External medicinal composition for treating skin ulcer and preparation method thereof

A technology for external use of drugs and skin ulcers, which is applied in the field of medicine and can solve problems such as clinical application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

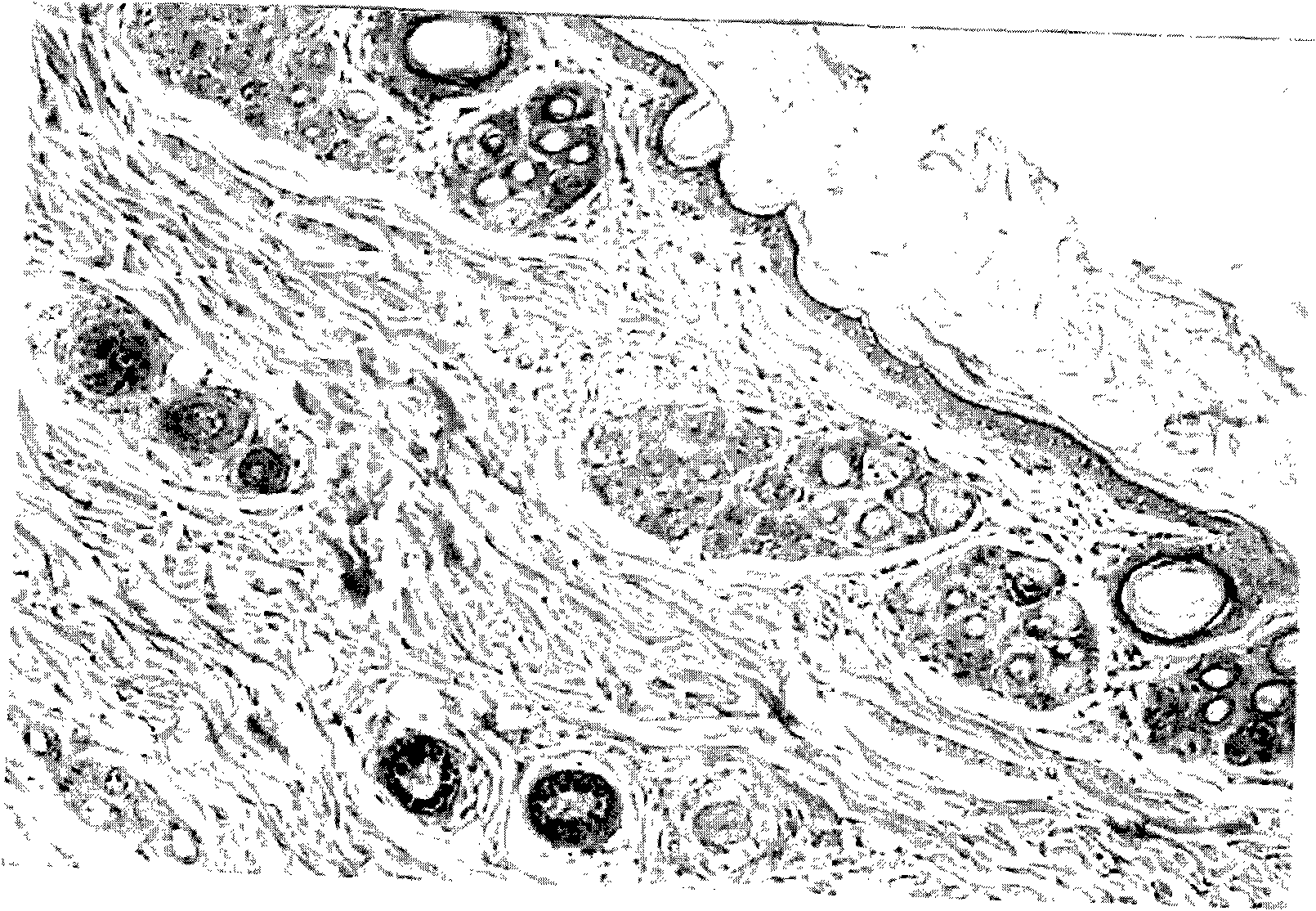

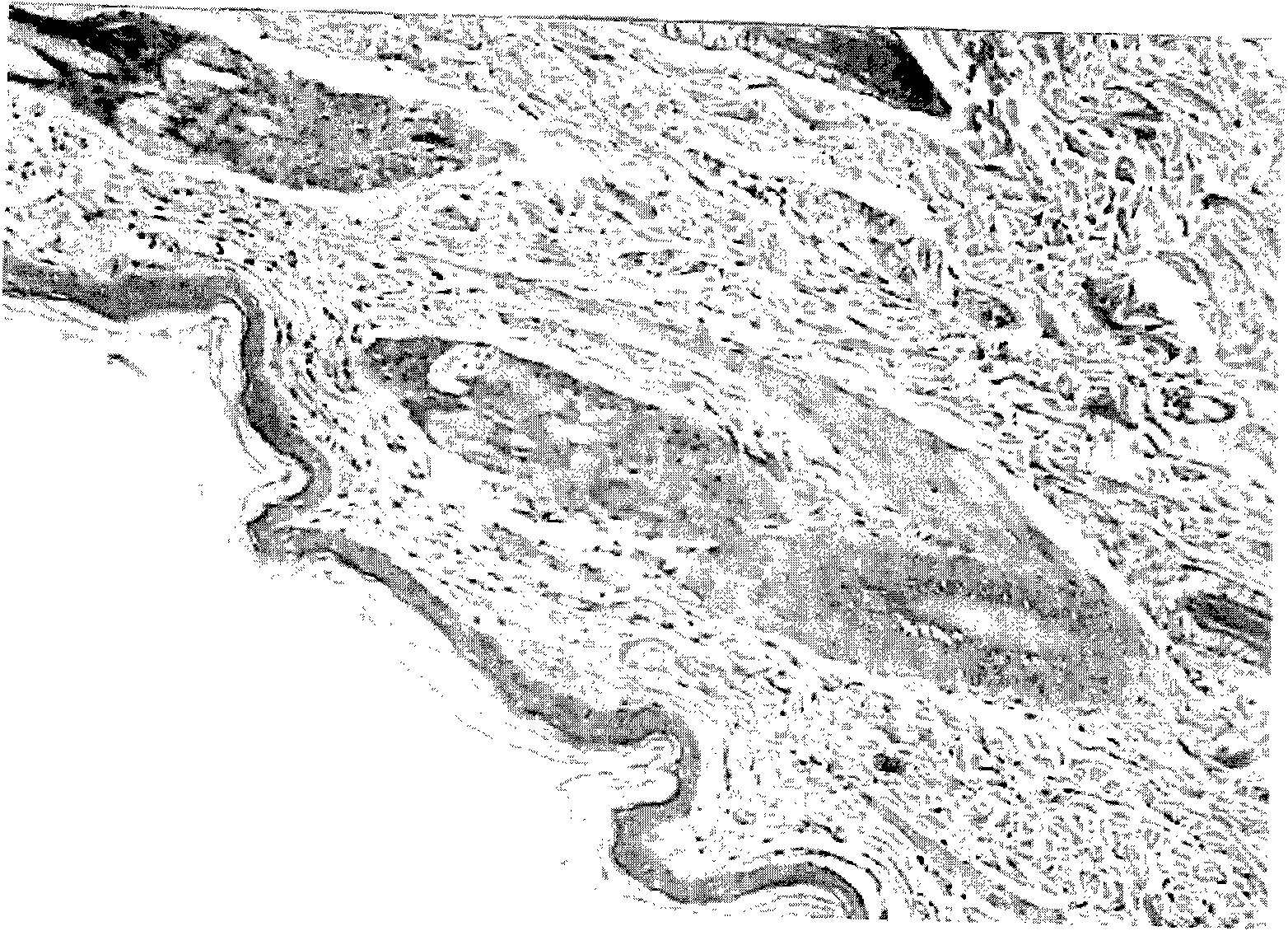

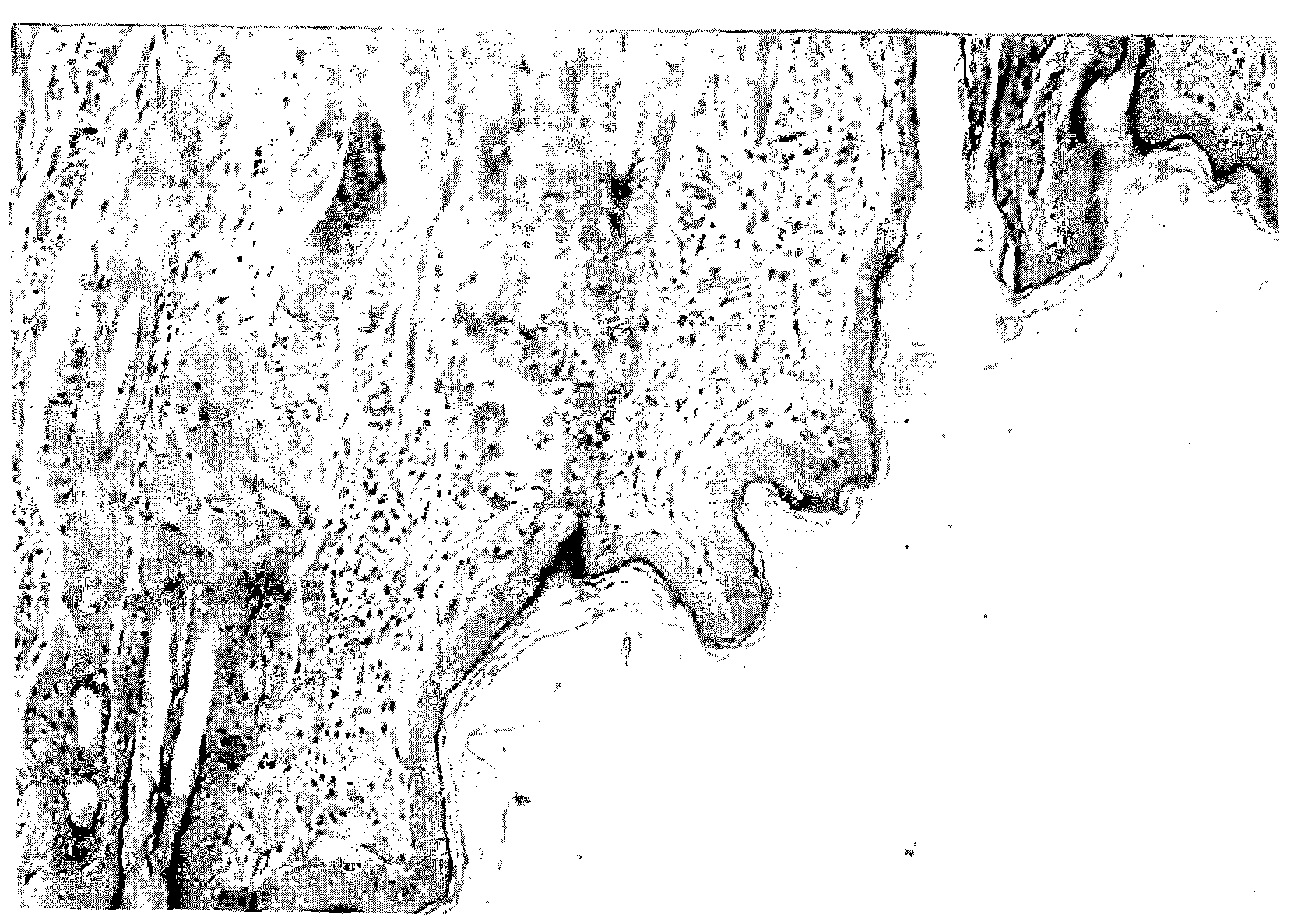

Image

Examples

Embodiment 1

[0162] Example 1 Preparation of refined white sugar

[0163] 1. The proportion of raw and auxiliary materials:

[0164] White sugar: deionized water: activated carbon: ethanol=15:15:0.45:15 (mass ratio W / W)

[0165] 2. Preparation process

[0166] (1) Weigh 1500g white sugar, 1500g deionized water, 45g activated carbon, and 1500g ethanol for use;

[0167] (2) Put the weighed sugar into the tank, add the weighed deionized water, stir and heat 80-85℃ to dissolve;

[0168] (3) Add the weighed activated carbon, decolorize for 20-30 minutes, and filter while it is hot;

[0169] (4) Concentrate under reduced pressure at 50-95°C until the sugar content in the white sugar concentrate is 80%-85%;

[0170] (5) When the temperature is lowered to 50-70°C, slowly add the weighed ethanol;

[0171] (6) Continue to cool down to 20-25°C, stir and crystallize for 3-4 hours;

[0172] (7) Centrifugal crystallized refined sugar;

[0173] (8) Dry it at 105-110℃ for 3-4 hours;

[0174] (9) Qualified inspection; pack...

Embodiment 2

[0175] Example 2 Preparation of compound refined white sugar ointment

[0176] 1. The proportion of raw and auxiliary materials:

[0177] Refined white sugar: neomycin sulfate: citric acid and sodium hydroxide buffer (pH 4.2): poloxamer: glycerol: polyethylene glycol 400: sodium alginate = 70:3:18:1:1:1:3 : 0.3 (mass ratio W / W)

[0178] 2. Preparation process

[0179] (1) Weigh 180g of citric acid and sodium hydroxide buffer (pH 4.2), 700g of refined sugar, 30g of neomycin sulfate, 10g of poloxamer, 10g of glycerin, 30g of polyethylene glycol 400, and 3g of sodium alginate ,spare;

[0180] (2) Put the weighed refined white sugar into the tank, add citric acid and sodium hydroxide buffer (pH 4.2), turn on the stirring and raise the temperature until it is completely dissolved, continue to heat up to 120-122°C for heat preservation, and keep it for 15- 20 minutes; then after cooling down to 80-90℃, keep warm for use;

[0181] (3) Put the weighed polyethylene glycol 400, glycerin, poloxa...

Embodiment 3

[0184] Example 3 Preparation of compound refined white sugar powder

[0185] 1. The proportion of raw and auxiliary materials:

[0186] Refined white sugar: kanamycin sulfate: hydroxypropyl cellulose=70:3:27 (mass ratio W / W)

[0187] 2. Preparation process

[0188] (1) Take 700 g of refined white sugar and 270 g of hydroxypropyl cellulose in a prescription amount, mix, crush, and pass through a 325 mesh medicinal sieve;

[0189] (2) Weigh 30g of kanamycin sulfate in proportion to the prescription and reserve;

[0190] (3) Put the weighed kanamycin sulfate into the sieved (1), and mix in the mixer;

[0191] (4) Packaging, inspection and storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com