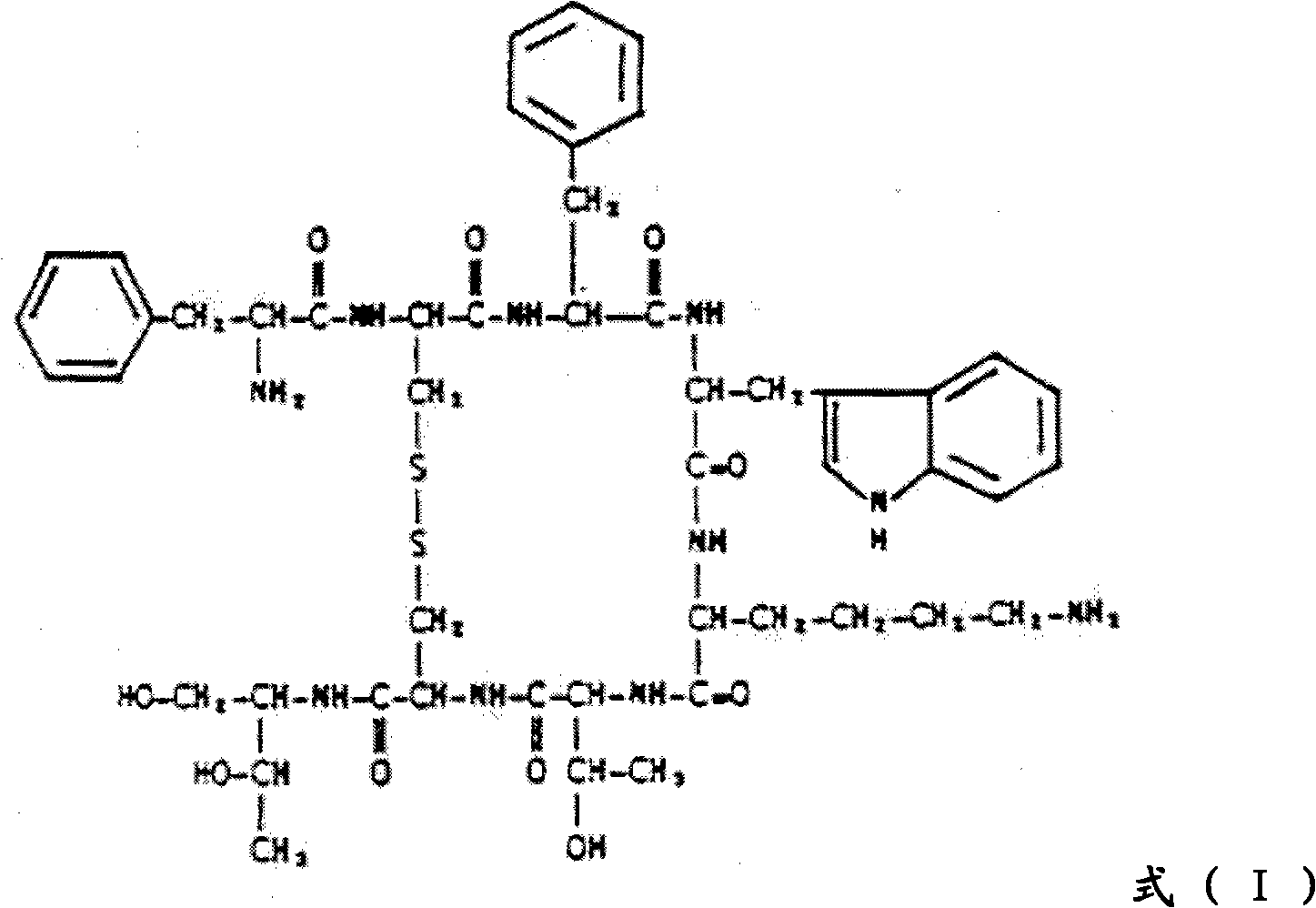

Preparation method of octreotide

A technology of octreotide and crude peptide, which is applied in the field of solid-phase synthesis of octreotide, can solve the problems of carcinogenic by-products and low yield of octreotide, and achieve the effect of increasing product yield and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The abbreviations used in the present invention have the following meanings:

[0029] Boc: tert-butoxycarbonyl; tBu: tert-butyl; BOP: benzotriazol-1-yloxytris(dimethylamino)phosphonium hexafluorophosphate; Bzl: benzyl; 2-CTC: 2 -Chlorotrityl; DCM: dichloromethane; DIC: N,N-diisopropylcarbodiimide; DIPEA: N,N-diisopropylethylamine; DMF: N,N-dimethyl Formamide; EDT: 1,2-ethanedithiol; Fmoc: 9-fluorenylmethoxycarbonyl; HOBt: 1-hydroxybenzotriazole; TFA: trifluoroacetic acid; Trt: trityl; Z: benzyl Oxycarbonyl;

[0030] Fmoc-AA-OH: amino acid protected by N-fluorenylmethoxycarbonyl;

[0031] Fmoc-Cys(Trt)-OH: N-fluorenylmethoxycarbonyl-S-tritylcysteine;

[0032] Fmoc-Lys(Boc)-OH: N-α-fluorenylmethoxycarbonyl-N-ε-tert-butoxycarbonyllysine;

[0033] Fmoc-Phe-OH: N-fluorenylmethoxycarbonyl-phenylalanine;

[0034] Fmoc-D-Phe-OH: N-fluorenylmethoxycarbonyl-D-phenylalanine;

[0035] Fmoc-Thr(tBu)-OL: N-fluorenylmethoxycarbonyl-O-tert-butylthreoninol;

[0036] Fmoc-Thr(tBu)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com