Preparation method of capillary probe array used for analyzing biochips

A biochip and probe array technology, applied in the field of capillary probe array preparation, can solve the problems of high processing cost, slow production speed, expensive precision instruments, etc., and achieve the goal of accelerating production speed, reducing processing cost, and reducing dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

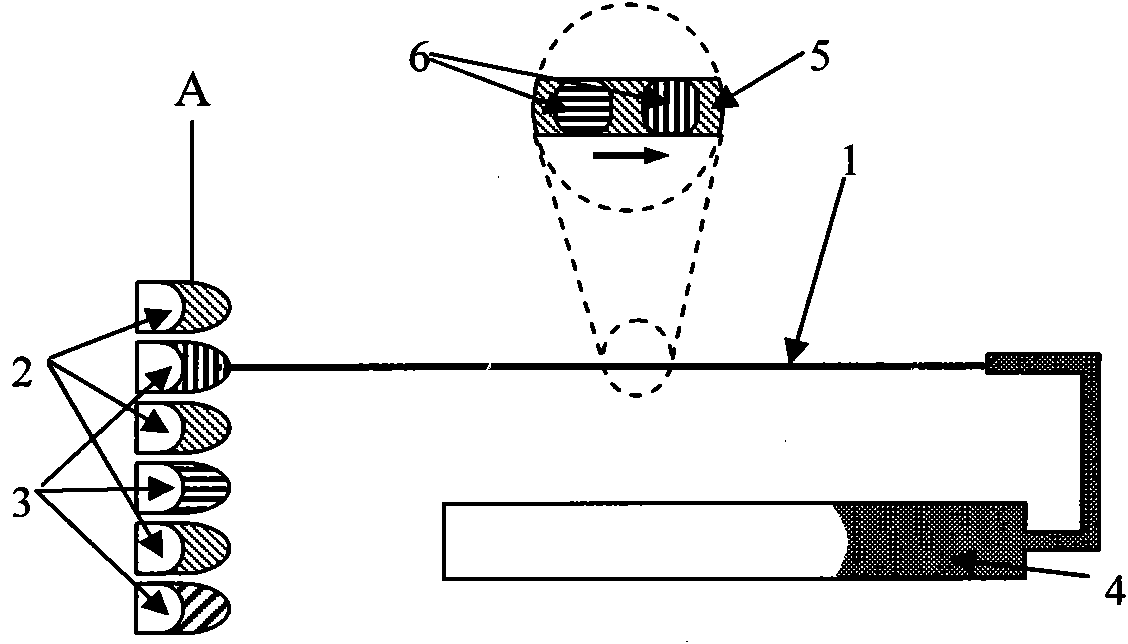

[0019] see figure 1 , the inlet of the capillary 1 is inserted into a small liquid storage test tube A, and the small liquid storage test tubes A are arranged at intervals and are respectively equipped with mineral oil 2 and probe solution 3 . The outlet of the capillary 1 is connected to a horizontal liquid storage tank 4 , and gravity is used to drive the liquid to flow, so that the carrier current 5 carries the droplet sequence 6 to flow in the capillary 1 . After the flow reaches the predetermined position, the flow is stopped and the immobilization reaction of the probe is carried out to complete the processing of the biochip.

[0020] Figure 4 It is the fluorescent signal intensity obtained by fixing nucleic acid probes of different concentrations for 30 minutes. The probe contains 20 bases, 3' labeled with FITC, 5' labeled with amino groups, through chemical reactions with free aldehyde groups modified on the capillary wall and is fixed in the capillary.

Embodiment 2

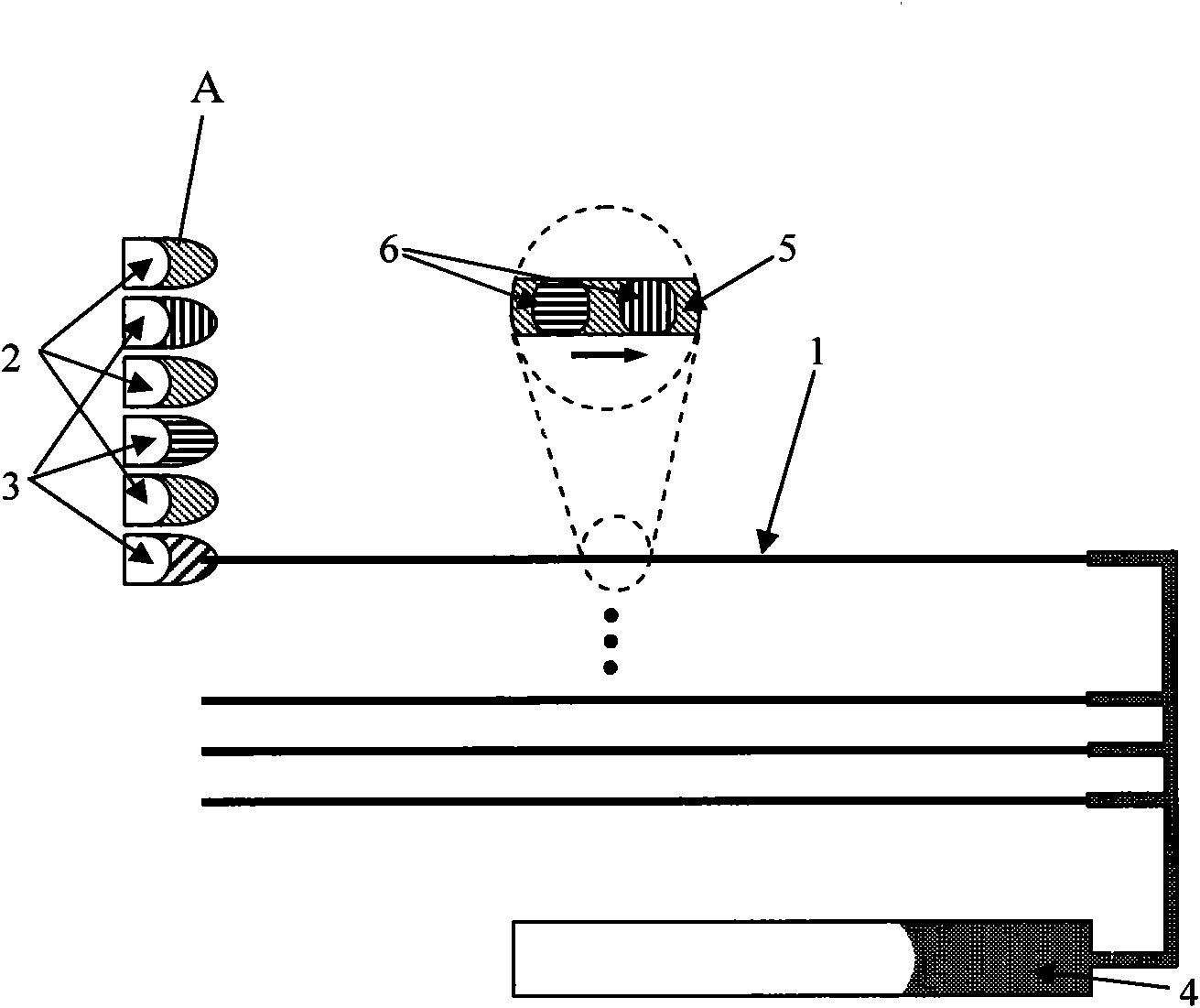

[0022] see figure 2 , the capillary 1 is a plurality of parallel capillaries, each channel has an inlet and an outlet, and a plurality of parallel probe arrays are processed for analysis of a plurality of parallel biochips. exist figure 2 , each tag is associated with figure 1 same.

Embodiment 3

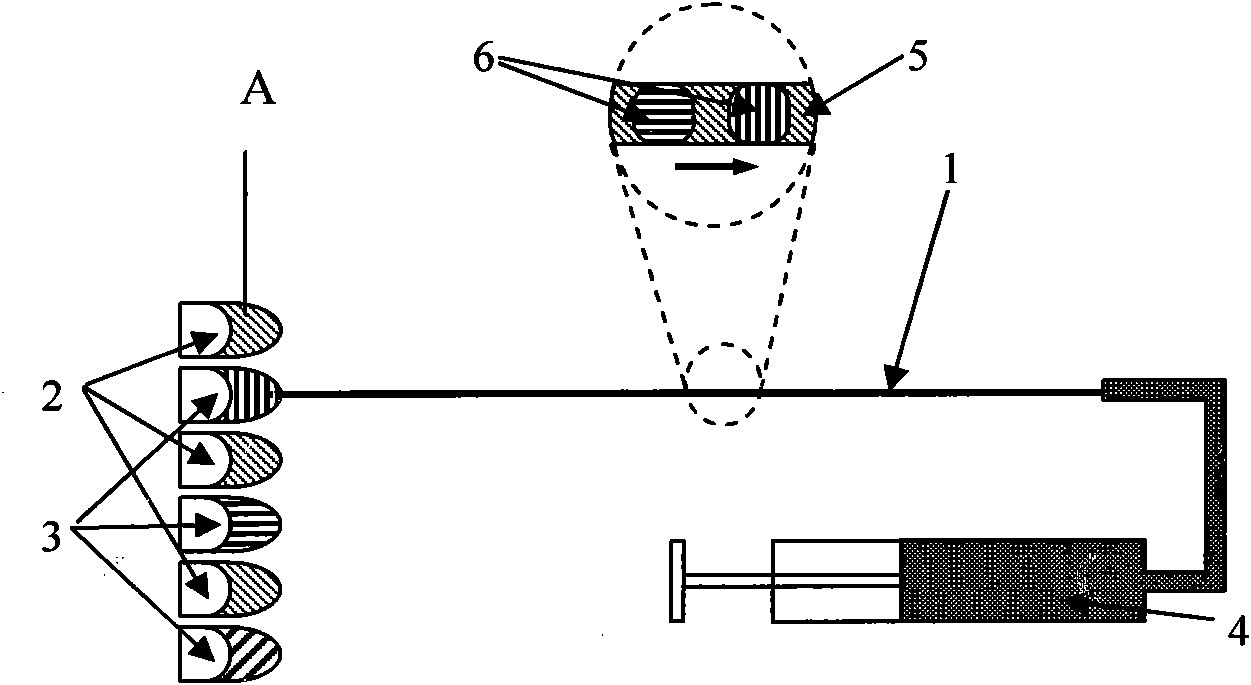

[0024] see image 3 , the outlet of the capillary 1 is connected with a syringe, and the negative pressure generated by the syringe drives the flow of the liquid. exist image 3 , each tag is associated with figure 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com