Method for enhancing yield of bacillus fermentation poly-gamma-glutamate by utilizing environmental pressure

A technology of environmental pressure and glutamic acid, applied in the field of microbial fermentation, to achieve the effects of easy operation, simple fermentation operation and significant production increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

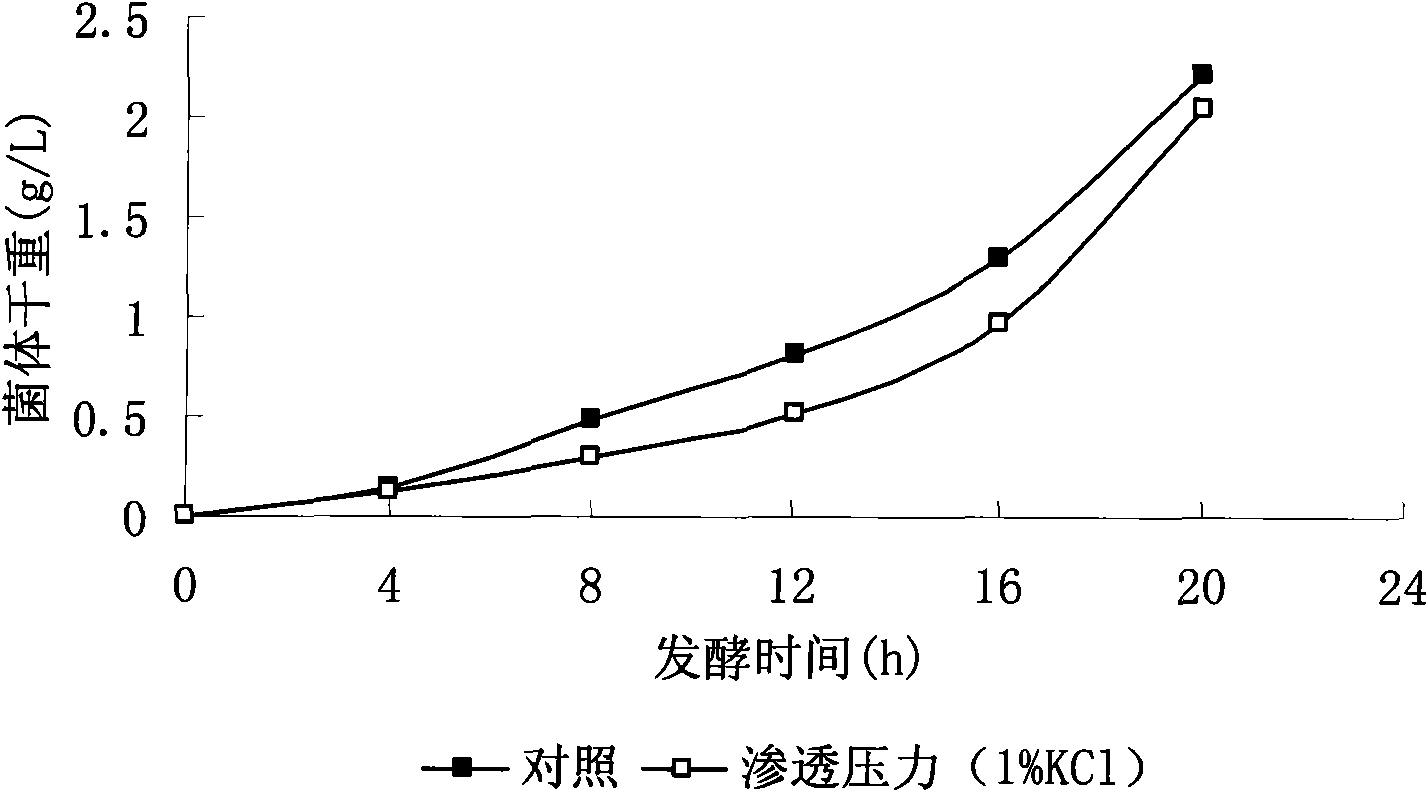

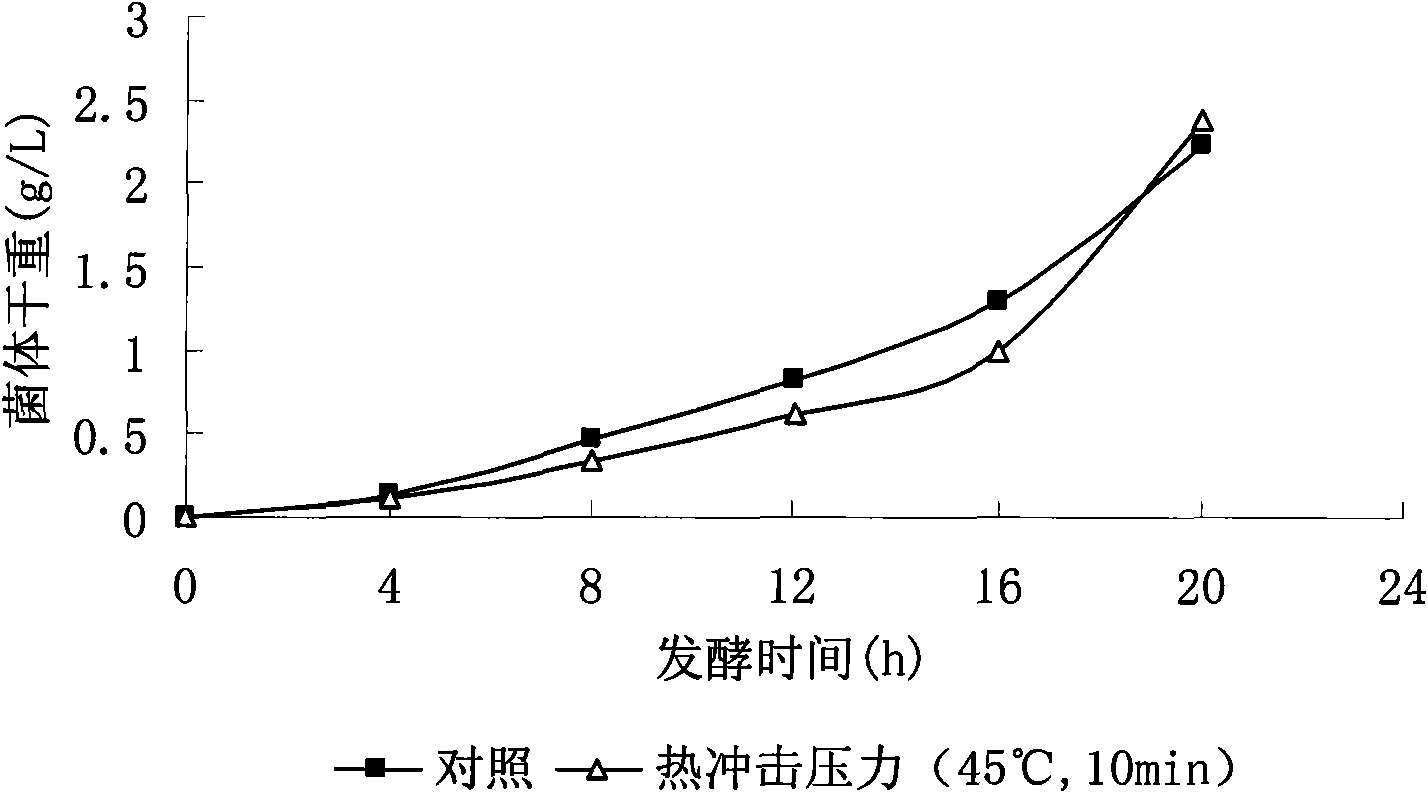

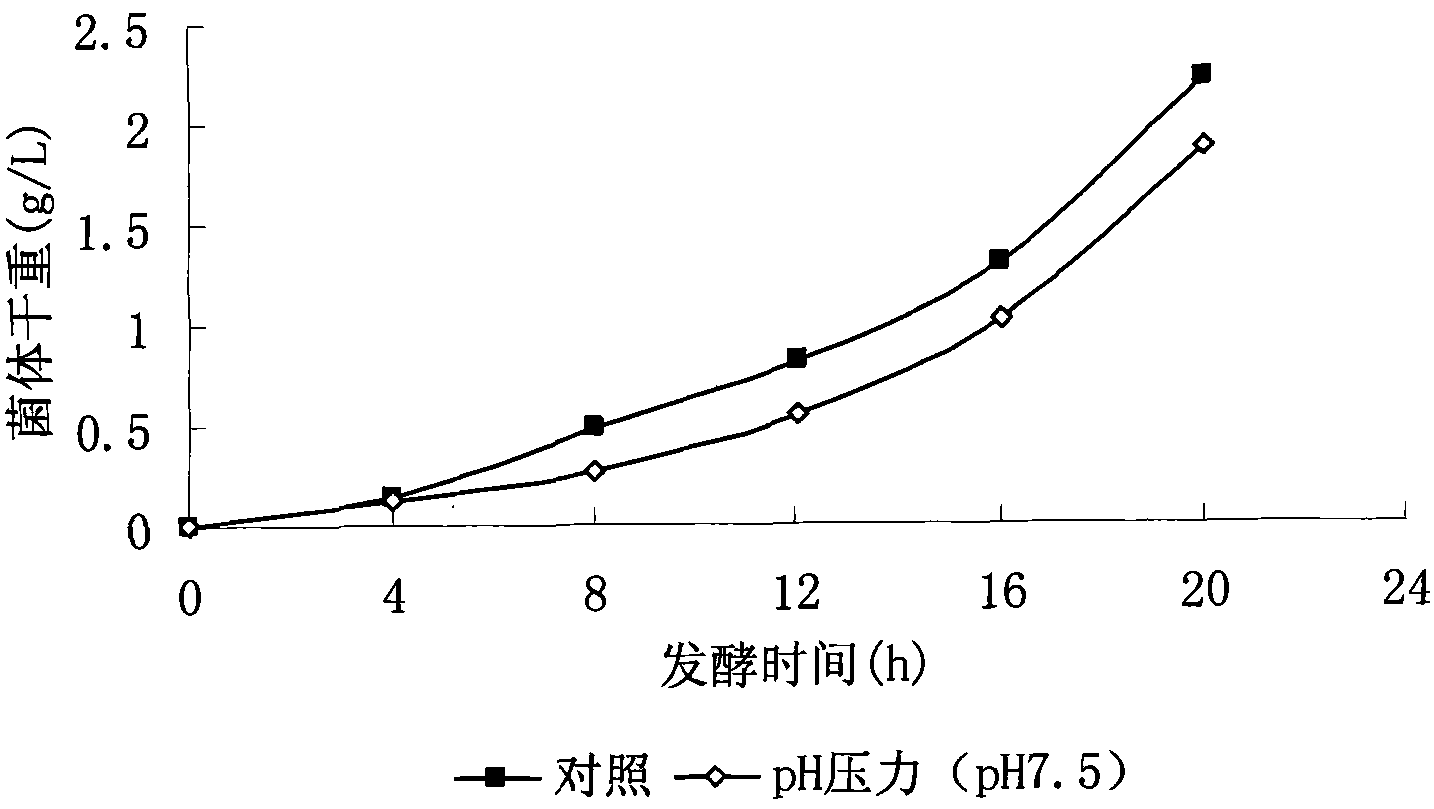

[0017] Example 1 Improvement of poly-γ-glutamic acid production by potassium ion-mediated osmotic pressure

[0018] (1) The strain Bacillus licheniformis WX-02 (see CCTCC M208065 in "Summary of the Invention") preserved by freezing is used as the production strain, and the relevant information of the strain is as follows:

[0019] Identification of Bacillus licheniformis WX-02

[0020] 1. Morphological characteristics of strain WX-02:

[0021] The shape of the bacteria is rod-shaped, 2-3 microns long and 0.8-1 microns wide. The strain grows on solid medium, and the colony morphology can change: when growing on LB solid medium, the surface of the colony is rough, the edges are wrinkled, and the shape is irregular; when the LB medium contains 2% L-sodium glutamate, The surface of the colony is smooth, the colony is round, regular in shape, and can be drawn in the form of emulsion.

[0022] 2. Physiological and biochemical characteristics of strain WX-02:

[0023] The results...

Embodiment 2

[0043] Example 2 Improvement of poly-γ-glutamic acid production by potassium ion-mediated osmotic pressure

[0044] (1) The original bacterial classification that present embodiment adopts is the same as embodiment 1 (1).

[0045] (2) Activation of strains on inclined planes is the same as in Example 1 (2).

[0046] (3) Seed liquid cultivation is the same as in Example 1 (3).

[0047] (4) Shake flask fermentation culture is the same as in Example 1 (4).

[0048] (5) Osmotic pressure mediated by potassium ions:

[0049] At the 0th hour of fermentation, 5% potassium chloride was added to the fermentation medium and fermented for 48 hours.

[0050] (6) The detection of poly-γ-glutamic acid is the same as in Example 1 (6).

[0051] Taking the treatment without applying osmotic pressure as the control, the output comparison of the two groups after the fermentation is finished is shown in Table 3:

[0052] Table 3. The effect of potassium chloride-mediated osmotic pressure on t...

Embodiment 3

[0055] Example 3 Improvement of poly-γ-glutamic acid production by potassium ion-mediated osmotic pressure

[0056] (1) The original strain is the same as in Example 1 (1).

[0057] (2) Activation of strains on inclined planes is the same as in Example 1 (2).

[0058] (3) Seed liquid cultivation is the same as in Example 1 (3).

[0059] (4) Shake flask fermentation culture is the same as in Example 1 (4).

[0060] (5) Osmotic shock mediated by potassium ions:

[0061] At the 0th hour of fermentation, 3% potassium chloride was added to the fermentation medium and fermented for 48 hours.

[0062] (6) The detection of poly-γ-glutamic acid is the same as in Example 1 (6).

[0063] Taking the treatment without applying osmotic pressure as a control, the output comparison of the two groups after the fermentation is finished is shown in Table 4:

[0064] Table 4. The effect of potassium chloride-mediated osmotic pressure on the fermentation of poly-γ-glutamic acid

[0065] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com