Millstone for processing crystal and manufacturing method thereof

A manufacturing method and technology of grinding discs, which are applied to metal processing equipment, abrasive materials, grinding devices, etc., can solve the problems of high cost, waste, and large pollution of plating solution, and achieve the goals of increasing service life, reducing pollution, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

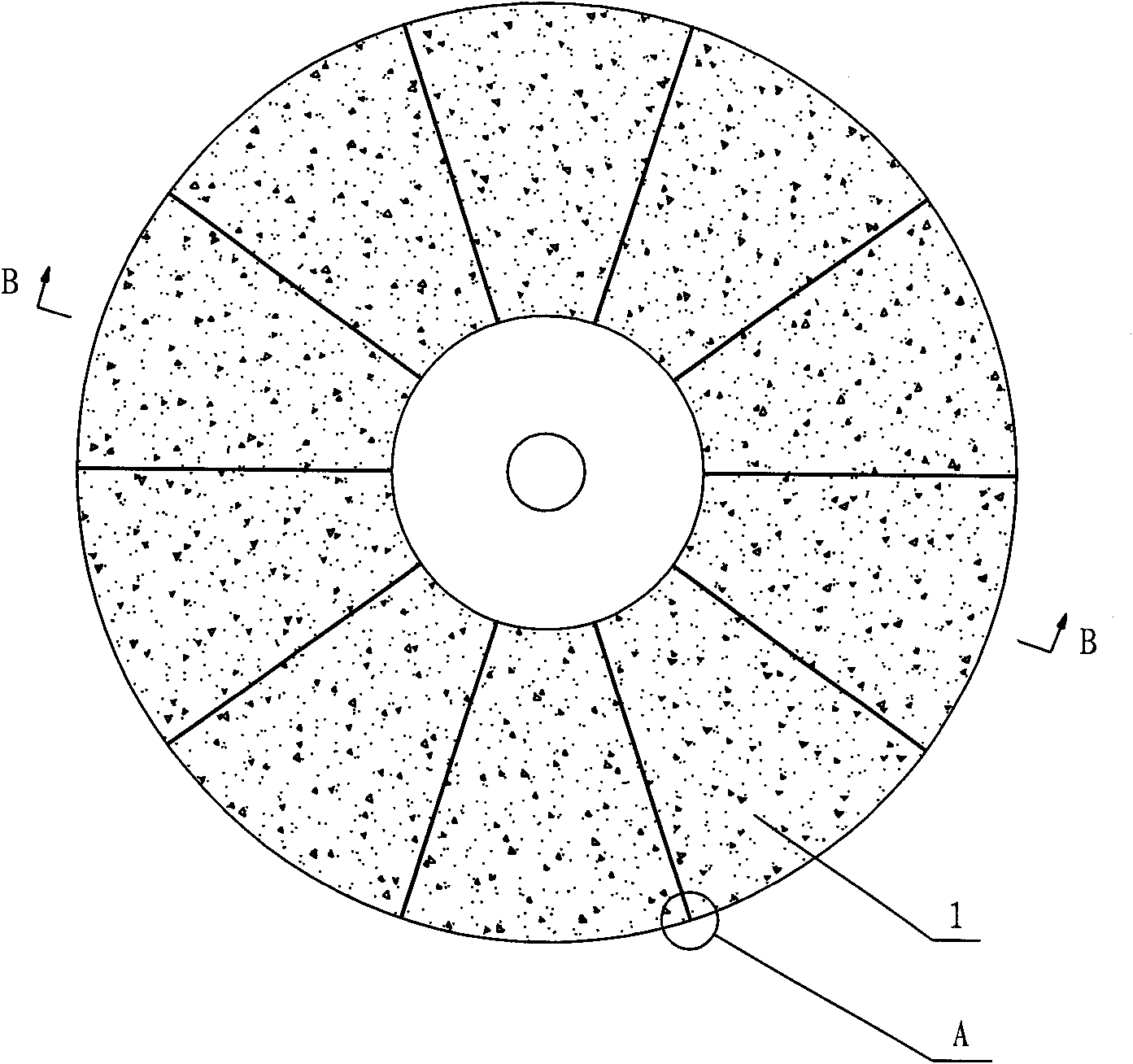

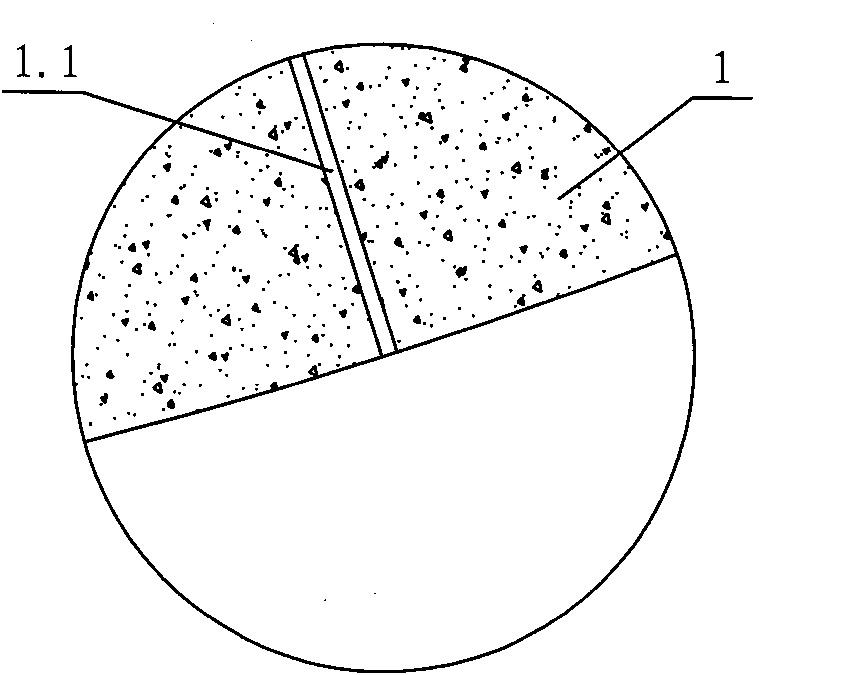

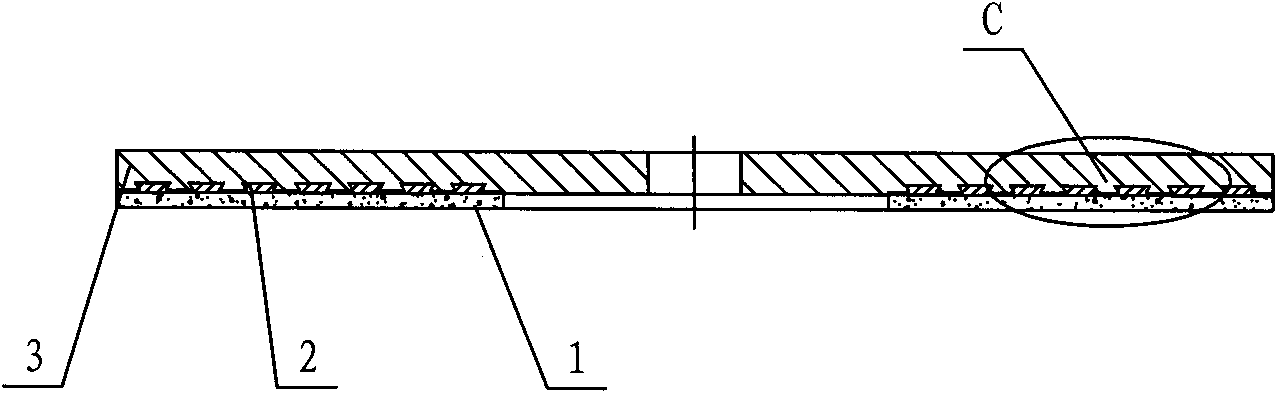

[0032] see Figure 1-Figure 6 , a grinding disc used for processing crystals, including a diamond cutter head 1 arranged on a substrate 3, the substrate 3 is an aluminum substrate, and more than one assembly groove 3.1 is arranged on the substrate 3, and the diamond cutter head is connected to the substrate through a bonding layer 2 catch. The diamond cutter heads 1 are distributed in strips, and chip removal grooves 1.1 are arranged between adjacent diamond cutter heads 1 . The assembly groove 3.1 is arranged on the base body 3 in a ring shape; or the assembly groove is arranged on the base body in a spoke shape.

[0033] The material components of the diamond segment 1 include iron-copper pre-alloyed powder, copper-tin pre-alloyed powder and diamond. The material components of the diamond cutter head 1 are calculated by weight percentage, the iron-copper pre-alloy powder is 10-50%, and the copper-tin pre-alloy powder is 50-90%. When the iron-copper pre-alloy powder and the...

no. 2 example

[0047] When making a millstone, the following steps are involved:

[0048] In the first step, first weigh 35 grams of iron-copper pre-alloy powder and 65 grams of copper-tin pre-alloy powder, and mix them uniformly to obtain a mixture; then weigh 3 grams of diamond, put the diamond into the mixture, and mix uniformly to obtain a mixture material, then add paraffin oil to the mixture, and finally mix evenly in a three-dimensional mixer to obtain the material to be used, wherein the paraffin oil is 0.2-0.4% of the total weight of the mixture.

[0049] In this embodiment, the weight ratio of iron and copper in the iron-copper pre-alloyed powder is 3:2, and the weight ratio of copper and tin in the copper-tin pre-alloyed powder is 17:3. The weight ratio of isopropanol, acetone and GB600 is 30:5:1. See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

no. 3 example

[0051] When making a millstone, the following steps are involved:

[0052] In the first step, first weigh 10 grams of iron-copper pre-alloy powder and 90 grams of copper-tin pre-alloy powder, and mix them uniformly to obtain a mixture; then weigh 3.5 grams of diamond, put the diamond into the mixture, and mix uniformly to obtain a mixture material, then add paraffin oil to the mixture, and finally mix evenly in a three-dimensional mixer to obtain the material to be used, wherein the paraffin oil is 0.2-0.4% of the total weight of the mixture.

[0053] In this embodiment, the weight ratio of iron and copper in the iron-copper pre-alloyed powder is 3:1, and the weight ratio of copper and tin in the copper-tin pre-alloyed powder is 9:1. The weight ratio of isopropanol, acetone and GB600 is 30:5:1. See the first embodiment for the rest of the undescribed parts, and will not repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com