Process for manufacturing copper or iron ore series of noble metal commemorative coins or medals and dies used thereby

A production process and commemorative coin technology, applied to medals, badges, coins, etc., can solve the problems of difficult to guarantee the quality of mold relief, low production cost, insufficient embossed patterns on products, etc., to achieve unique appearance, low production cost, product quality Stable quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The content of the present invention is described in detail through the examples, but not limited by the examples.

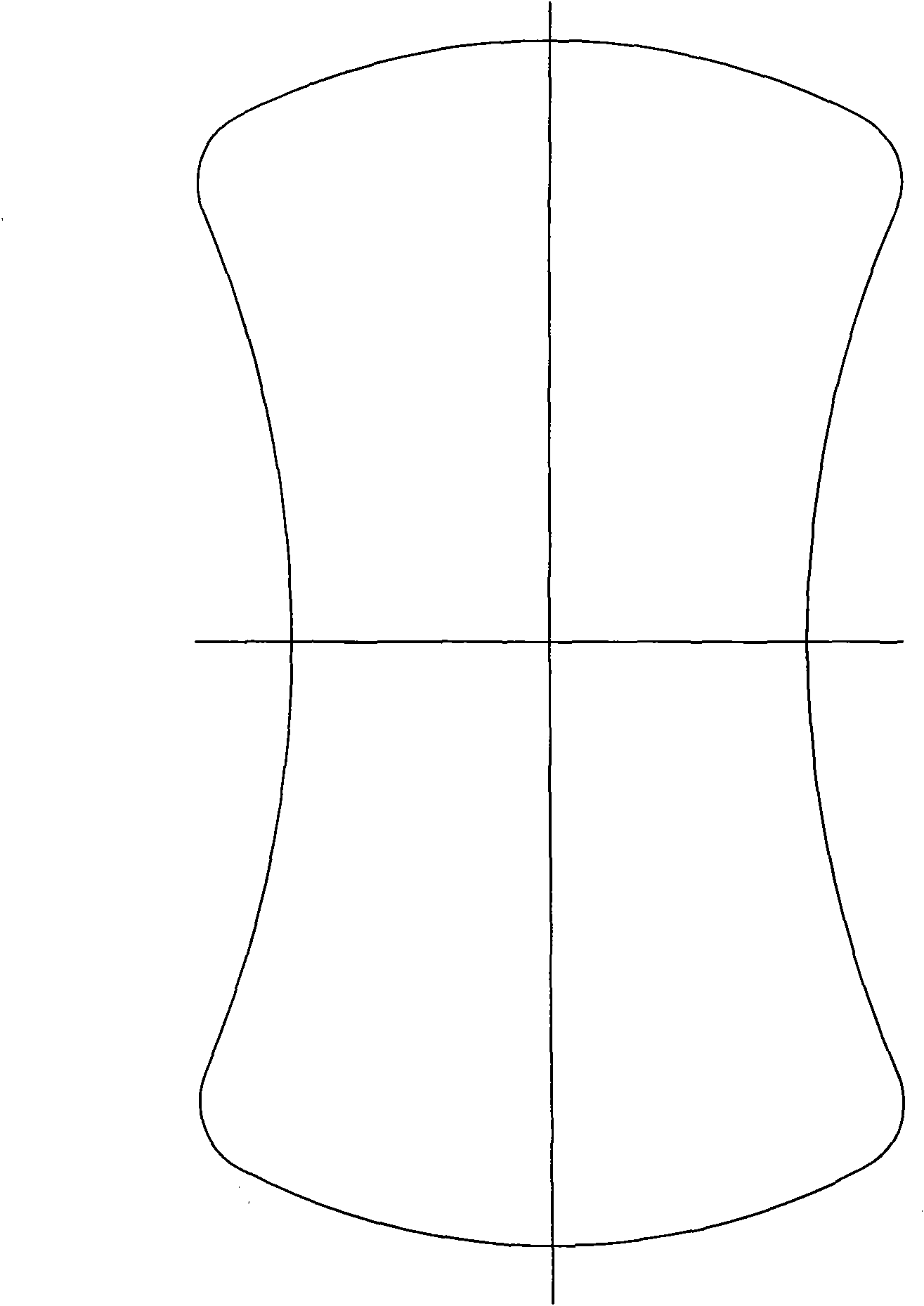

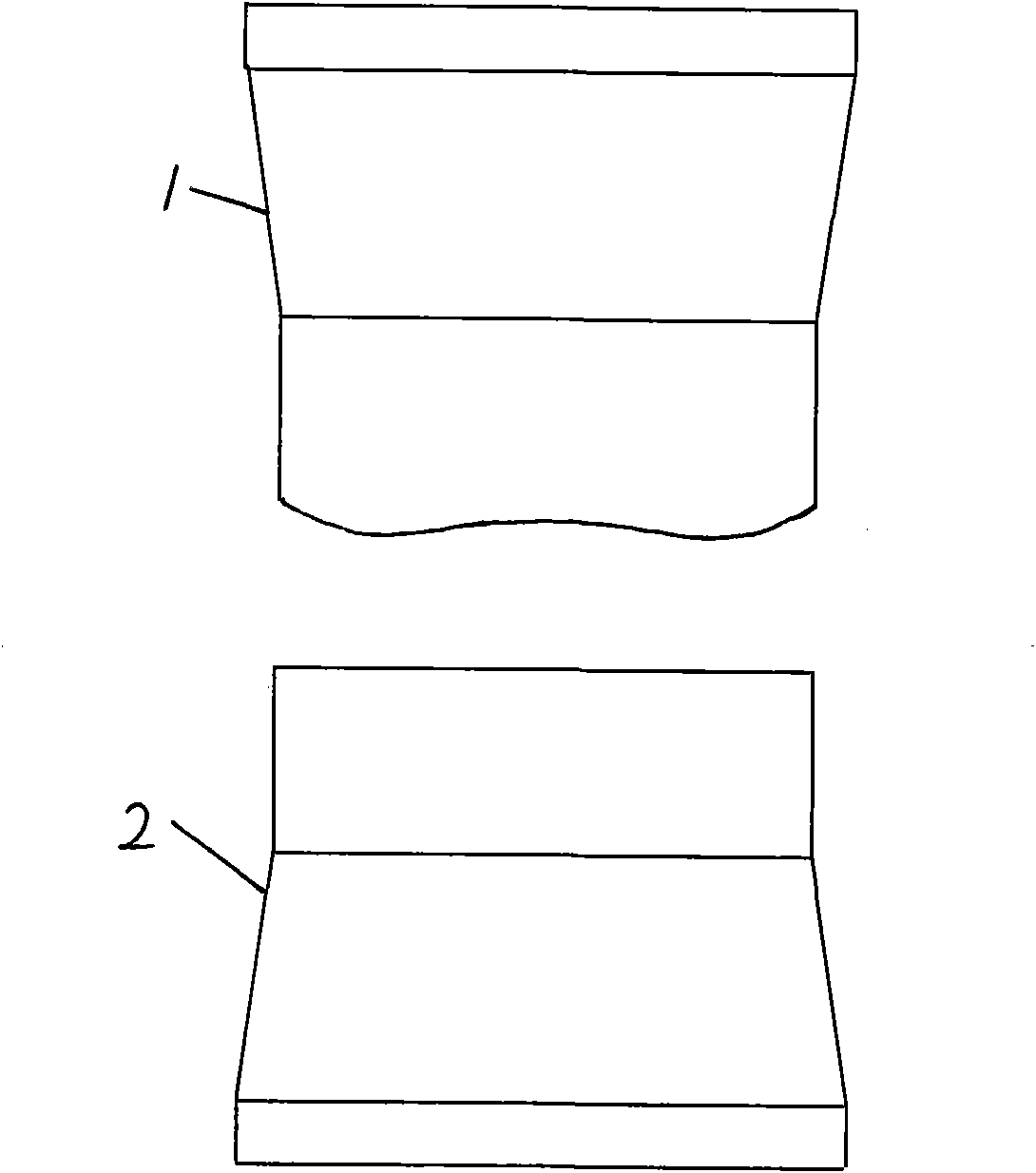

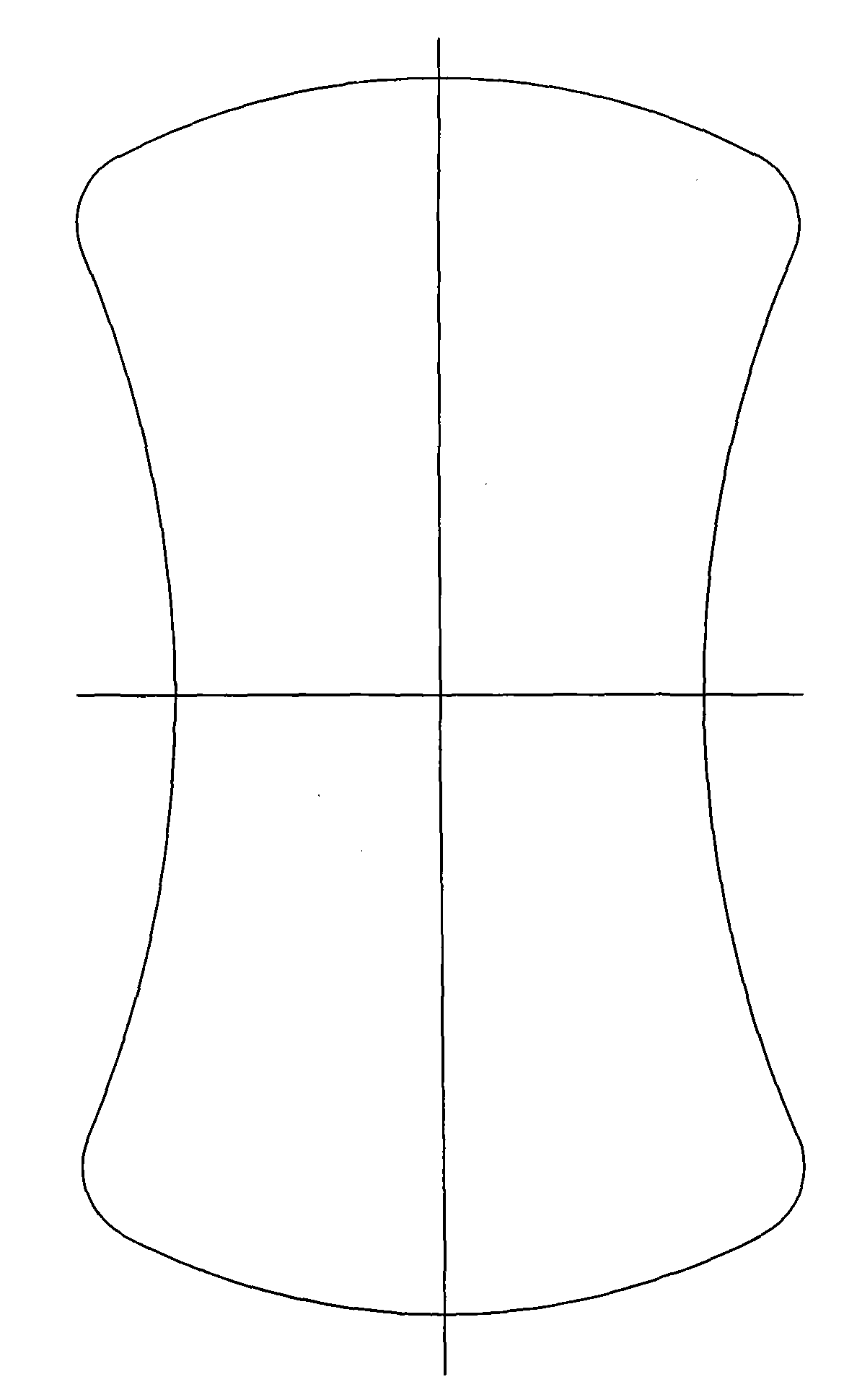

[0025] The method of the present invention takes the preparation of 100g silver collar as an example, its external dimension is 60mm * 35, the waist width is 25.64mm, the long direction arc radius is 33.23mm, the width direction arc radius is 54.64mm, and the corner transition arc radius is 3.70mm. First select the designed length and width parameters, and use the three-dimensional relief design software to design and generate the radius of the arc in the length and width directions, as well as the radius of the transition arc connecting the length and width directions, to form the two-dimensional plane outline of the 100g silver collar curve. Then look for the waist section curve respectively (see curve structure figure 2 ), select a circle with a diameter of 0.05mm at the center of the collar and the contour line as the driving line, and at the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com