Method for controlling acquisition of alloy films on multi-arc ion plating machine and proportional regulator thereof

A proportional regulator and multi-arc ion technology, applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve the problems of target craters, insufficient quantification, and precision control. To achieve the effect of reducing the number of droplets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

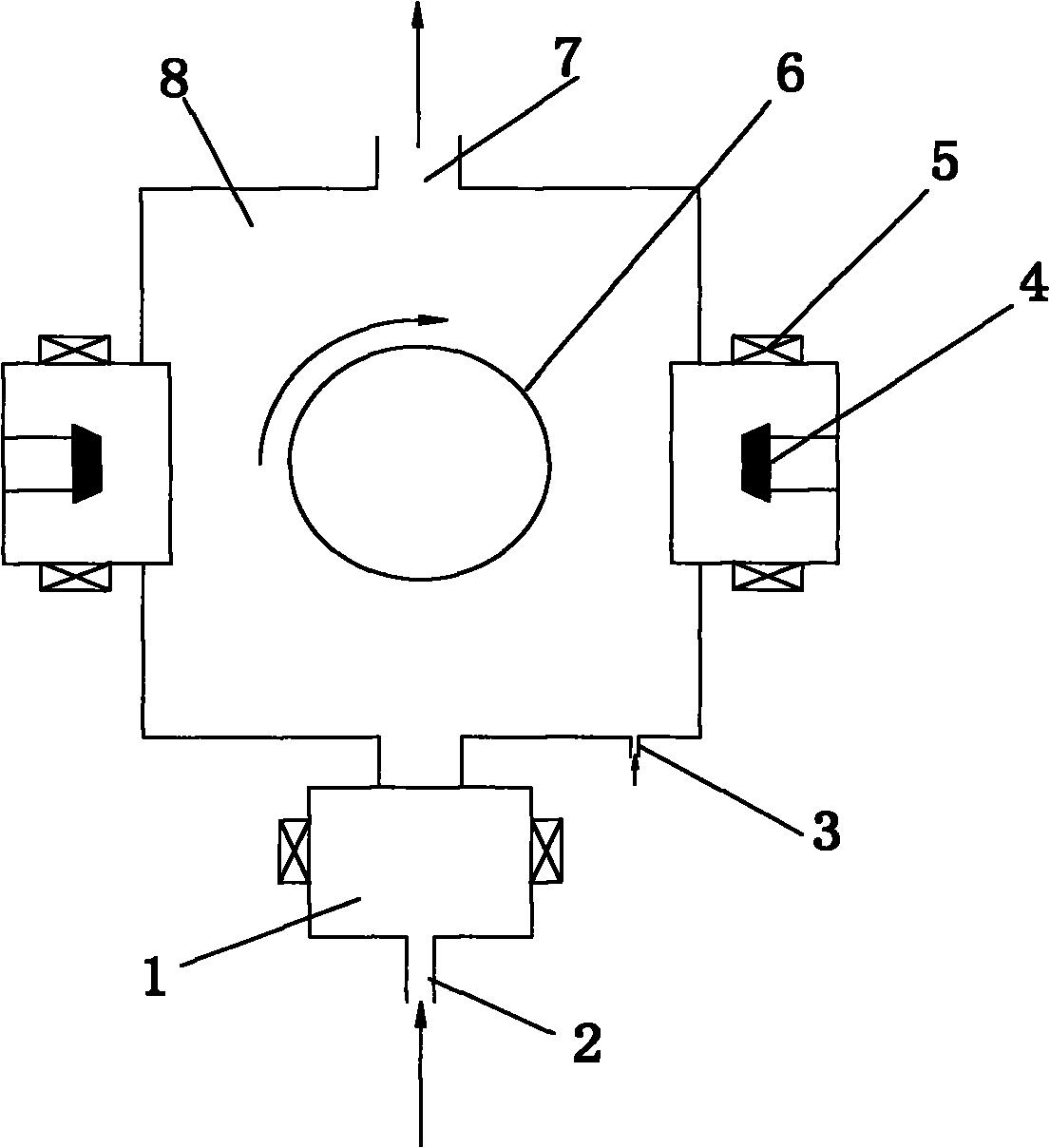

[0036] Working principle of the present invention is:

[0037] First, install different kinds of pure metal targets on two opposite cathode target positions of the multi-arc ion coating equipment;

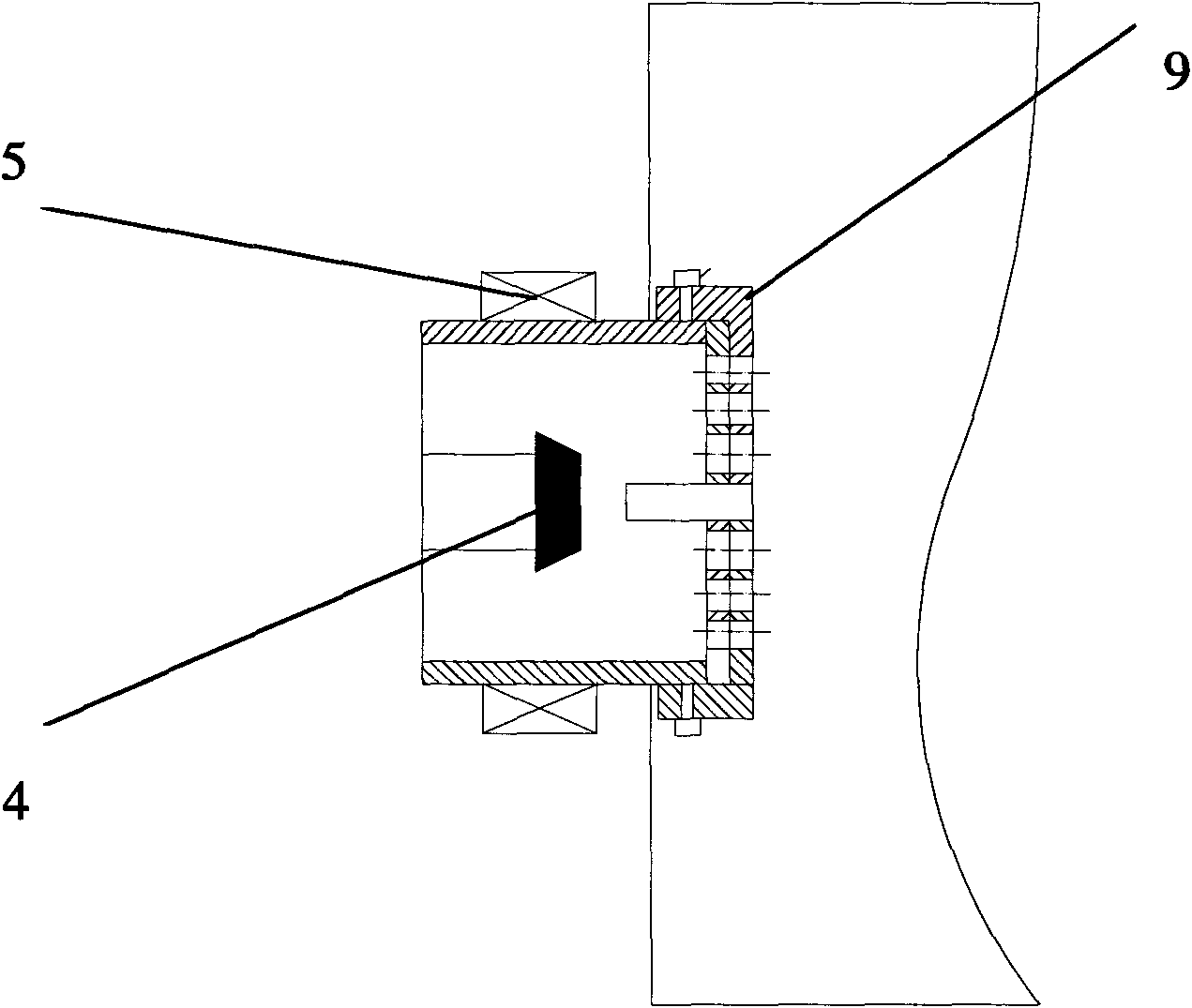

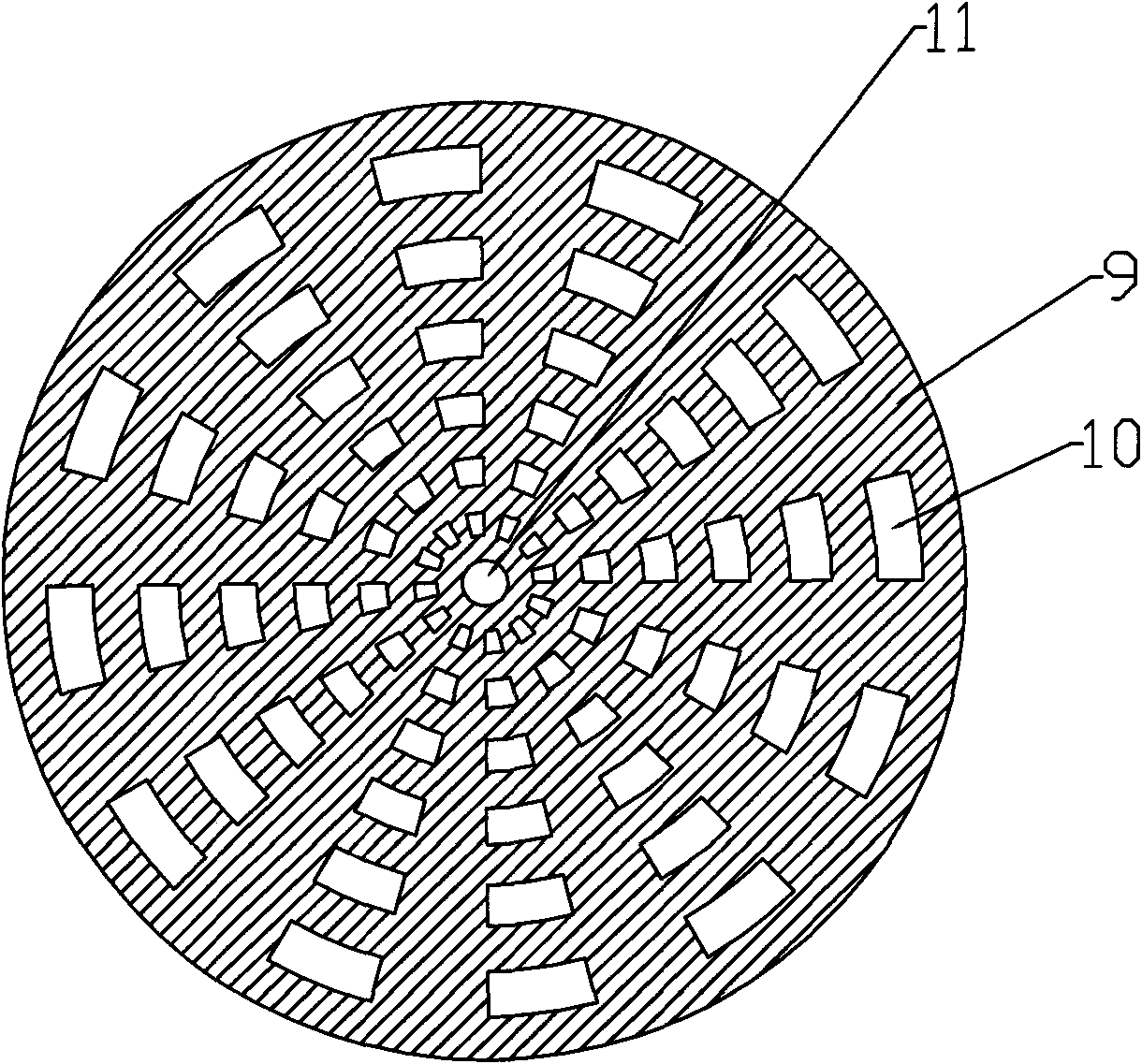

[0038] Secondly, in front of one of the vacuum cathode targets, a proportional regulator to adjust the flow rate of the sub-sieve cathode plasma is installed. The proportional regulator is a double-layer circular baffle with ring holes, and the ring of the two baffles The holes are the same, and occupy a certain proportion of the entire circular baffle, and the centers of the two baffles are equipped with guide posts and guide sleeves that allow them to rotate with each other; the rotation angle of the double-layer circular baffle of the proportional regulator can be adjusted;

[0039] During operation, the flux of cathode plasma can be adjusted by adjusting the rotation angle of the two plates of the proportional regulator, thereby controlling the proportion of components in the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com