Method for preparing biodegradable oil residue fertilizer

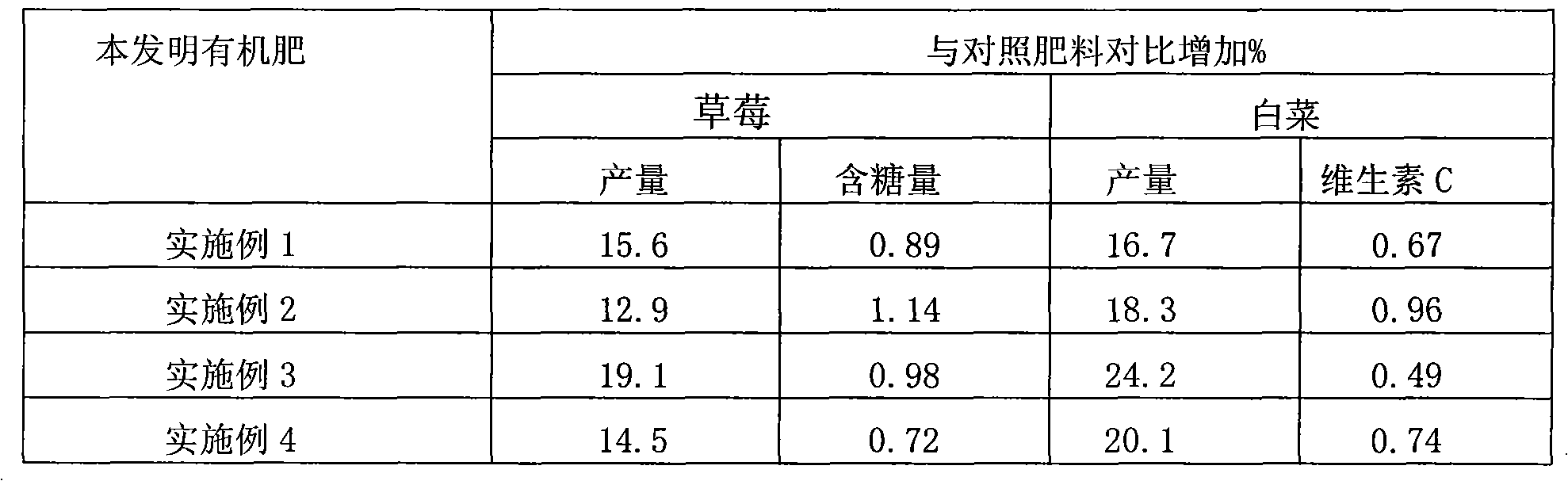

A technology of biodegradation and oil residue, applied in the direction of organic fertilizer, fertilizer form, fertilizer mixture, etc., can solve the problems of difficulty in crushing, hard dry oil residue, affecting fertilizer effect, etc., and achieve a good effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0008] A method for preparing a biodegradable oil residue fertilizer, comprising four fermentation liquids of Bacillus subtilis fermentation liquid, Yarrowia lipolytica fermentation liquid, Geotrichum candidum fermentation liquid and Lactobacillus plantarum fermentation liquid, characterized in that,

[0009] (1) The four strains of fermentation broth were respectively selected from the China Industrial Microorganism Culture Collection and Management Center. (Geotrichum candidum) No. 31418, Lactobacillus plantarum (Lactobacillus plantarum) No. 6026;

[0010] (2) According to parts by mass, get 100~150 parts of Bacillus subtilis fermented liquid, 100~150 parts of Yarrowia lipolytica fermented liquid and add in 1000 parts of oil residue, adjust water content 45~55wt%, pH 6.5~7.0, fully Mix well, control the temperature of the material at 35°C-40°C, and let it stand for 6-8 hours; pass in steam, and count when the temperature rises to 100°C, and keep it for 25-35 minutes.

[001...

specific Embodiment approach

[0035] The present invention will be further described below in conjunction with the examples, but not limited thereto.

[0036] Oil residue is the residue left after oil production by Shandong Everbright Sun Moon Co., Ltd., including soybean oil residue, peanut oil residue, cottonseed oil residue or rapeseed oil residue.

[0037]The strains used in the examples are: Bacillus Subtilis (Bacillus Subtilis) China Industrial Microorganism Preservation Management Center strain catalog number 10210, Yarrowia lipolytica (Yarrowia lipolytica) China Industrial Microorganism Preservation Management Center strain catalog number 1444, Baidi Mold (Geotrichum candidum) China Industrial Microbiology Collection Management Center strain catalog number 31418, Lactobacillus plantarum (Lactobacillus plantarum) China Industrial Microbiology Collection Management Center strain catalog number 6026, purchased from China Industrial Microbiology Culture Collection Management Center.

[0038] The amount...

Embodiment 1

[0040] (1) Preparation of Bacillus subtilis fermentation liquid

[0041] Take 200 grams of peeled potatoes, add 1000 grams of water and boil for 20 minutes, filter with gauze, add water to the filtrate to 1000 grams, then add 15 grams of glucose and 2 grams of peptone, heat until all ingredients are dissolved, and sterilize at 0.11 MPa for 30 minutes , prepared into a liquid medium, and the activated Bacillus subtilis and Yarrowia lipolytica were cultured for 2 days in a shaking flask at 28°C and 180 rpm; kg, 8 kg of glucose, 30 kg of oil residue, and 1000 kg of water in a fermenter, cultivated for 4 days at 28°C to obtain a Bacillus subtilis fermentation liquid.

[0042] (2) The preparation method of the Yarrowia lipolytica fermentation liquid is the same as that of the Bacillus subtilis fermentation liquid, except that the Yarrowia lipolytica strain is inserted.

[0043] (3) Take 150 kg of Bacillus subtilis fermentation liquid and 100 kg of Yarrowia lipolytica fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com