Texture thinning processor for large bearing material

A technology of bearing materials and processing machines, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as poor control and complicated processes, achieve the effect of changing the working environment, reducing the size of carbides, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

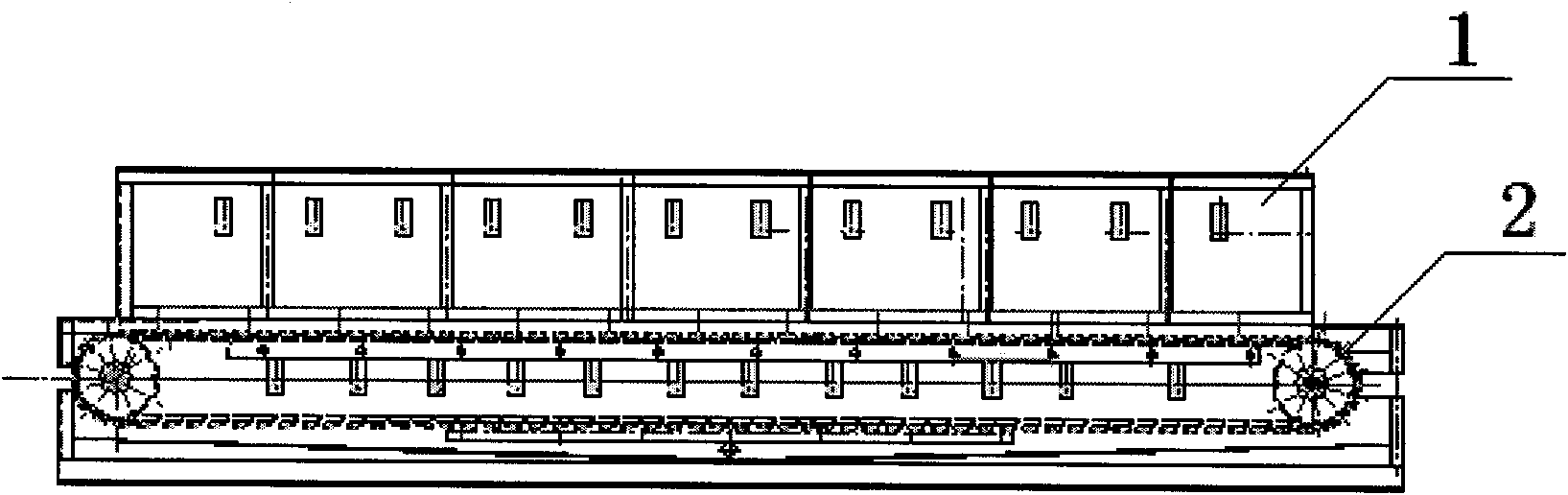

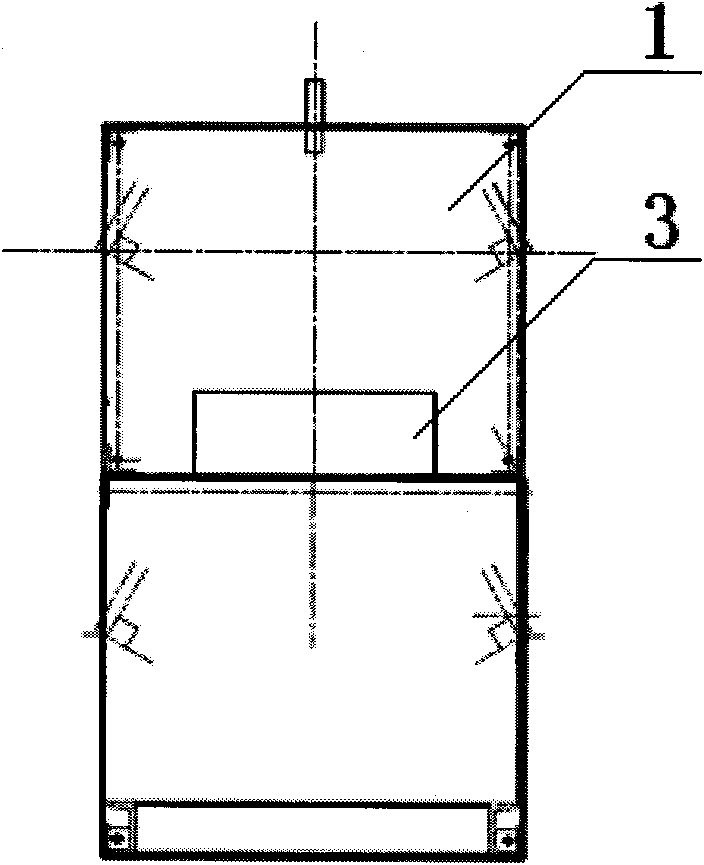

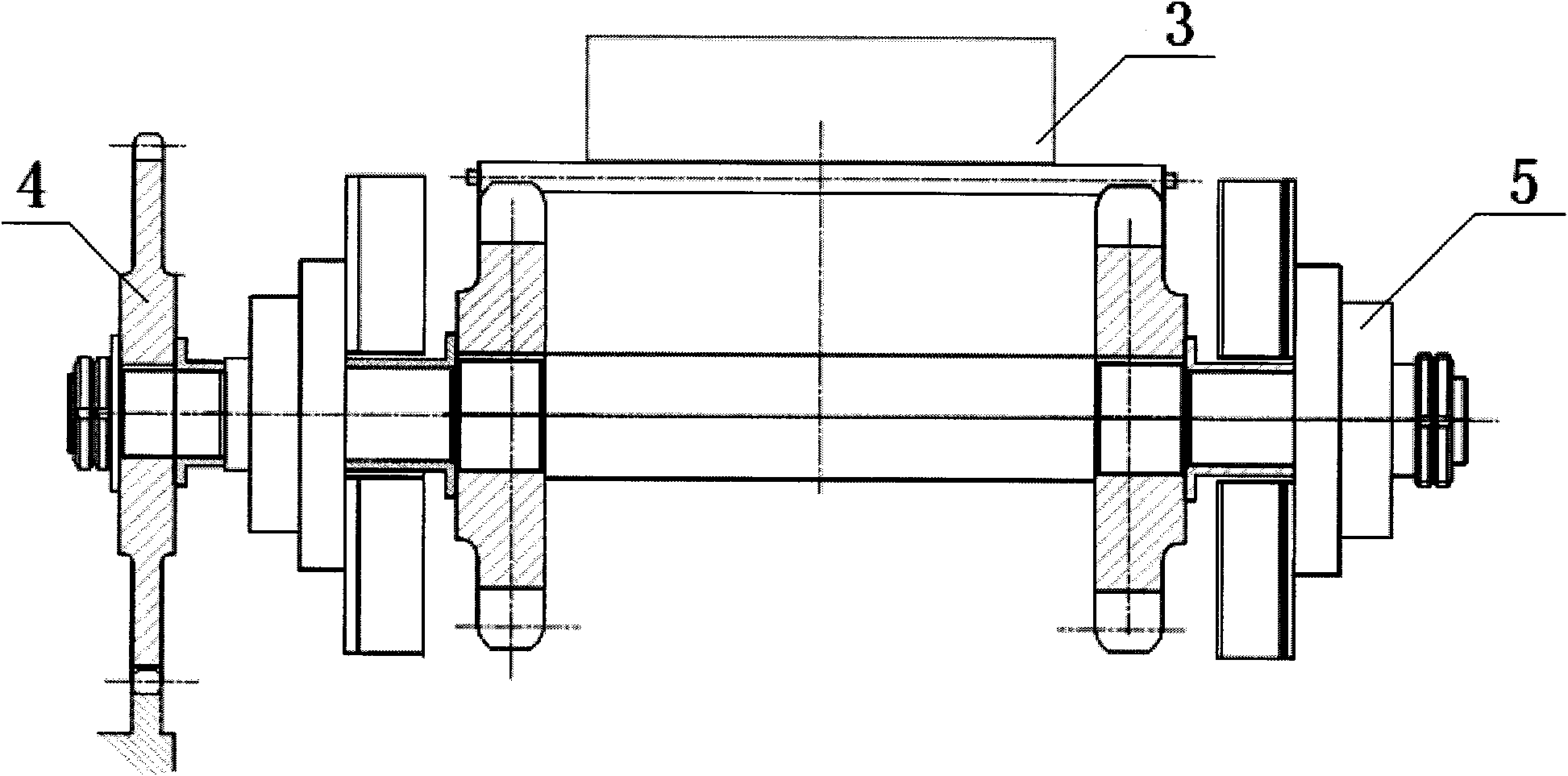

[0013] combine figure 1 , the present embodiment includes a physical and chemical treatment area 1 and a mechanical transmission device 2, the physical and chemical treatment area 1 is arranged above the mechanical transmission device 2, a spray device is arranged in the physical and chemical treatment area 1, and the mechanical transmission device 2 includes a sprocket 5 and a frequency conversion speed regulating device 4. The frequency conversion speed regulating device 4 links the sprocket 5, and the workpiece 3 is placed on the sprocket 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com