Environment-friendly graphite resistance paste and preparation method thereof

A graphite resistor, an environmentally friendly technology, applied in the direction of heating element materials, etc., can solve the problems of poor stability of the mica board, harmfulness of the resistance slurry to the human body, poor matching of the mica board, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

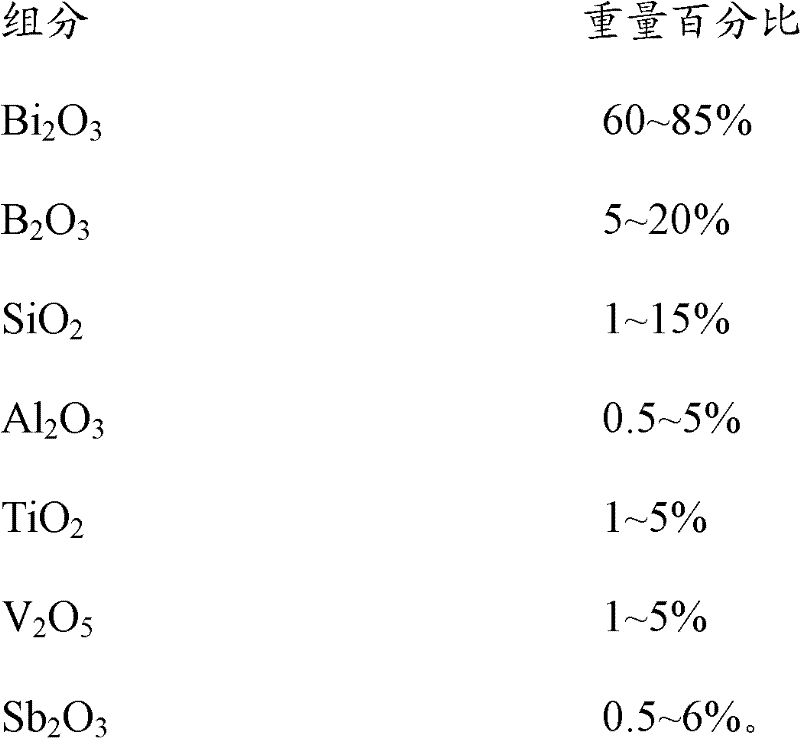

[0025] 1) Preparation of lead-free glass powder: take 60% Bi by weight percentage 2 o 3 , 20% of B 2 o 3 , 10% SiO 2 , 4% Al 2 o 3 , 3% TiO 2 , 2% of V 2 o 5 , and 1% Sb 2 o 3 , grind it into powder and pass through a 80-mesh sieve, then mix it evenly in a mixer and put it in a mortar, then transfer it to a high-temperature resistance furnace, keep it at 900°C for 30 minutes, and then take it out and immerse it in cold water for water Quenching to obtain glass slag, then put the above-mentioned obtained glass slag into a ball mill and mill for 4 hours to form glass powder, and finally pass the ball-ground glass powder through 400 sieves, then dry to obtain lead-free glass powder for use.

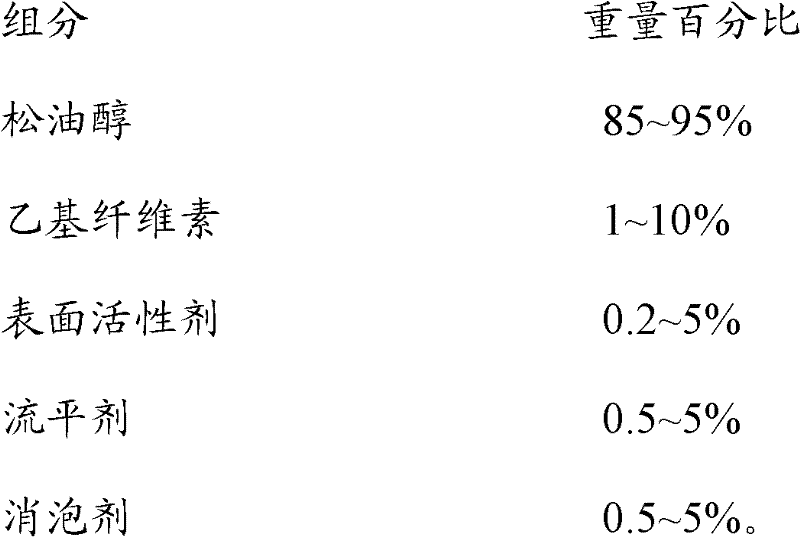

[0026] 2) Preparation of organic vehicle: take by weight 85% terpineol, 10% ethyl cellulose, 0.2% diethanolamide monoglyceride stearate as surfactant, 3.5% as leveling agent polydimethylsiloxane, and 1.3% polyethyl ether modified siloxane as a defoamer, put them in a beaker, and r...

Embodiment 2

[0029] 1) Preparation of lead-free glass powder: take 62% Bi by weight percentage 2 o 3 , 15% B 2 o 3 , 13% SiO 2 , 2.5% Al 2 o 3 , 2% TiO 2 , 5% of V 2 o 5 , and 0.5% Sb 2 o 3 , grind it into powder and pass through 80-mesh sieve, mix it evenly in a mixer, put it in a mortar, transfer it to a high-temperature resistance furnace, keep it at 930°C for 30 minutes, and then take it out and immerse it in cold water for water quenching , to obtain glass slag, then put the glass slag obtained above into a ball mill and ball mill for 4 hours to become glass powder, and finally pass the ball-ground glass powder through 400 sieves, then dry to obtain lead-free glass powder for use.

[0030] 2) Preparation of organic carrier: take by weight 85% terpineol, 8% ethyl cellulose, 1% nonylphenol polyoxyethylene as surfactant, 5% polyformaldehyde as leveling agent Phenyl phenyl siloxane, and 1% polyether modified siloxane as a defoamer, put into a beaker, react in a water bath at 90...

Embodiment 3

[0033]1) Preparation of lead-free glass powder: take 65% Bi by weight percentage 2 o 3 , 17% B 2 o 3 , 5% SiO 2 , 3% Al 2 o 3 , 1% TiO 2 , 4% of V 2 o 5 , and 5% Sb 2 o 3 , grind it into powder and pass through 80-mesh sieve, mix it evenly in a mixer, put it in a mortar, transfer it to a high-temperature resistance furnace, keep it at 950°C for 30 minutes, and then take it out and immerse it in cold water for water quenching , to obtain glass slag, then put the glass slag obtained above into a ball mill and ball mill for 4 hours to become glass powder, and finally pass the ball-ground glass powder through 400 sieves, then dry to obtain lead-free glass powder for use.

[0034] 2) Preparation of organic carrier: take by weight 86.5% terpineol, 7.5% ethyl cellulose, 5% fatty alcohol polyoxyethylene ether as surfactant, 0.5% organic base as leveling agent Modified polysiloxane, and 0.5% polyether modified siloxane as a defoaming agent, put them in a beaker, react in a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com