Preparation method of beta crystal polypropylene/PET (Polyester) alloy

A polypropylene and polypropylene bonding technology, applied in the chemical industry, can solve the problems of β-crystalline polypropylene thermodynamic instability, reduced content of β-crystalline polypropylene, and reduced β-nucleation, and achieve thermodynamic compatibility, impact Increased strength, improved yield strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

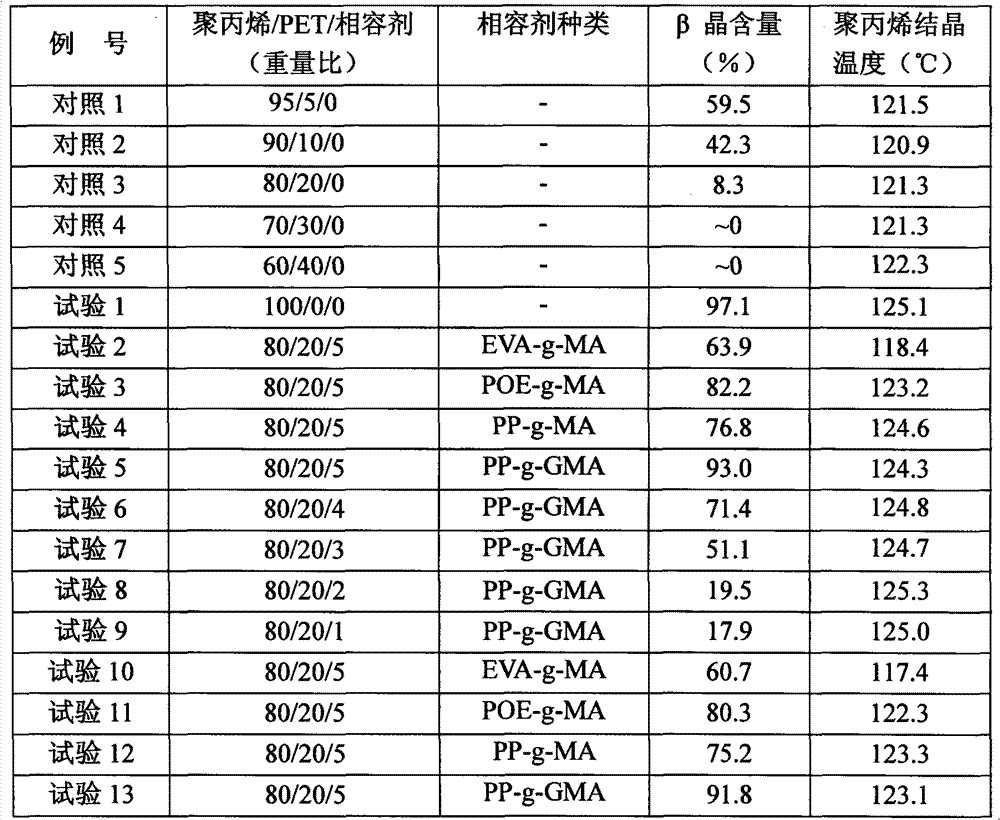

[0026] Beta crystal nucleating agent, polypropylene, PET, compatibilizer (method two) are mixed uniformly at room temperature to become different test groups by the weight ratio shown in test 1-test 9 in table 1; Used β crystal nucleation The agent is a supported β-crystal nucleating agent prepared by nano-calcium carbonate and pimelic acid, and the weight ratio of the β-crystal nucleating agent to polypropylene is 5:100.

[0027] Among them, different types of compatibilizers were added in Test 2 to Test 5 [respectively EVA-g-MA (ethylene-vinyl acetate copolymer grafted maleic anhydride), POE-g-MA (ethylene-octene copolymer grafted maleic anhydride), maleic anhydride), PP-g-MA (polypropylene grafted maleic anhydride), PP-g-GMA (polypropylene grafted glyceryl methacrylate)], test groups 5-9 were added with different contents of PP-g- GMA.

[0028] Each test group was respectively melt-extruded with a twin-screw extruder at 250° C. at a rotational speed of 30 rpm to obtain a β...

Embodiment 2

[0030] β-crystalline polypropylene, PET and compatibilizer (method 1) were uniformly mixed at room temperature according to the weight ratios shown in Test 10-Test 13 in Table 1 to form different test groups.

[0031] Among them, test 10-test 13 added different types of compatibilizers [respectively EVA-g-MA (ethylene-vinyl acetate copolymer grafted maleic anhydride), POE-g-MA (ethylene-octene copolymer grafted maleic anhydride), maleic anhydride), PP-g-MA (polypropylene grafted maleic anhydride), PP-g-GMA (polypropylene grafted glyceryl methacrylate)].

[0032] Each test group was respectively melt-extruded with a twin-screw extruder at 270° C. at a rotational speed of 50 rpm to obtain a β-crystalline polypropylene / PET alloy.

Embodiment 3

[0034] Make 5 groups of contrasts: with β crystal nucleating agent (loaded type β crystal nucleating agent prepared by nano-calcium carbonate and pimelic acid), polypropylene, PET by the weight ratio shown in contrast 1-contrast 5 in table 1 at room temperature Mixed evenly under lower pressure to become different control groups, all without adding compatibilizer, melt extruded with twin-screw extruder at 250°C, rotating speed 30rpm, to obtain β crystal polypropylene / PET alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com