A strain of Bacillus subtilis xdk06 and its application

A technology of Bacillus subtilis and microbial strains is applied in the field of microbial application and fertilizer fermentation, which can solve the problems of pollution sources at the bottom of the pond, fertilizer nutrient loss, and equipment being easily damaged by corrosion, so as to improve the effective utilization rate, the environmental protection of the fermentation process, and the reduction of The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

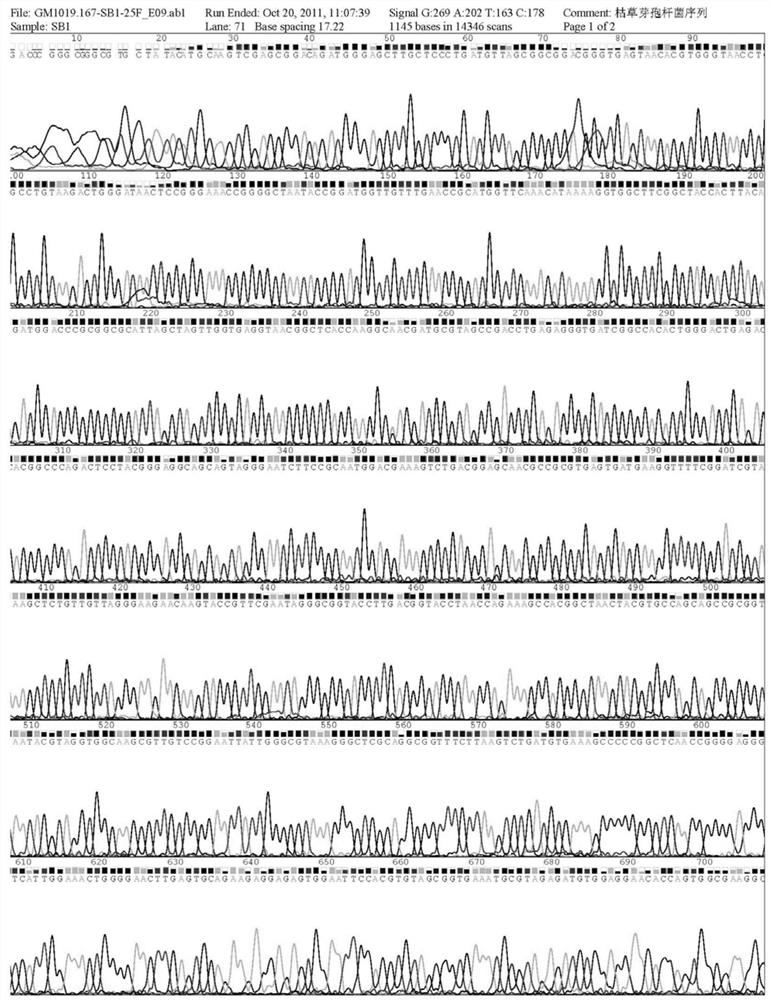

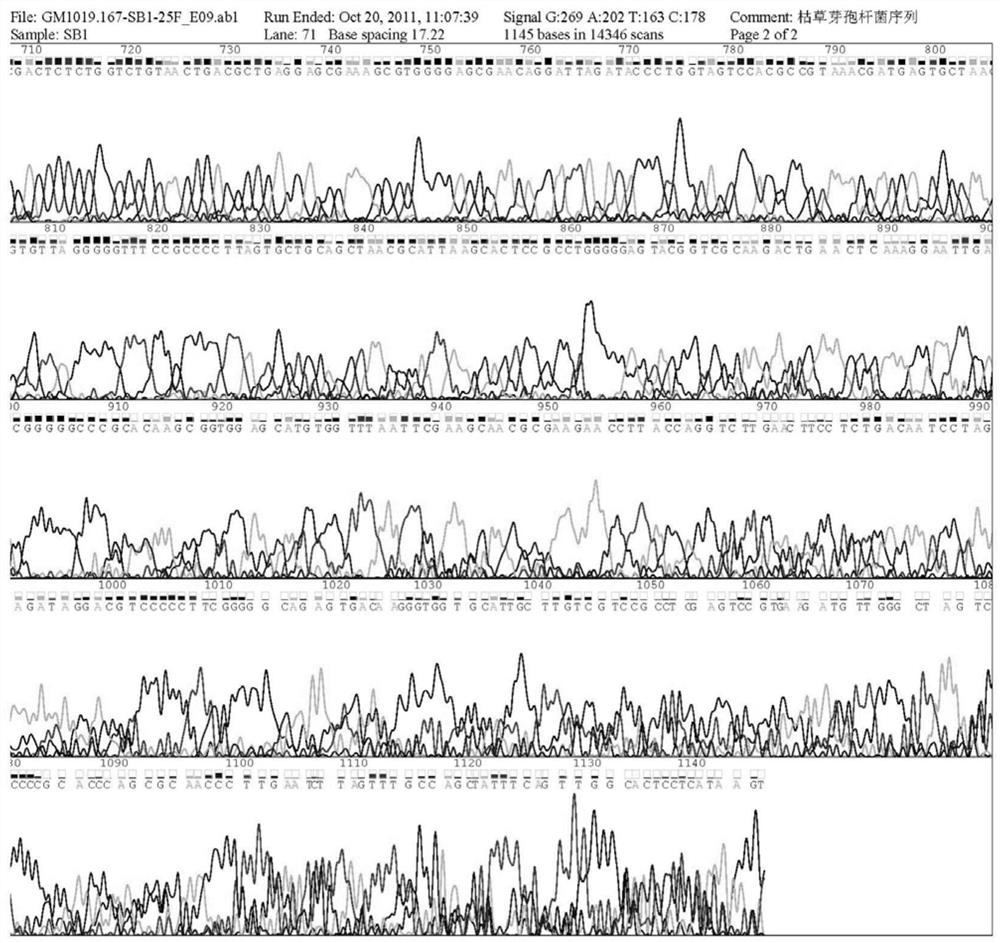

Image

Examples

Embodiment 1

[0029] Example 1 Strain domestication and screening

[0030] (1) Prepare the acclimation medium

[0031] Firstly, the chicken manure, mushroom residue and rice bran are pretreated such as drying, impurity removal and crushing, and then mixed uniformly according to the weight ratio of chicken manure: mushroom residue: rice bran=30~50:20~30:20~30, for use;

[0032] (2) Prepare the strain to be domesticated

[0033] 12 strains of yeast, 16 strains of Bacillus subtilis and 8 strains of Lactobacillus acidophilus were selected as the strains to be domesticated;

[0034] (3) Environmental conditions for domestication

[0035] An anaerobic fermentation environment with a water content of 50% to 60%, a pH of 4.5 to 7.5, and a temperature of 30 to 50°C;

[0036] (4) Domestication process

[0037] Use a 2-liter conical flask, put 1 kg of the above-mentioned acclimation medium, adjust the water content and pH value according to the above-mentioned conditions, and then respectively ins...

Embodiment 2

[0041]A preparation method of organic nutrients is carried out indoors, and the room temperature is between 20 and 25 DEG C. The preparation steps are as follows: chicken manure, mushroom residue and rice bran are evenly mixed in a weight ratio of 50:25:25, and then piled into piles, The weight of each pile is controlled within 100 tons, and then Bacillus subtilis XDK06 is evenly added to obtain an anaerobic fermentation system. The addition amount of Bacillus subtilis XDK06 is 2% of the weight of the organic material. Anaerobic fermentation was carried out for 60 days, the initial water content of the control material was 50%-60%, the pH value of the anaerobic fermentation system was controlled at 4.5-7.5, the fermentation process was turned once every 20 days, and the whole fermentation process was turned twice in total . During the fermentation process, because the fermented raw materials used (ie chicken manure, mushroom residue and rice bran) have undergone pretreatment s...

Embodiment 3

[0043] A preparation method of organic nutrients is carried out indoors, and the room temperature is higher than 25°C. The preparation steps are as follows: the chicken manure and mushroom residue are evenly mixed at a weight ratio of 70:30, and then piled into piles, and the weight of each pile is controlled at 100 Within 1 ton, then evenly add Bacillus subtilis XDK06 to obtain an anaerobic fermentation system, the addition amount of Bacillus subtilis XDK06 is 5% of the weight of the organic material, and the anaerobic fermentation system is anaerobic fermentation at 30 ℃ ~ 50 ℃ for 20 days, control The initial water content of the material is 50%-60%, the pH value of the anaerobic fermentation system is controlled at 4.5-7.5, and the heap is turned once on the 10th day of fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com