C3 fraction selective hydrogenation catalyst and preparation method thereof

A technology for catalysts and metal catalysts, which is applied in catalyst activation/preparation, hydrogenation to hydrocarbons, chemical instruments and methods, etc., can solve the problems of high catalyst Pd content, high catalyst cost, and waste gas generation, and reduce the content of active metal components. , the effect of reducing the emission of gas pollutants and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

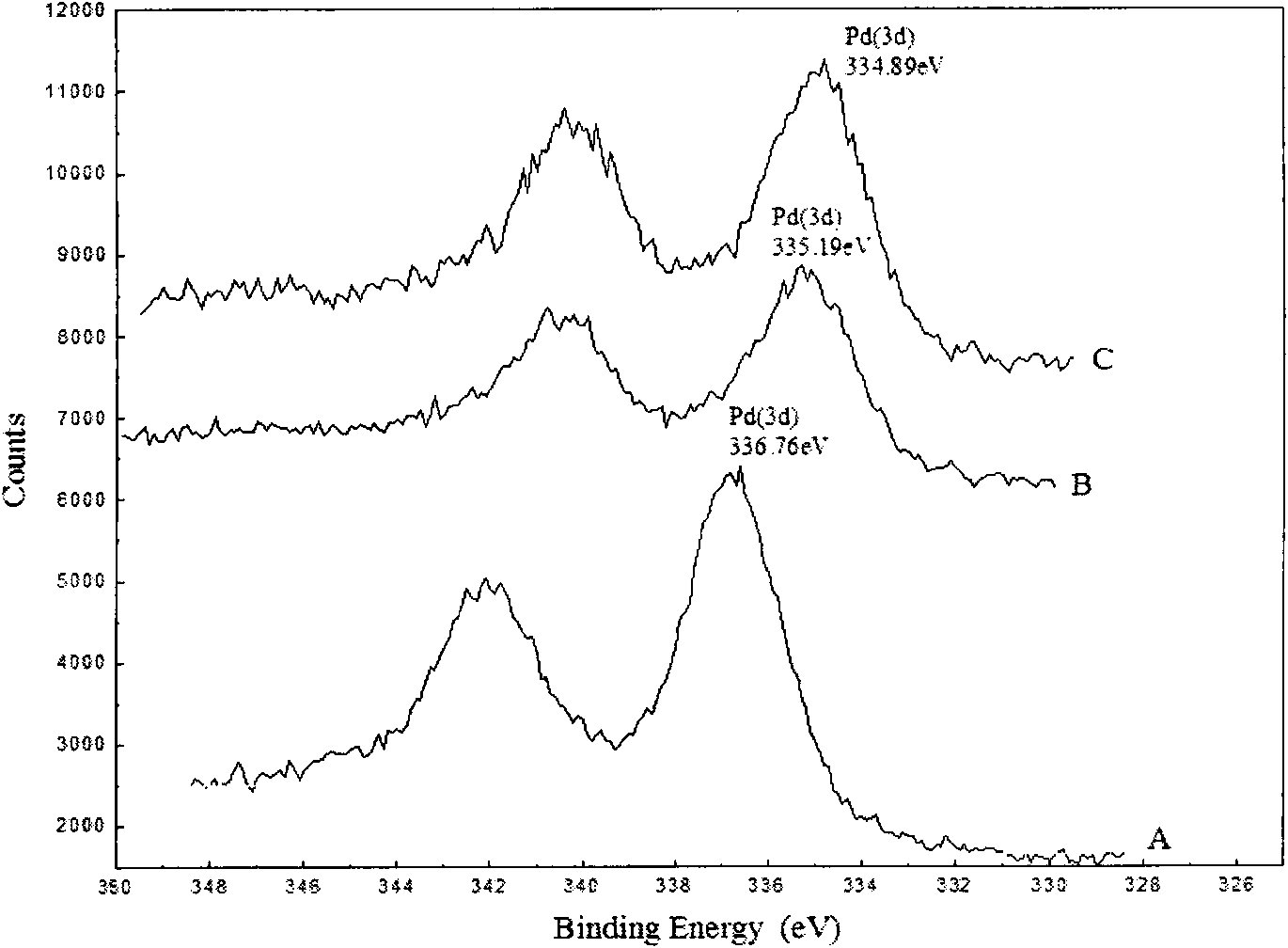

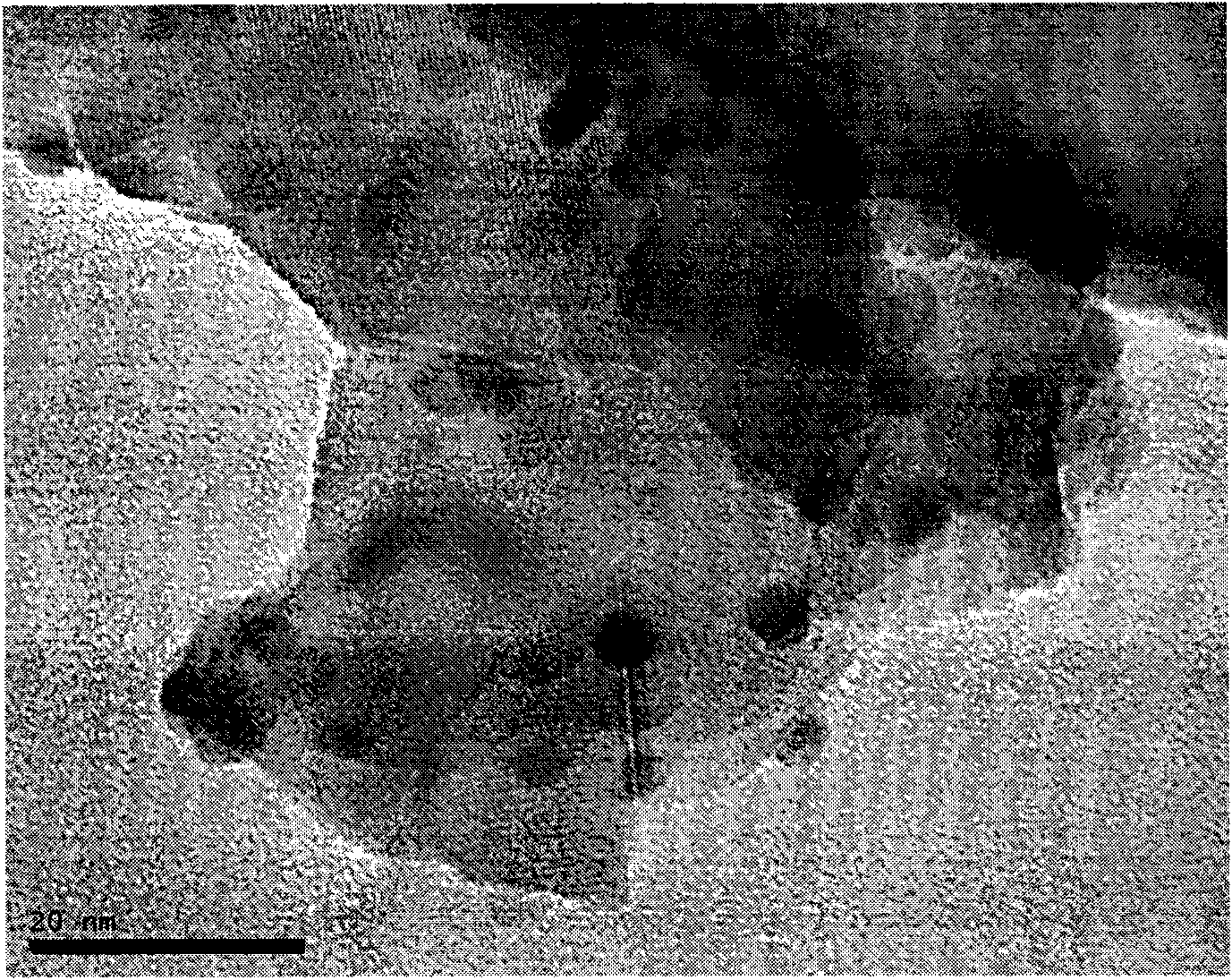

Embodiment 1

[0047] Weigh PdCl with a concentration of 10mg Pd / ml 2 10ml of the solution was diluted to 35ml with deionized water, adjusted to a pH of 4.3 with 1mol / L NaOH solution, and then diluted to 46.5g. Weigh the tooth shape Al 2 o 3 Carrier 100g, used Al 2 o 3 The specific surface area of the carrier is 52m 2 / g, the average pore diameter is 30nm, the pore volume is 0.47ml / g, and the prepared PdCl is sprayed on it 2 solution. Take a mixed solution prepared by 20ml of water and 20ml of isopropanol, pour it into the carrier loaded with Pd, disperse evenly, and pour out the excess solution. Use the product under vacuum 60 The Coγ radiation source was irradiated at a dose rate of 30Gy / min for 15h. The irradiated sample was dried at 120° C. for 6 h to obtain catalyst A with a Pd content of 0.1%.

Embodiment 2

[0049] Take the PdCl 2 The amount of the solution was changed to 13.5ml, and the rest of the operations were the same as in Example 1 to obtain catalyst B with a Pd content of 0.135%.

Embodiment 3

[0051] Weigh 10mg Pd / ml of Pd(NO 3 ) 2 Solution 10ml, add 10mg Ag / ml AgNO 3 Solution 20ml, using deionized water to dilute the mixed solution to 46.5g. Weigh the tooth shape Al 2 o 3 Carrier 100g, used Al 2 o 3 The specific surface area of the carrier is 52m 2 / g, the average pore diameter is 30nm, and the pore volume is 0.47ml / g, and the prepared Pd-Ag mixed solution is sprayed on it. Take 9ml of 1mo / L NaOH solution, dilute it to 18ml with deionized water, and spray it on the carrier containing Pd and Ag prepared above. Take the mixed solution prepared by 20ml of water and 20ml of isopropanol, pour it into the product prepared in the above two steps, disperse evenly and pour out the excess solution. The resulting product was used under vacuum 60 The Coγ radiation source was irradiated at a dose rate of 30Gy / min for 15h. The irradiated sample was dried at 120° C. for 6 h to obtain catalyst C with a Pd content of 0.1% and an Ag content of 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com