Preparation method and application of Schiff base functionalized ordered mesoporous PMO material solid supported Cu(I) heterogeneous catalyst

A heterogeneous catalyst and functionalization technology, applied in the preparation of organic compounds, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve metal ion pollution in water, difficult separation and recovery Utilization, limited industrial application prospects, etc., to achieve the effect of easy uniform dispersion, large specific surface area, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

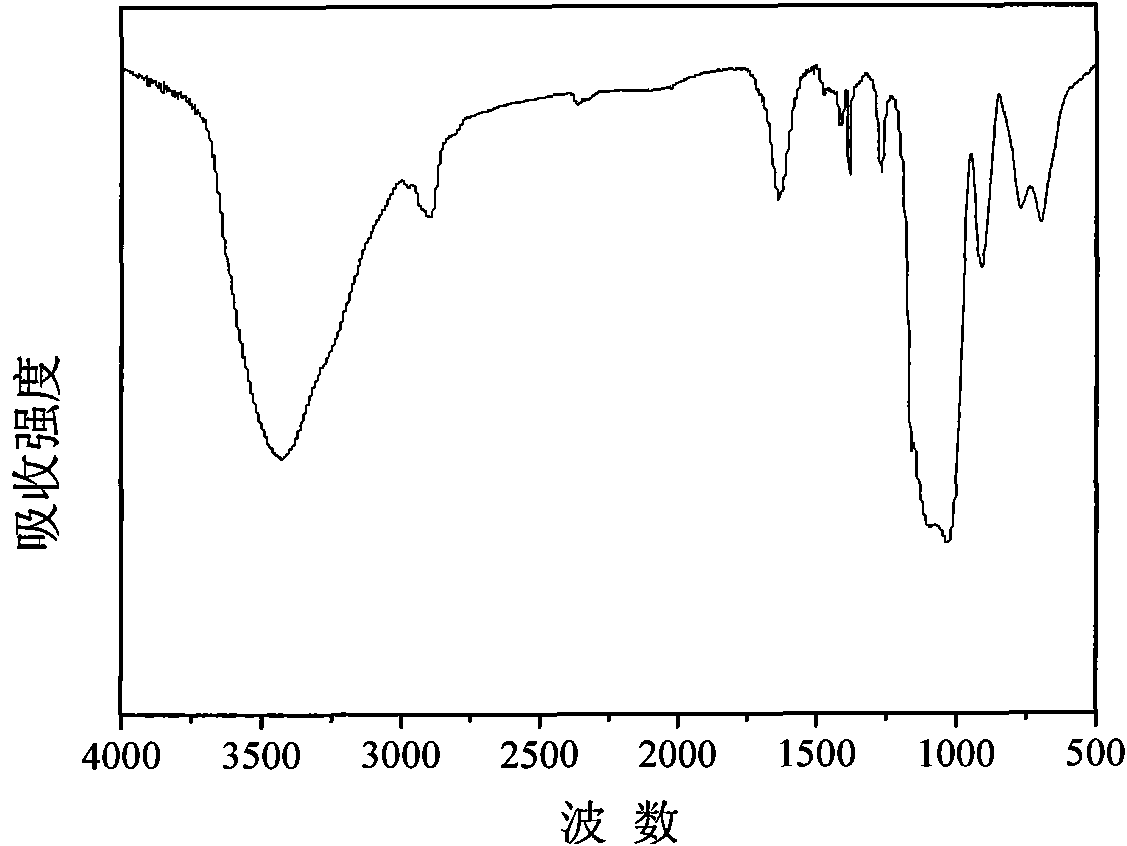

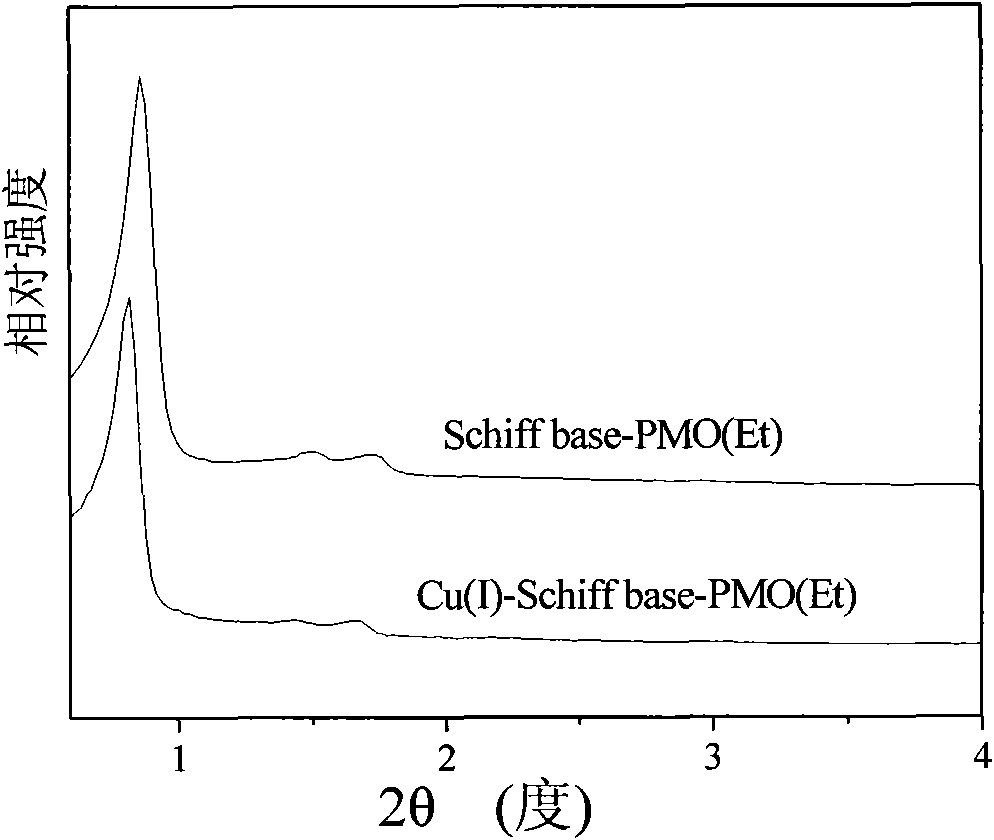

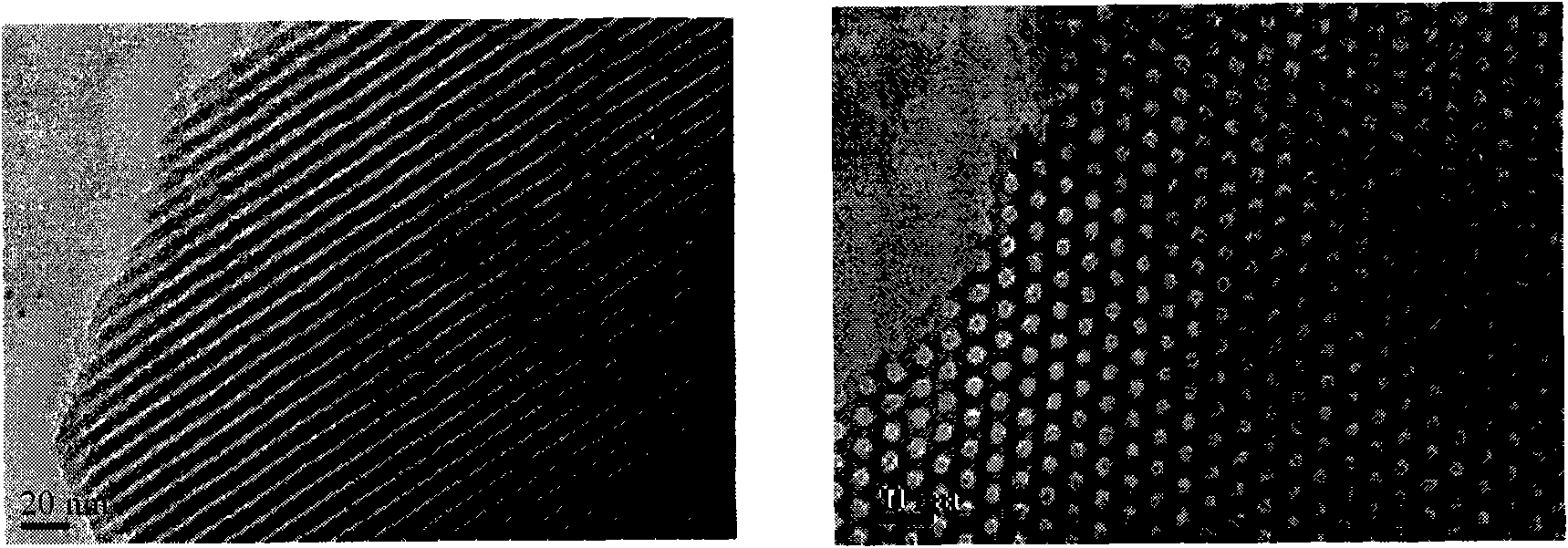

[0027] At room temperature, 1.0 g of amino functionalized ordered mesoporous material PMO(NH 2 -PMO(Et)) (containing N 1.0mmol) was mixed with 10mmol 2-pyridinecarbaldehyde and 20ml ethanol, stirred at room temperature for 15h, then the mixture was filtered, washed, and vacuum-dried overnight at 80°C to obtain ordered mesoporous Schiff base-functionalized PMO(Et) (Schiff base-PMO(Et)). Then take 0.50g Schiffbase-PMO (Et) and add it to 15ml of dimethyl sulfoxide solution containing 0.25mmol CuI (the ratio of Cu and N in the Schiff base functionalized material is 1:2), at room temperature, after stirring for 30h , the solid was filtered and washed with DMSO, ethanol to remove free Cu(I). Finally, the product was dried overnight in a vacuum oven at 80° C. to obtain an ordered mesoporous organometallic copper catalyst.

Embodiment 2

[0029] At room temperature, 0.90 g of amino functionalized ordered mesoporous material PMO(NH 2 -PMO(Et)) (containing N 0.90mmol) was mixed with 0.90mmol 2-pyridinecarbaldehyde and 18ml ethanol, stirred at room temperature for 15h, then the mixture was suction filtered, washed, and dried overnight at 70°C in vacuum to obtain an ordered mediated Schiff base-functionalized PMO(Et) (Schiff base-PMO(Et)). Then take 0.50g Schiffbase-PMO (Et) and add it to 16ml of dimethyl sulfoxide solution containing 0.23mmol CuI (the ratio of Cu and N in the Schiff base functionalized material is 1:2), at room temperature, after stirring for 30h , the solid was filtered and washed with DMSO, ethanol to remove free Cu(I). Finally, the product was dried overnight in a vacuum oven at 80° C. to obtain an ordered mesoporous organometallic copper catalyst.

Embodiment 3

[0031] At room temperature, 1.1 g of amino functionalized ordered mesoporous material PMO(NH 2 -PMO(Et)) (containing N 0.80mmol) was mixed with 0.80mmol 2-pyridinecarbaldehyde and 20ml ethanol, stirred at room temperature for 15h, then the mixture was suction filtered, washed, and vacuum-dried at 80°C overnight to obtain an ordered mediated Schiff base-functionalized PMO(Et) (Schiff base-PMO(Et)). Then take 0.60g Schiffbase-PMO (Et) and add it to 13ml of dimethyl sulfoxide solution containing 0.24mmol CuI (the ratio of Cu and N in the Schiff base functionalized material is 1:2), at room temperature, after stirring for 36h , the solid was filtered and washed with DMSO, ethanol to remove free Cu(I). Finally, the product was dried overnight in a vacuum oven at 80° C. to obtain an ordered mesoporous organometallic copper catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com