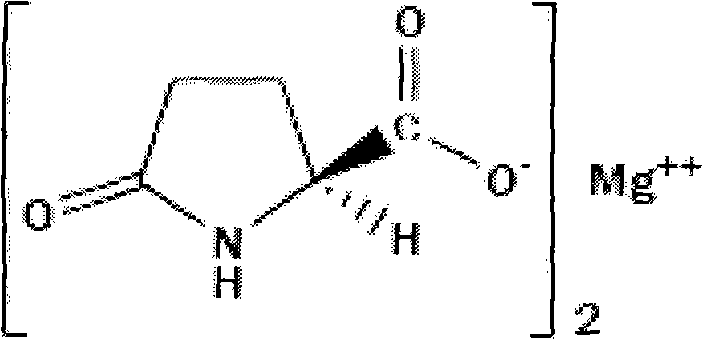

Method for preparing magnesium L-pyroglutamate

A technology for magnesium pyroglutamate and pyroglutamate, applied in the field of preparing L-magnesium pyroglutamate, which can solve the problems of no process reports, etc., and achieve the effects of simple operation, low cost and proper proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 small test program

[0026] The first step: dehydration to prepare L-pyroglutamic acid

[0027] Feed in a 3L stainless steel reactor: 300g of L-glutamic acid (food grade), 1200ml of deionized water and raise the temperature to 113°C-115°C, maintain it for 9 hours, and the reaction is complete. The coking rate can reach 96%, and the racemization rate can be controlled below 0.5%.

[0028] The second step: separation and extraction of pyroglutamic acid

[0029] After coking, cool the reaction solution to room temperature, add the same volume of deionized water to dilute the original volume twice, and directly put it on the 732 cation exchange resin column prepared in advance to separate L-pyroglutamic acid and uncoked L-glutamic acid .

[0030] The third step: preparation of magnesium L-pyroglutamate

[0031] Add the extracted L-pyroglutamic acid solution in a 5000ml beaker, stir and heat, when the temperature rises to 70°C, add 69g of magnesium carbonate...

Embodiment 2

[0033] Example 2 pilot test program

[0034] The first step: dehydration to prepare L-pyroglutamic acid

[0035] Feed in a 2-ton stainless steel reactor: L-glutamic acid (food grade) 300kg, deionized water 1500L, heat up to 116°C-118°C, maintain for 8 hours, and the reaction is complete. The coking rate can reach 96%, and the racemization rate can be controlled below 0.5%.

[0036] The second step: Separation and extraction of L-pyroglutamic acid

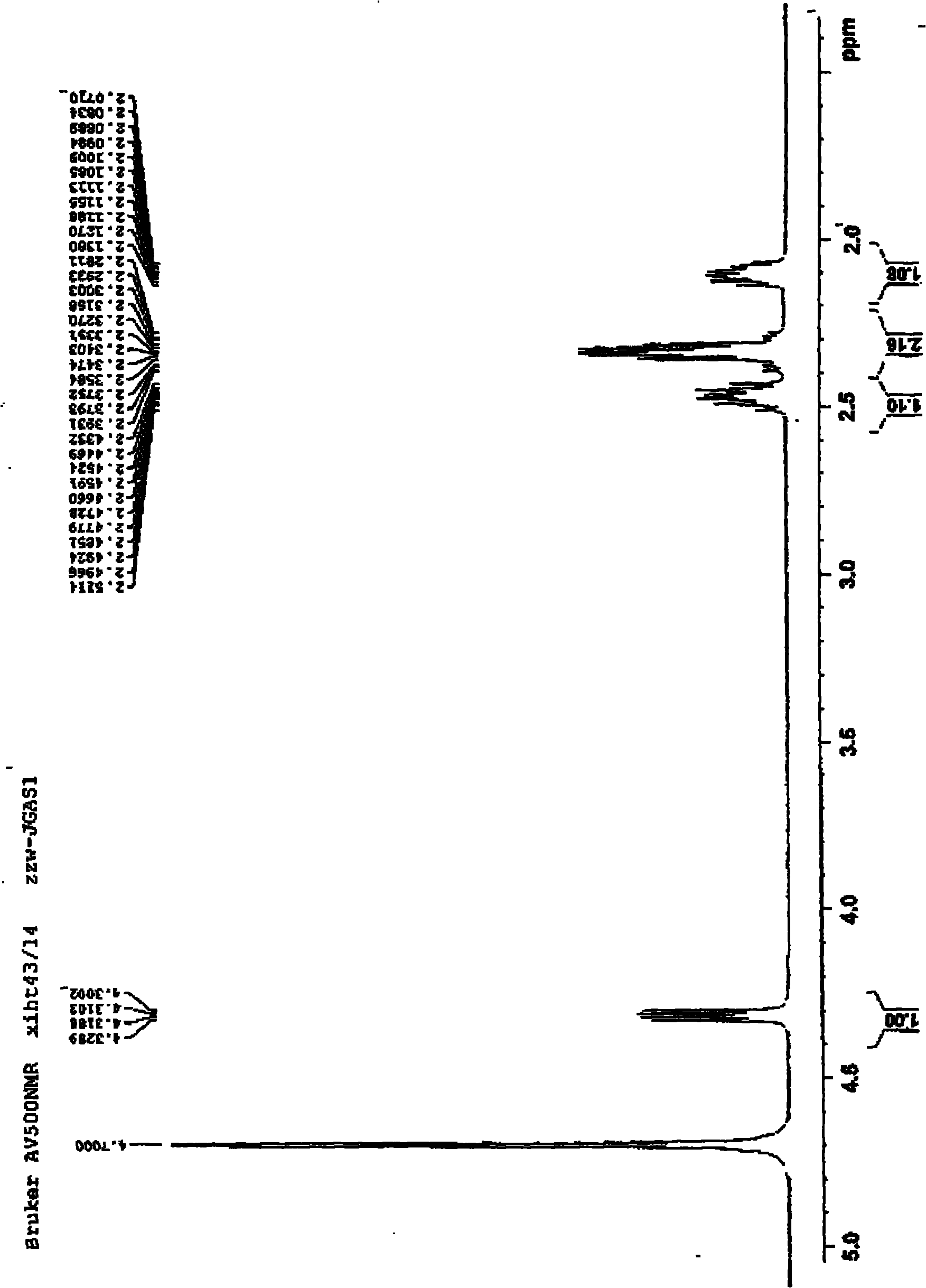

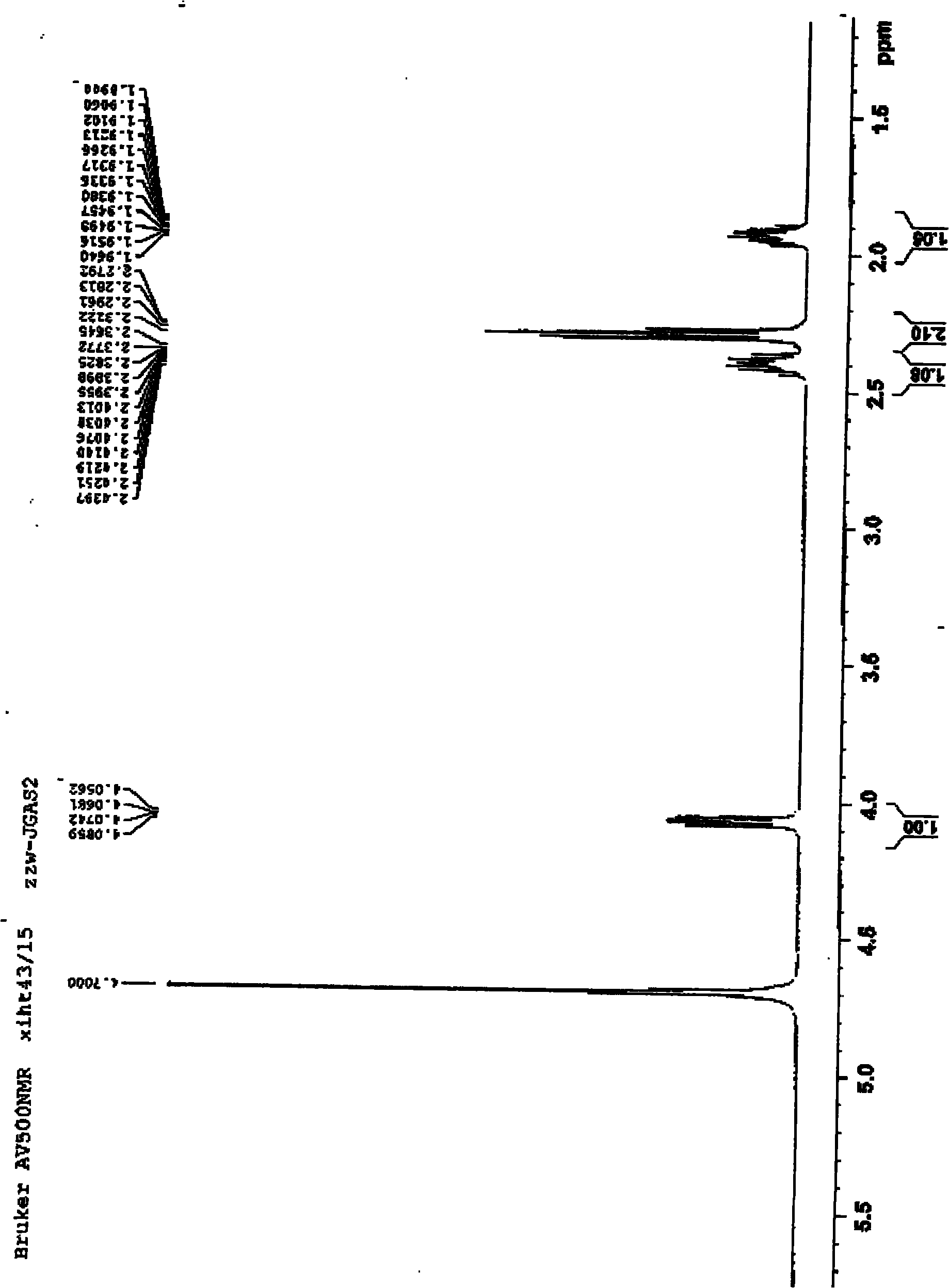

[0037] After coking, cool the reaction solution to room temperature, add deionized water to dilute the original volume by 2.5 times, and directly put it on the 732 cation exchange resin column prepared in advance to separate L-pyroglutamic acid and uncoked L-glutamic acid. The isolated L-pyroglutamic acid NMR spectrum is shown in figure 1 .

[0038] The third step: preparation of magnesium L-pyroglutamate

[0039] Add the extracted L-pyroglutamic acid solution in a 5-ton enamel batching tank, stir and heat, and when the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com