Remover liquid composition and method for removing resin layer by using the same

A technology of composition and stripping liquid, which is applied to the photoplate making process of patterned surface, equipment, electrical components, etc., can solve the problems of metal wiring corrosion and insufficient stripping effect, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

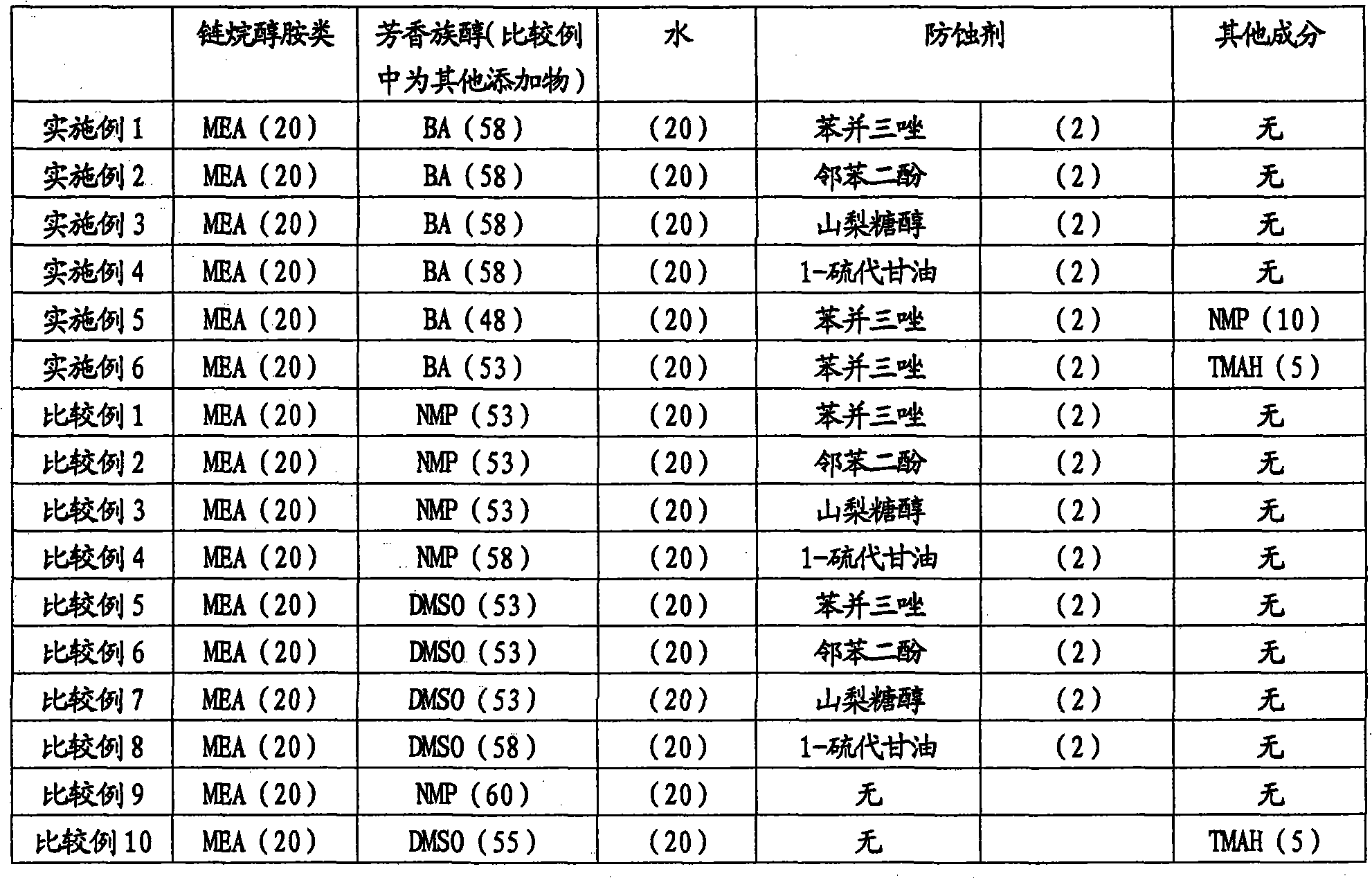

Embodiment 1~6、 comparative example 1~10

[0086] A stripping liquid composition was prepared with the composition shown in Table 1, and a stripping test and a corrosion test were performed. It should be noted that MEA in the table means monoethanolamine, MIPA means monoisopropanolamine, TEA means triethanolamine, BA means benzyl alcohol, FA means phenethyl alcohol, NMP means N-methylpyrrolidone, DMSO means dimethyl sulfoxide , TMAH means tetramethylammonium hydroxide. In addition, the figure in parentheses is the mass % with respect to the whole peeling liquid composition.

[0087] [Table 1]

[0088]

[0089] Table 2 shows the evaluation results.

[0090] [Table 2]

[0091]

[0092]

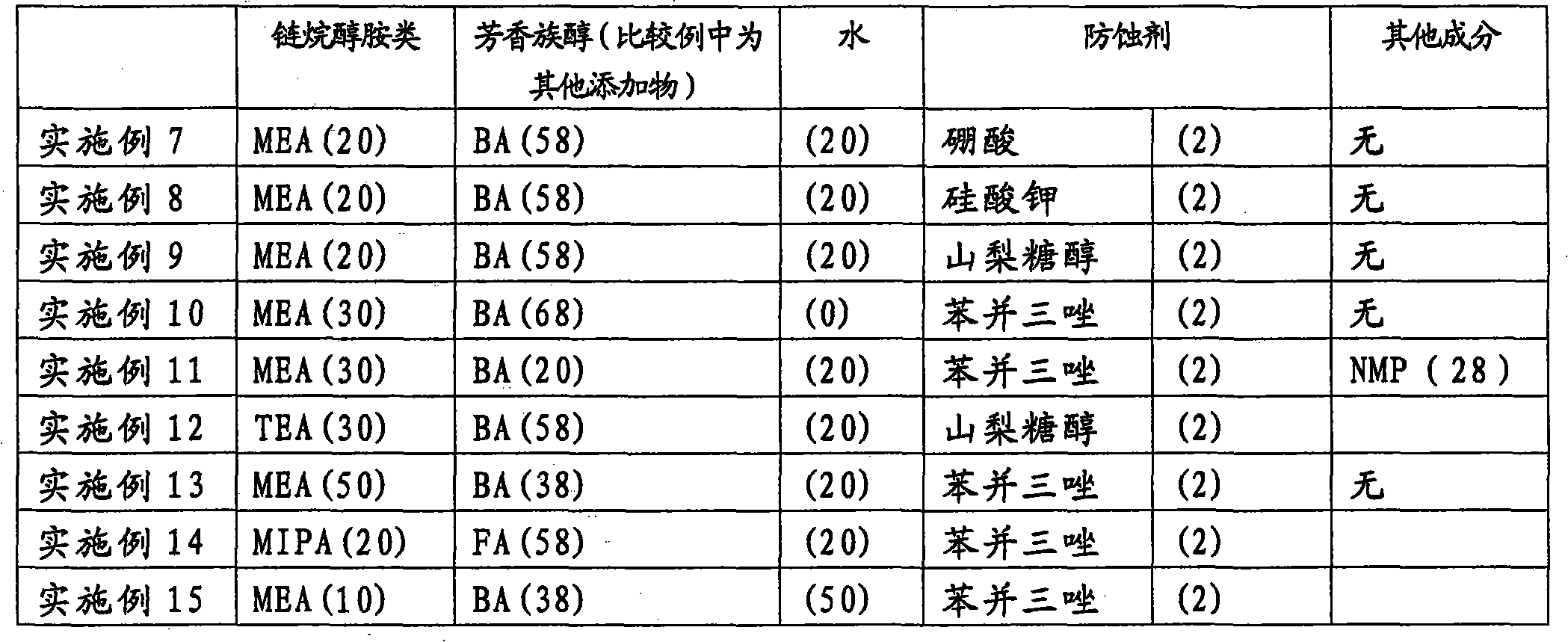

Embodiment 7~15

[0094] Except having prepared the stripping liquid composition with the composition shown in Table 3, the stripping liquid composition was produced similarly to Example 1, and the stripping test and the corrosion test were performed. Table 4 shows the evaluation results.

[0095] [table 3]

[0096]

[0097] [Table 4]

[0098]

[0099]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com