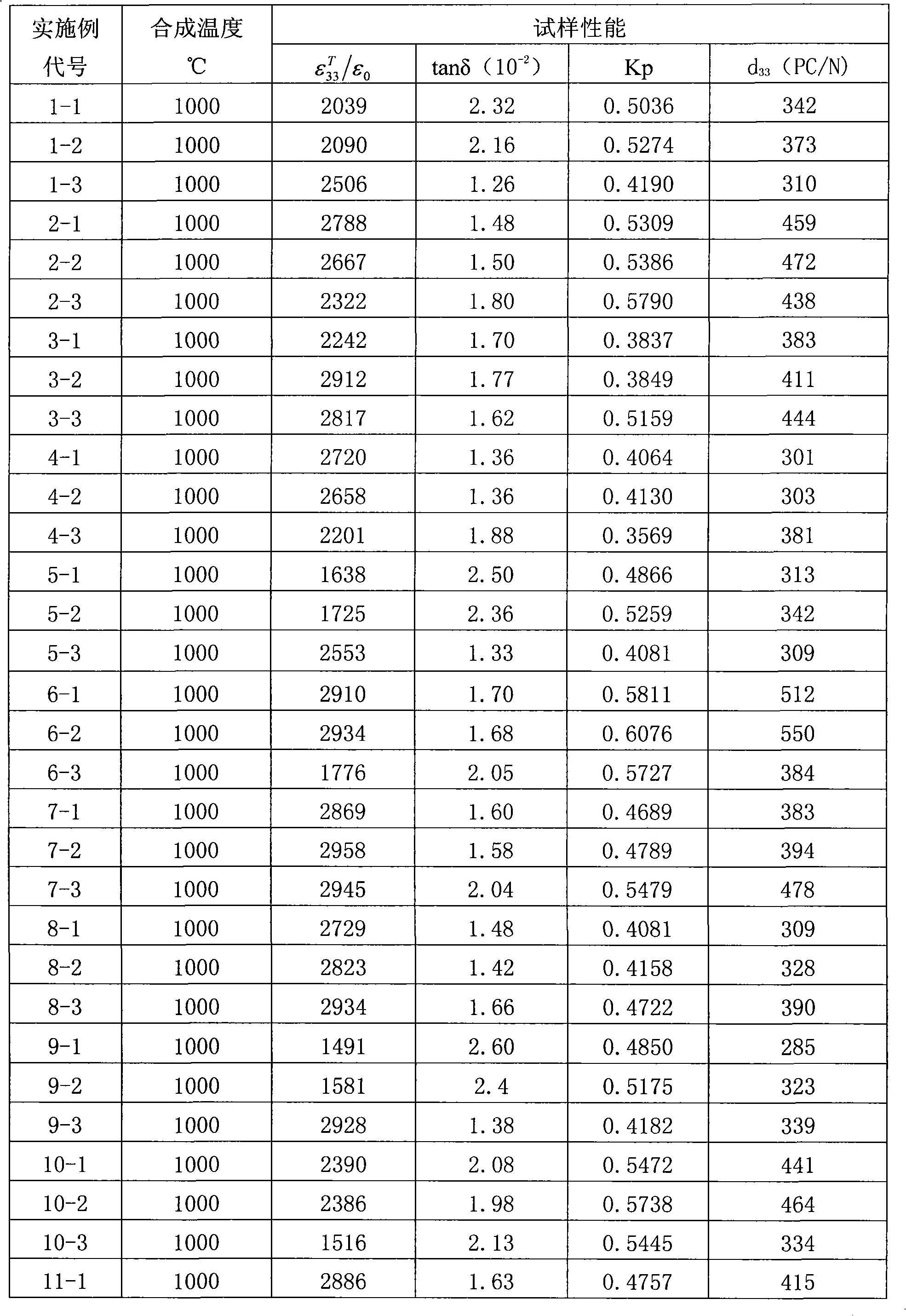

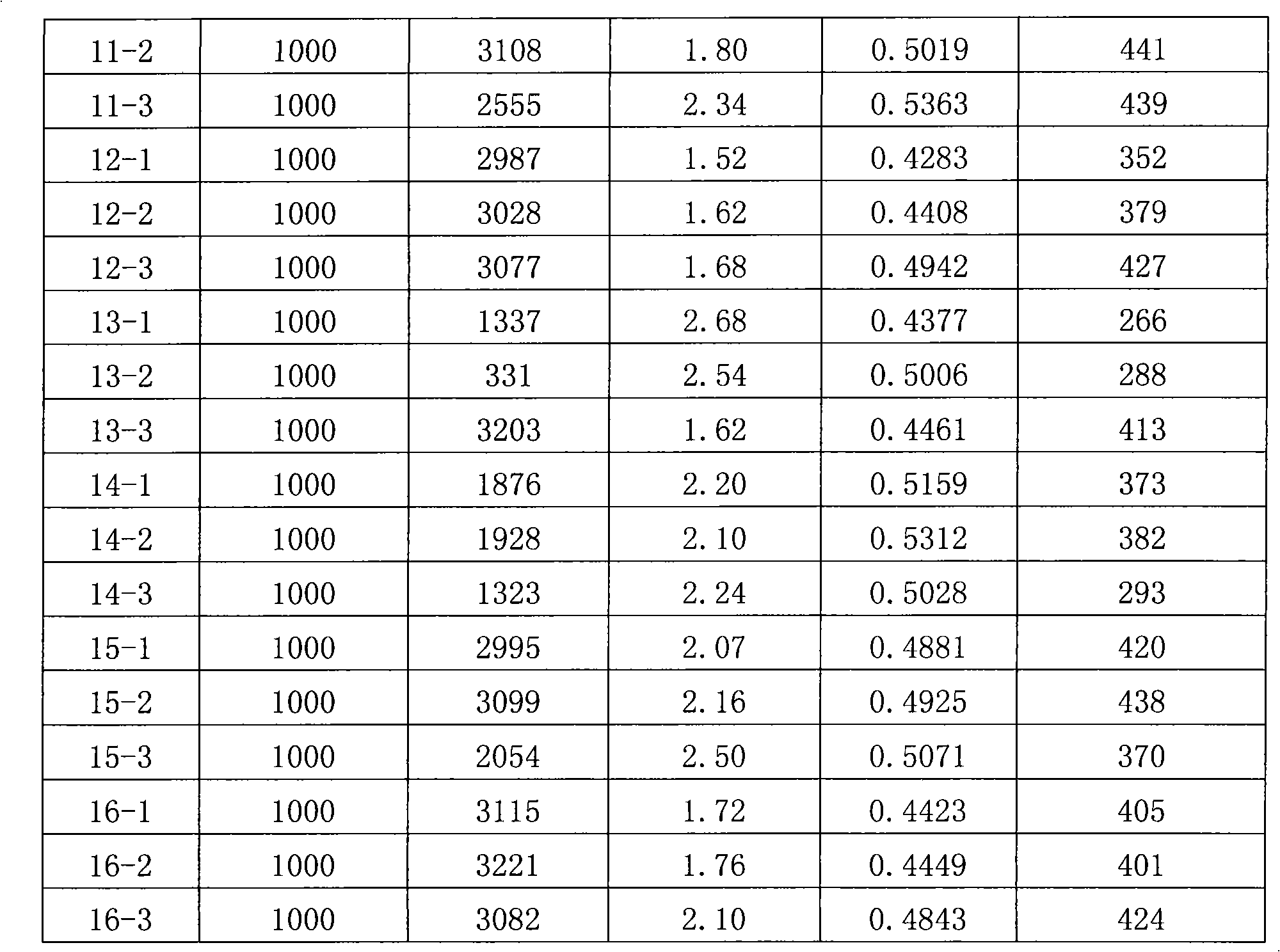

[0036] ZnNb prepared according to the precursor method 2 o 6 , and then using the traditional preparation method, the Pb 3 o 4 , ZnNb 2 o 6 , ZrO 2 、TiO 2 , La 2 o 3 The oxide powder is weighed according to the chemical ratio, ground in a mortar, sieved, put into a ball mill jar for ball milling for 4 hours, and dried; the dried powder is ground in a mortar, sieved, and granulated; single-axis Stress forming, molding pressure 200-250Mpa; green sheet diameter 12mm; green sheet is sintered at 1230-1270°C for 2 hours.

[0037] According to 0.3Pb(Zn 1 / 3 Nb 2 / 3 )O 3 -0.7Pb y La x (Zr z Ti m )O 3The stoichiometric ratio of x is 0.01, 0.03, 0.05, 0.07, y=1-x, z is 0.5, 0.51, 0.52, 0.53, m=1-z, and the sintering temperature is 1230°C, 1250°C, 1270°C .

[0038] x=0.01, z=0.5, the sintering temperature is 1230°C, 1250°C, 1270°C, respectively recorded as 1-1, 1-2, 1-3; x=0.03, z=0.5, the sintering temperature is 1230°C, 1250°C °C, 1270 °C, respectively recorded as 2-1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com