Ternary microwave medium material of Li2O-CoO2-TiO2 and low temperature sintering method

A microwave dielectric material, V2O5 technology, applied in the field of microwave dielectric ceramics, can solve problems such as Ag melting, and achieve the effect of simple chemical composition and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

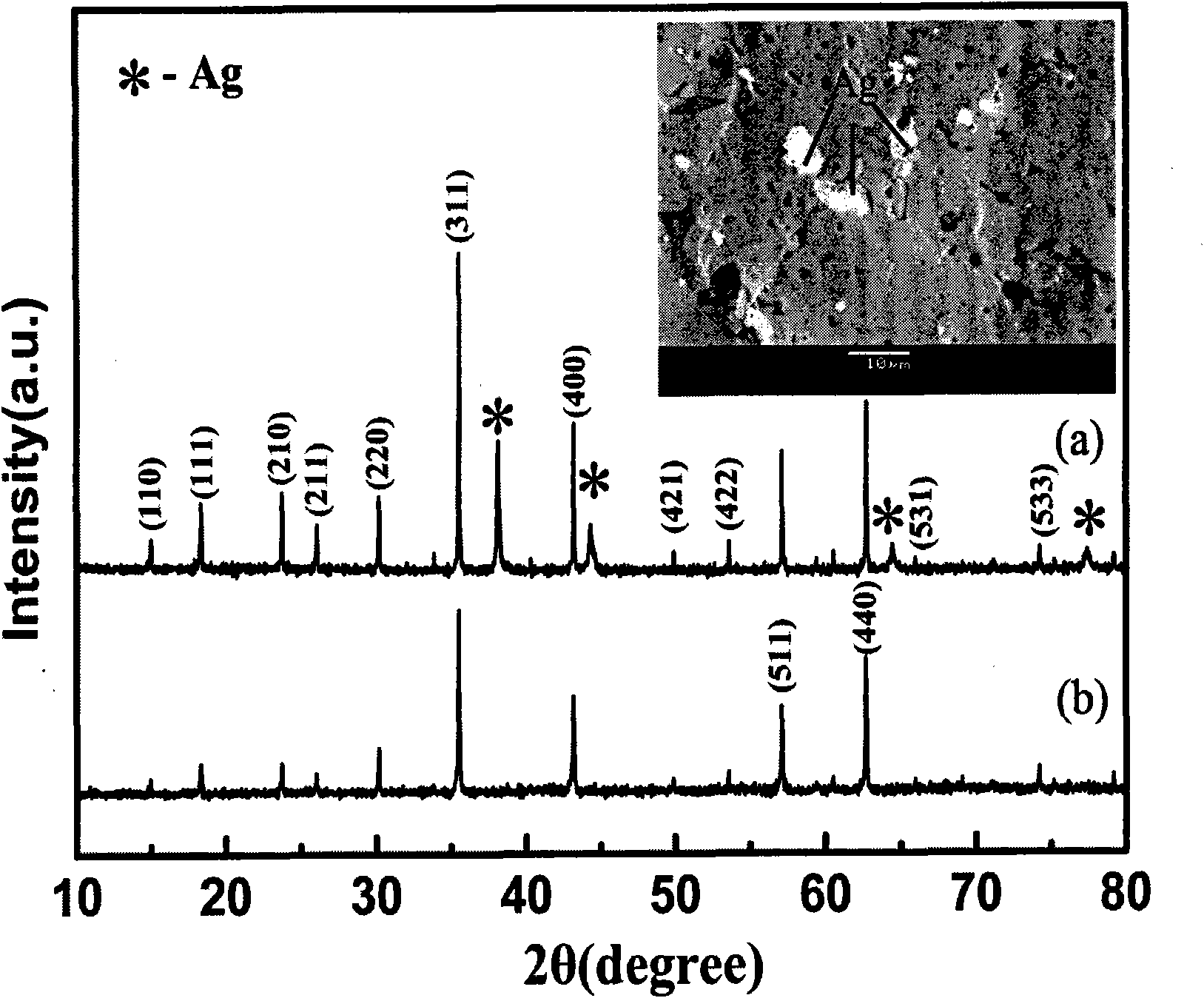

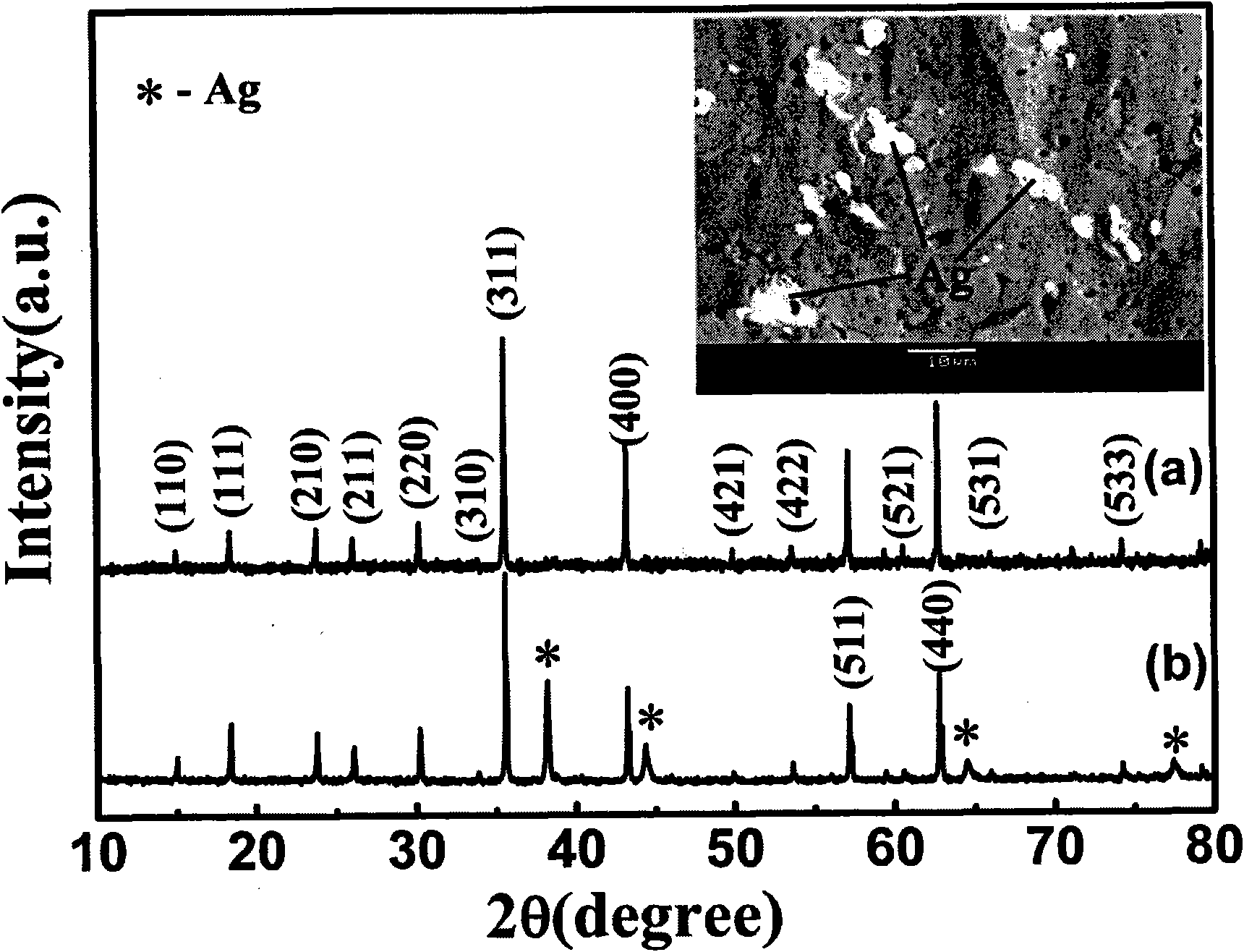

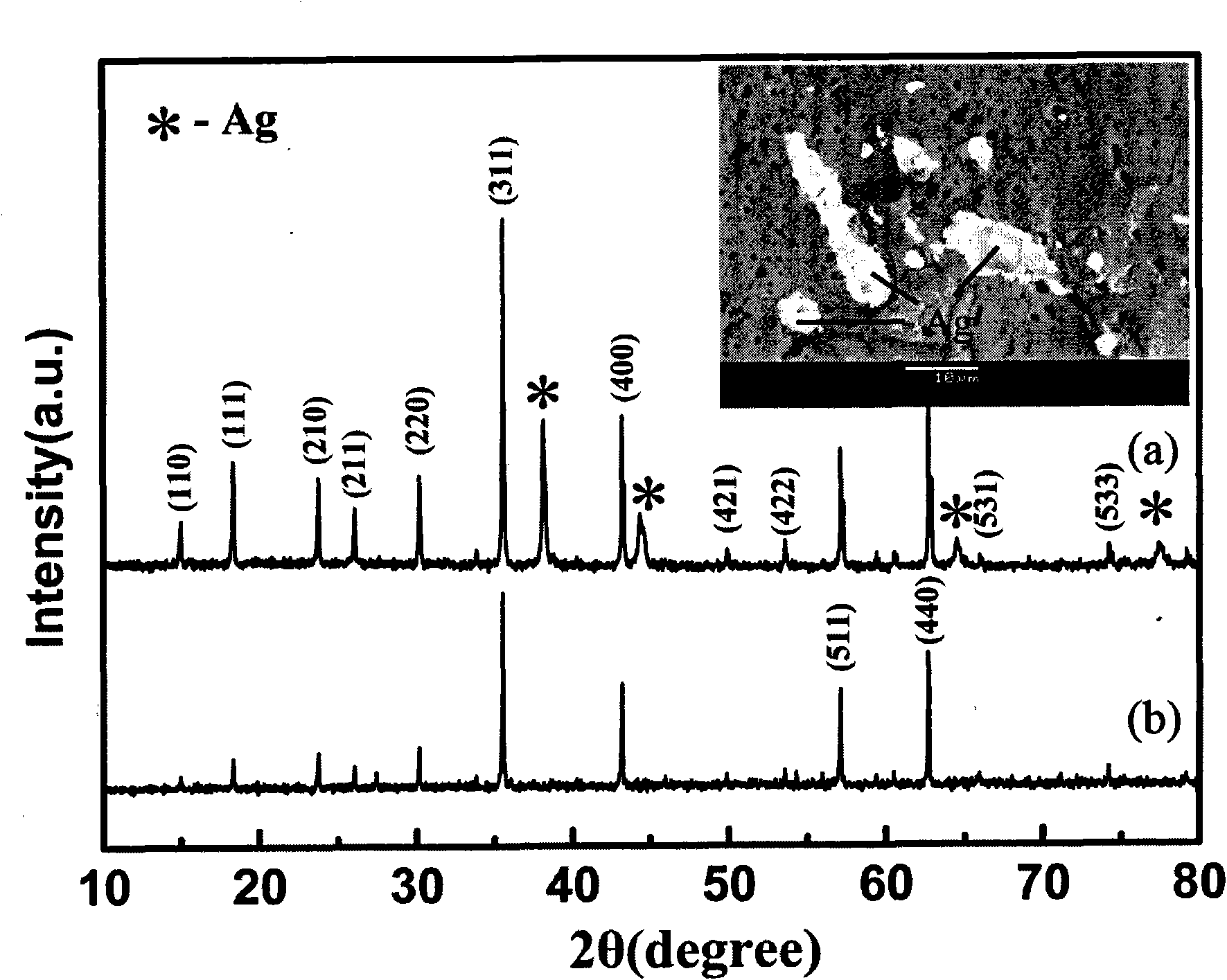

Image

Examples

Embodiment 1

[0022] 1) First, more than 99.9% of the analytically pure raw material Li 2 CO 3 、Co 2 o 3 and TiO 2 Moore Billy 2 CO 3 :Co 2 o 3 :TiO 2 = 2:1:6 to prepare the main powder;

[0023] 2) Prepare the obtained powder from step (1) by wet ball milling for 12 hours. The solvent is distilled water. After drying, it is pre-fired in the atmosphere at 900°C for 4 hours, and then the pre-fired powder is crushed, and 1% by weight % low melting point substance H 3 BO 3 .

[0024] 3) Mix the product obtained in step (2) by wet ball milling for 12 hours. The solvent is distilled water. After drying, add a binder and granulate it, then press and shape it, remove the glue at 550°C, and finally dry it in the atmosphere at 850°C Sintering for 2 hours; the binder uses a polyvinyl alcohol aqueous solution with a mass concentration of 5%, and its dose accounts for 6% of the total mass of the main powder obtained in step (1), so that a low-temperature sintered LTCC microwave dielectric cer...

Embodiment 2

[0026] 1) First, more than 99.9% of the analytically pure raw material Li 2 CO 3 、Co 2 o 3 and TiO 2 Moore Billy 2 CO 3 :Co 2 o 3 :TiO 2 = 2:1:6 to prepare the main powder;

[0027] 2) Prepare the obtained powder from step (1) by wet ball milling for 12 hours. The solvent is distilled water. After drying, it is pre-fired in the atmosphere at 900°C for 4 hours, and then the pre-fired powder is crushed, and 1% by weight % low melting point substance H 3 BO 3 .

[0028] 3) Mix the product obtained in step (2) by wet ball milling for 12 hours. The solvent is distilled water. After drying, add a binder and granulate, then press and shape, debinding at 550°C, and finally in an atmosphere at 875°C Sintering for 2 hours; the binder uses a polyvinyl alcohol aqueous solution with a mass concentration of 5%, and its dose accounts for 6% of the total mass of the main powder obtained in step (1), so that a low-temperature sintered LTCC microwave dielectric ceramic material can ...

Embodiment 3

[0030] 1) First, more than 99.9% of the analytically pure raw material Li 2 CO 3 、Co 2 o 3 and TiO 2 Moore Billy 2 CO 3 :Co 2 o 3 :TiO 2 = 2:1:6 to prepare the main powder;

[0031] 2) Prepare the obtained powder from step (1) by wet ball milling for 12 hours. The solvent is distilled water. After drying, it is pre-fired in the atmosphere at 900°C for 4 hours, and then the pre-fired powder is crushed, and 4% by weight % low melting point substance H 3 BO 3 .

[0032] 3) Mix the product obtained in step (2) by wet ball milling for 12 hours. The solvent is distilled water. After drying, add a binder and granulate, then press and shape, debinding at 550°C, and finally in an atmosphere at 875°C Sintering for 2 hours; the binder uses a polyvinyl alcohol aqueous solution with a mass concentration of 5%, and its dose accounts for 6% of the total mass of the main powder obtained in step (1), so that a low-temperature sintered LTCC microwave dielectric ceramic material can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Τf | aaaaa | aaaaa |

| Τf | aaaaa | aaaaa |

| Τf | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com