Method for synchronous precipitation and polymeric synthesis of floatable silver sulfide nanocrystalline

A technology of nanocrystals and silver sulfide, applied in chemical instruments and methods, silver compounds, silver compounds, etc., can solve the problems of large particle size of silver sulfide, easy sinking to the bottom, high cost, etc., to achieve inhibition of agglomeration, improvement of dispersion, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

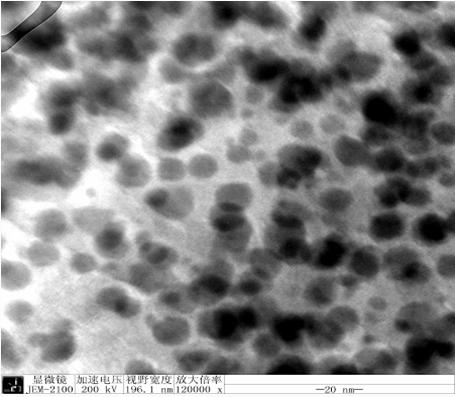

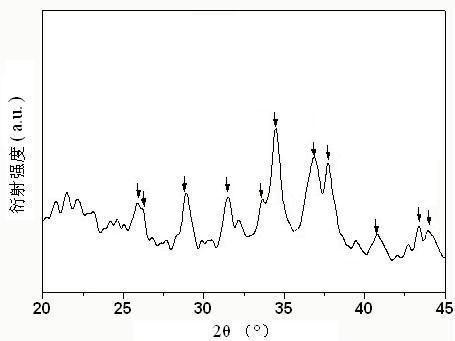

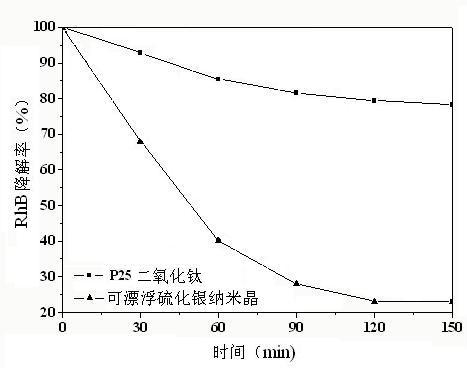

[0007] Specific embodiment one: the synchronous precipitation-polymerization synthesis method of a kind of floatable silver sulfide nanocrystal of the present embodiment is carried out according to the following steps: one, add 24mL~26mL volume concentration by 1g silver nitrate and be the ratio of 95% ethanol, Weigh silver nitrate and ethanol with a volume concentration of 95%, add silver nitrate to ethanol, and then place it in an ultrasonic processor with a frequency of 30kHz to 50kHz for 30min to 50min to obtain a silver nitrate solution; The volume ratio of ethanol in step 1 is 1:1, and the mass ratio of 3-mercaptopropyltrimethoxysilane to silver nitrate in step 1 is 1.4~1.6:1. Weigh toluene and 3-mercaptopropyltrimethoxysilane , then adding toluene to the silver nitrate solution obtained in step 1, stirring for 5-10 minutes, then adding 3-mercaptopropyltrimethoxysilane dropwise, after the dropwise addition, continue stirring for 55-65 minutes to obtain a sol; 3. Add the ...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, add 24.3mL~25.7mL the ratio of ethanol whose volume concentration is 95% by 1g silver nitrate, take silver nitrate and volume concentration is 95% of ethanol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment three: what this embodiment is different from specific embodiment one or two is: in step one, add 25.0mL volume concentration by the ratio of 95% ethanol by 1g silver nitrate, take by weighing silver nitrate and volume concentration be 95% ethanol. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com