Lithium ion power battery explosion protection cover

A power battery and explosion-proof cover technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of copper foil film and battery electrolyte easily corroding, reducing battery performance level, and existing safety hazards, etc. Novel, harm reduction, high safety level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

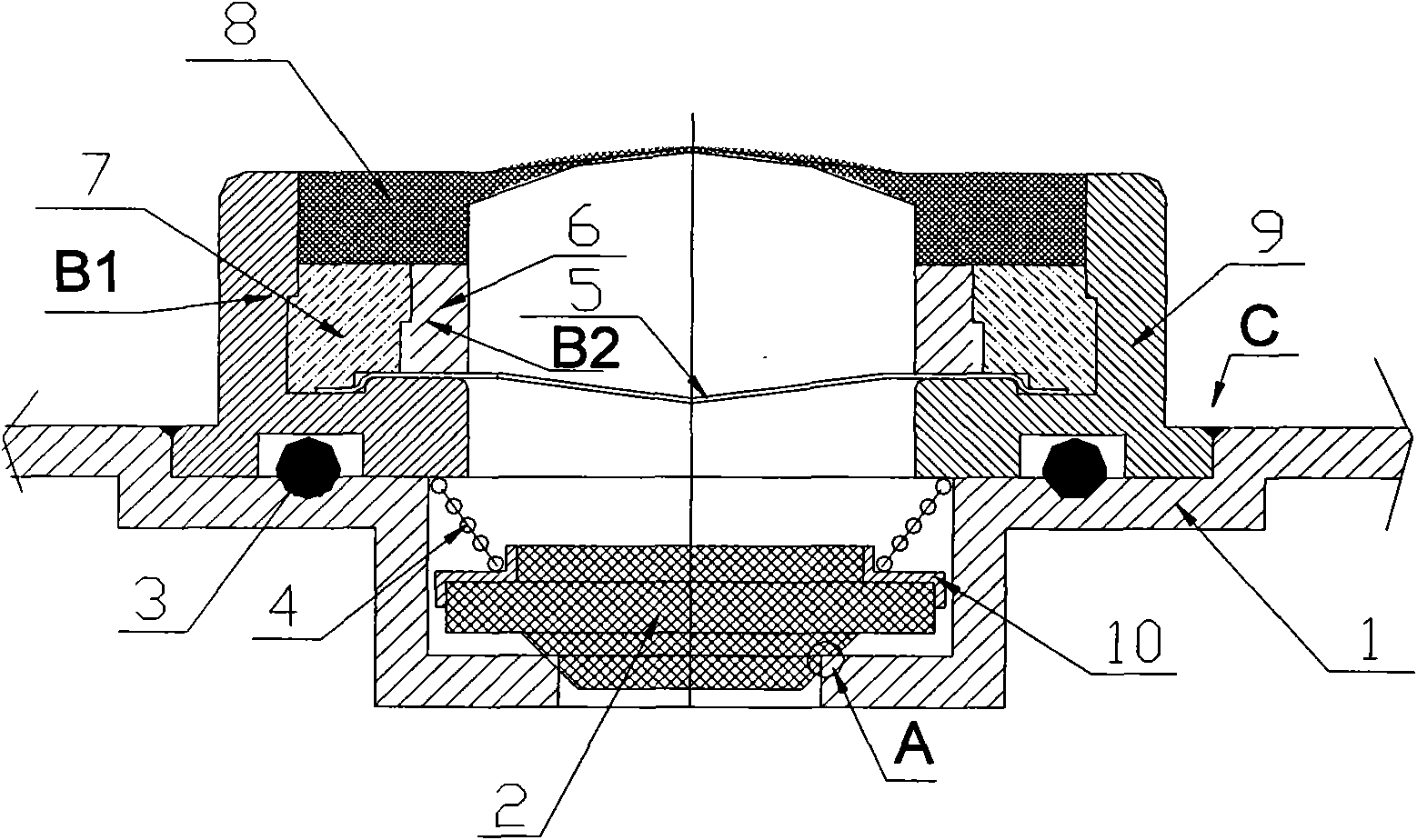

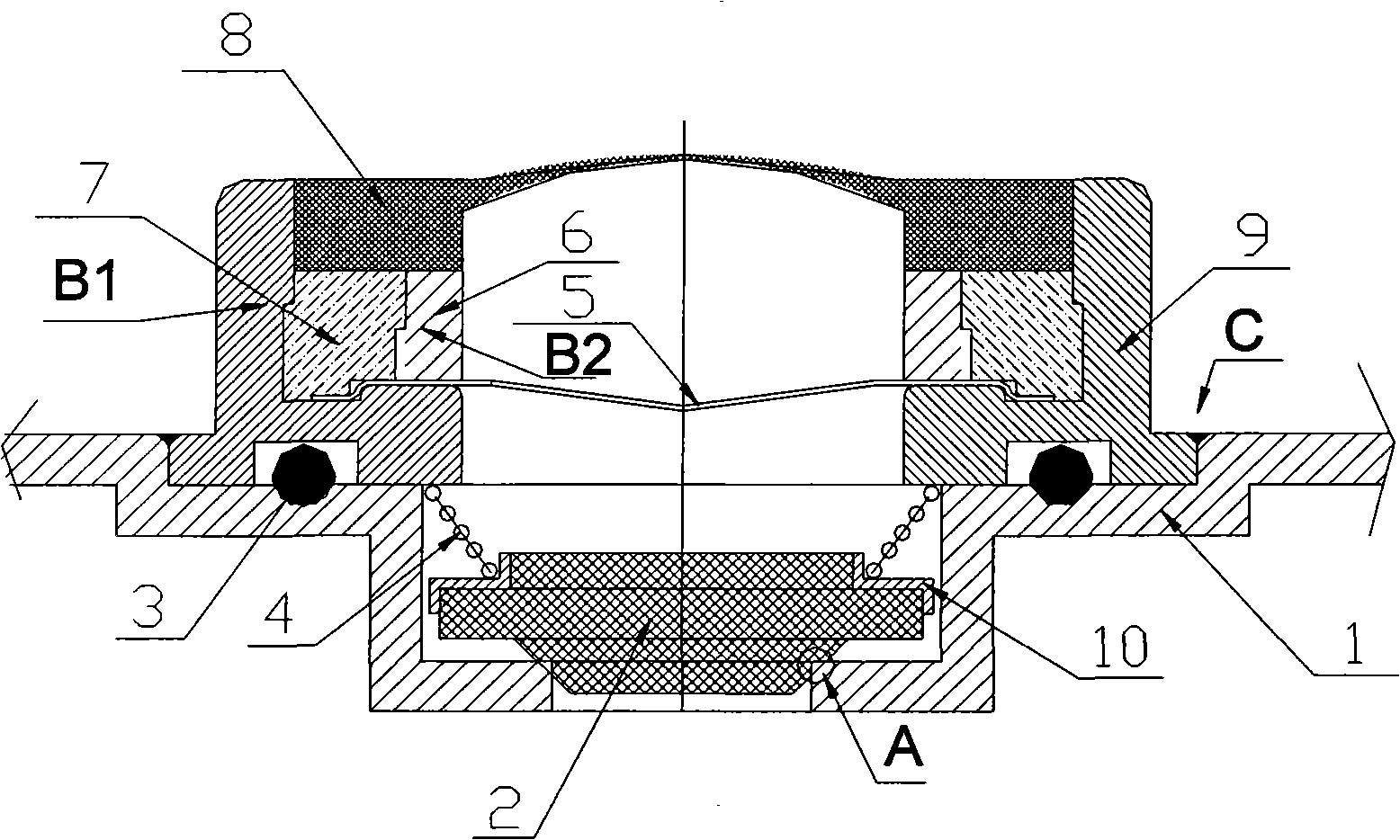

[0022] An explosion-proof cap for a lithium-ion power battery comprises a cover plate and an explosion-proof film, and the cover plate is provided with an explosion-proof hole. The explosion-proof hole of the cover plate is located at the bottom of the sinking platform of the cover plate, which is a φ6-φ12mm round hole. There is a rubber sealing plug at the explosion-proof hole of the cover plate, and a tower-shaped pressure spring is installed on the rubber sealing plug. A sealing plug gland 10 is provided at the joint between the tower spring and the rubber sealing plug.

[0023] An explosion-proof diaphragm is arranged on the cover plate, and the explosion-proof diaphragm is assembled by a burst diaphragm base, a burst bush and sealed soft aluminum. The bursting disc base, the bursting bushing and the upper part of the sealed soft aluminum are equipped with an outer protective rubber membrane. A rubber sealing ring is installed between the bursting diaphragm base and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com