Power factor correction converter based on magnetic coupling lossless buffer circuit

A power factor correction and buffer circuit technology, which is applied to output power conversion devices, high-efficiency power electronic conversion, electrical components, etc. The effect of reducing switching loss, improving efficiency, and suppressing reverse recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

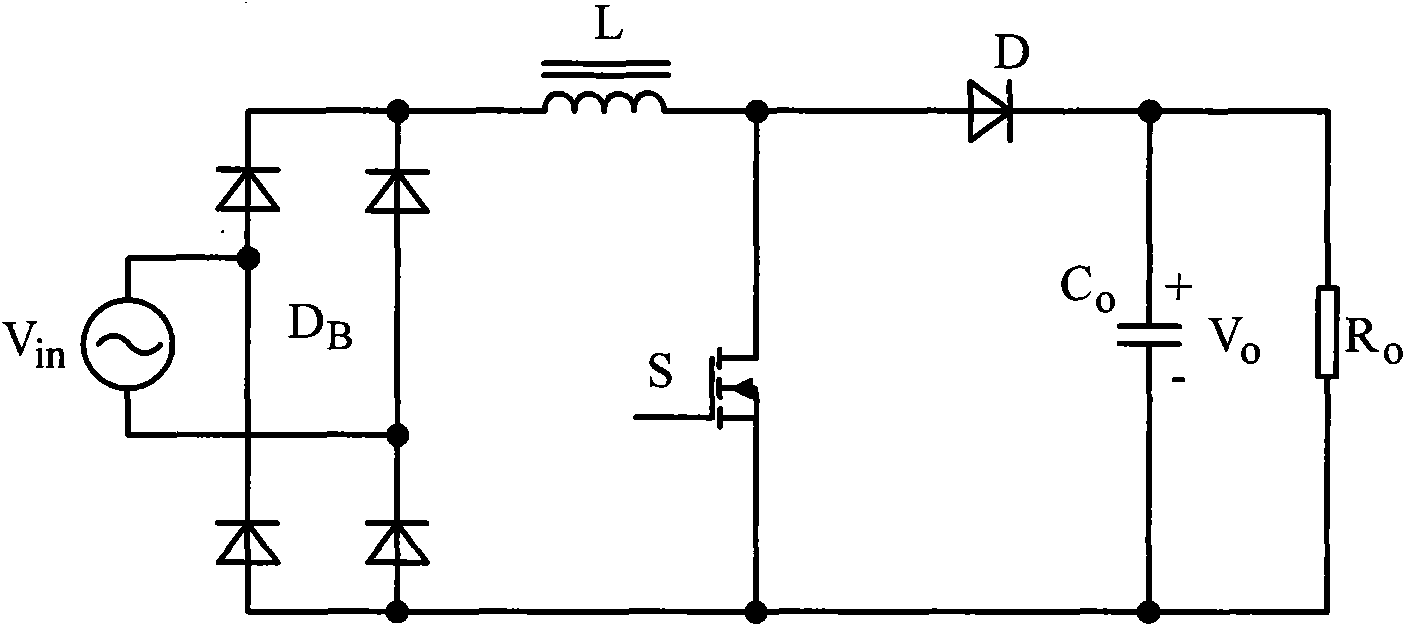

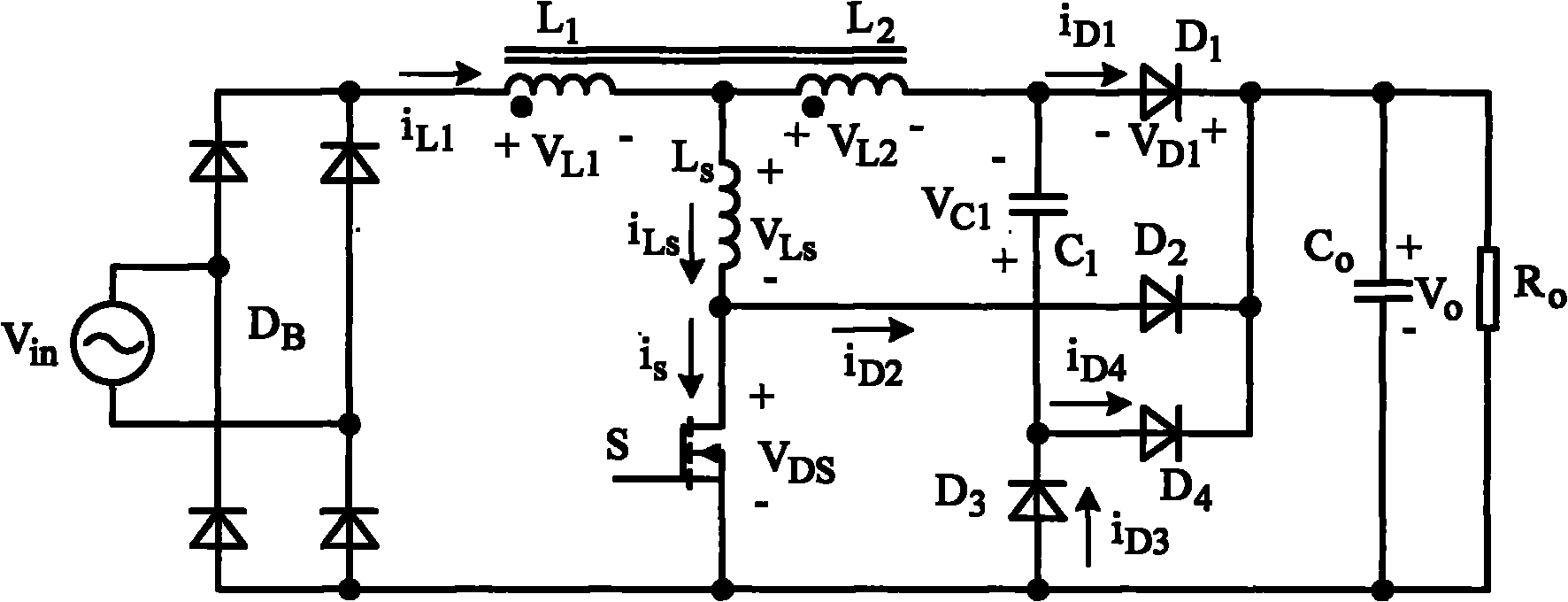

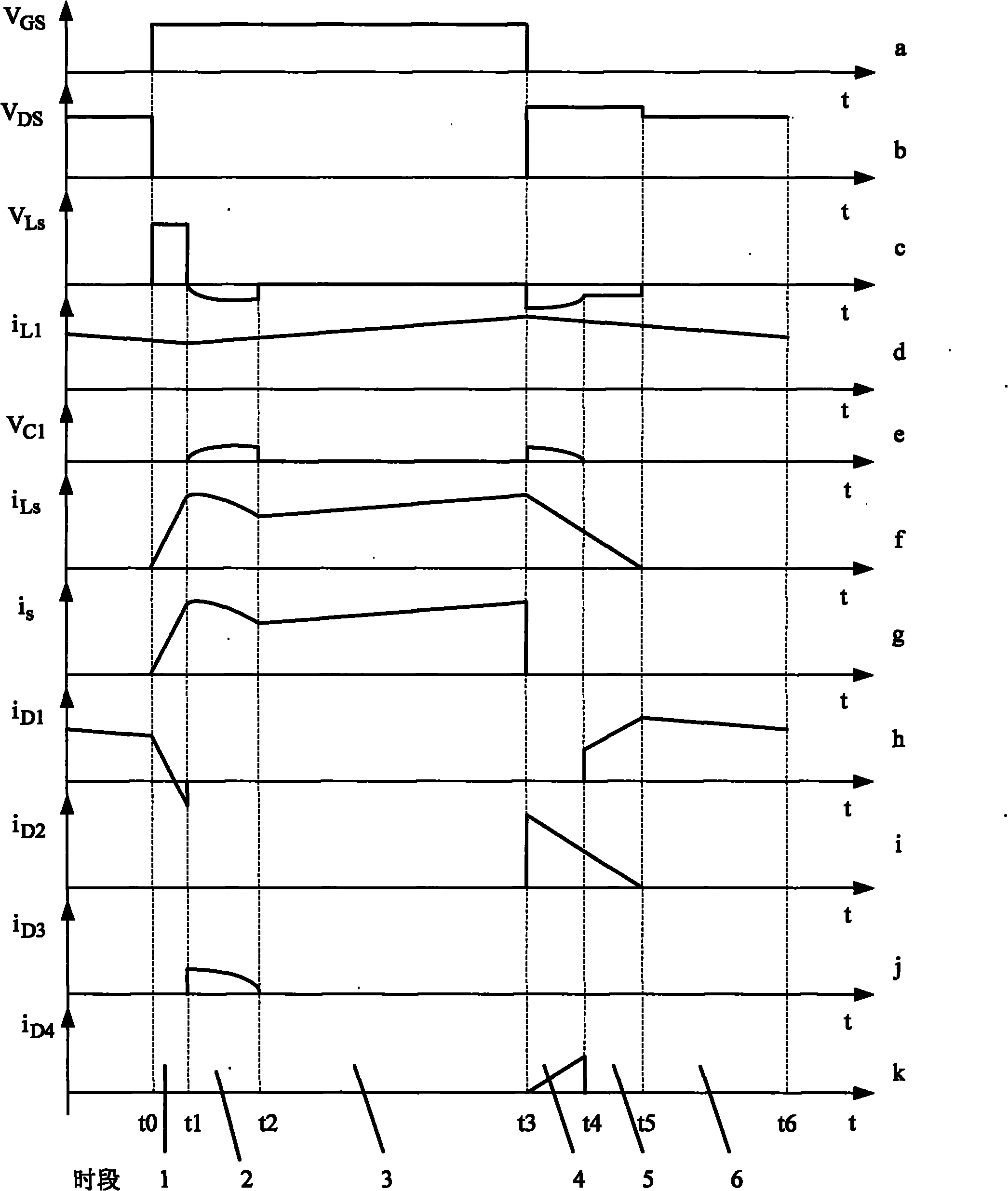

[0012] The inventive circuit such as figure 2 As shown, it includes a diode bridge rectifier circuit and a boost conversion circuit, and the bridge rectifier circuit consists of a rectifier bridge circuit D composed of four diodes B , the boost converter circuit includes an auxiliary coupling winding L with an 2 The boost inductor L 1 , main power switch S, snubber inductor L S , snubber capacitance C 1 , the first diode D 1 , the second diode D 2 , the third diode D 3 , the fourth diode D 4 , the boost inductor L 1 Terminal with the same name and rectifier circuit D B connected to the common cathode terminal, the boost inductor L 1 The non-identical end of the coupling winding L 2 Dotted terminal with snubber inductance L S One end of the snubber inductor L is connected together S The other end of the rectifier circuit D B The main power switch S is connected between the common anode terminals, and the snubber inductor L S The junction with the main power switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com