High temperature acidizing corrosion inhibitor and preparation method thereof

An acidifying corrosion inhibitor, high temperature technology, used in chemical instruments and methods, earthwork drilling, wellbore/well components, etc. The effective concentration of propargyl alcohol and other issues can achieve the effects of good acid solubility, significant corrosion inhibition effect and safe use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

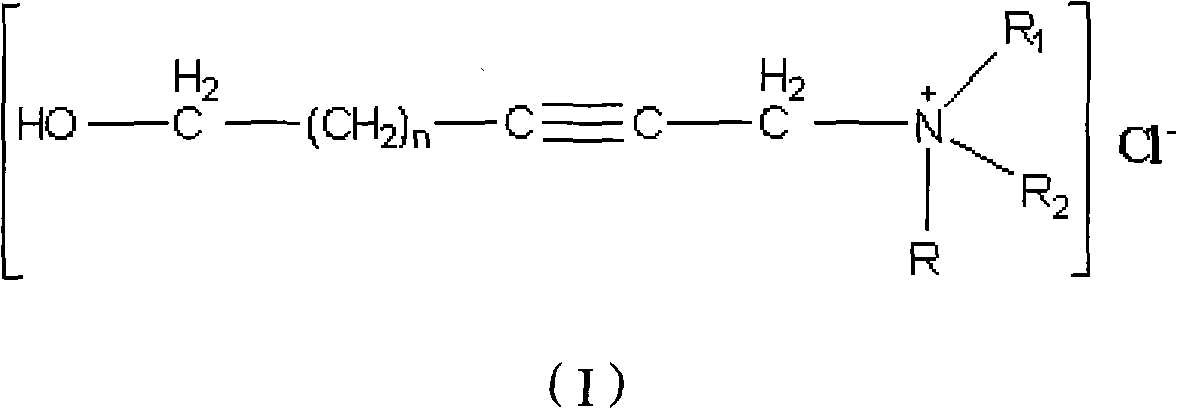

[0033] Put 56 grams of propynyl alcohol, 30 grams of paraformaldehyde, and 107 grams of N-methylaniline into a three-necked flask equipped with a stirring and condensing device, and simultaneously use glacial acetic acid to adjust the pH value to 2-3. Turn on the condensing device and start heating and stirring the reaction. When the reaction temperature reaches 100°C, keep the temperature at reflux for 8 hours to obtain about 190 grams of Mannich base, slowly add 127 grams of benzyl chloride dropwise to the generated Mannich base, keep the temperature at 100°C, and continue the reaction for 5 Hour, obtain the Mannich base quaternary ammonium salt of following formula:

[0034]

[0035] Stir and mix 50 grams of the above-mentioned Mannich base quaternary ammonium salt, 20 grams of dimethylformamide and 30 grams of isopropanol to obtain 100 grams of high-temperature acidification corrosion inhibitor.

[0036] Sustained release performance evaluation:

[0037] The industry ...

Embodiment 2

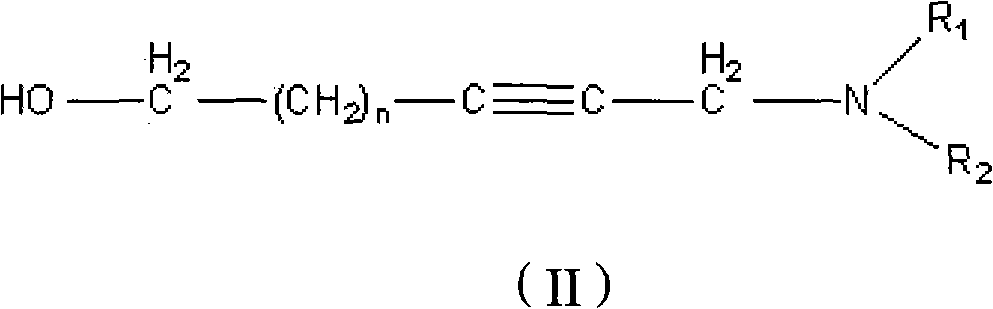

[0043] 84 grams of pentynyl alcohol, 75 grams of formalin aqueous solution (concentration is 40%), and 73 grams of diethylamine were put into a three-necked flask equipped with a stirring and condensing device, while glacial acetic acid was used to adjust the pH value to 2-3. Turn on the condensing device and start heating and stirring the reaction. When the reaction temperature reaches 100°C, keep the temperature at reflux for 8 hours to obtain about 200 grams of Mannich base, slowly add 126 grams of benzyl chloride dropwise to the generated Mannich base, keep the temperature at 100°C, and continue the reaction 5 hours, obtain the Mannich base quaternary ammonium salt of following formula:

[0044]

[0045] Stir and mix 55 grams of the above-mentioned Mannich base quaternary ammonium salt, 15 grams of dimethylformamide and 30 grams of isopropanol to obtain 100 grams of high-temperature acidification corrosion inhibitor.

[0046] Table 2

[0047]

[0048] It can be see...

Embodiment 3

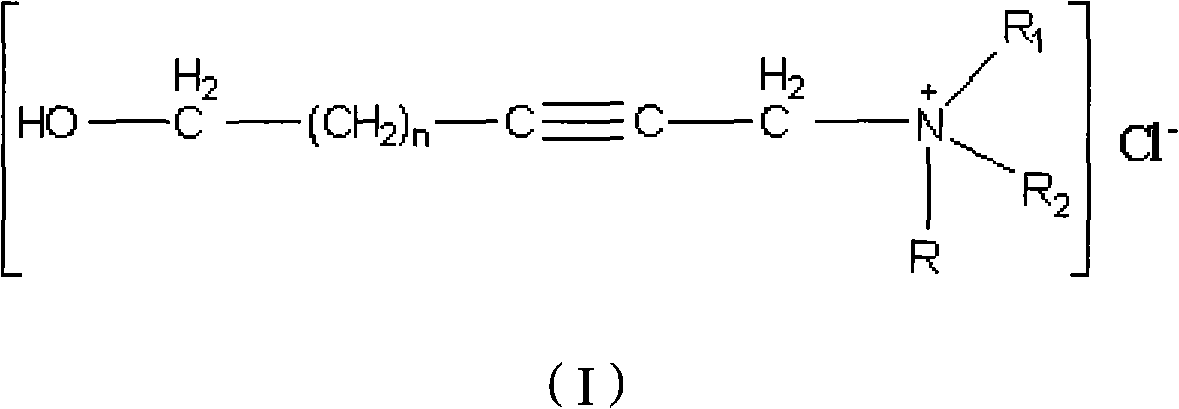

[0050]Put 98 grams of hexynol, 75 grams of formalin aqueous solution (concentration of 40%) and 107 grams of N-methylaniline into a three-necked flask equipped with a stirring and condensing device, while using glacial acetic acid to adjust the pH value to 2-3. Turn on the condensing device and start heating and stirring the reaction. When the reaction temperature reaches 100°C, keep the temperature at reflux for 8 hours to obtain about 250 grams of Mannich base, slowly add 94 grams of chloroacetic acid dropwise to the generated Mannich base, keep the temperature at 100°C, and continue the reaction for 5 hours. A Mannich base quaternary ammonium salt of the formula is obtained:

[0051]

[0052] Stir and mix 60 grams of the above-mentioned Mannich base quaternary ammonium salt, 20 grams of dimethylformamide and 20 grams of isopropanol to obtain 100 grams of high-temperature acidification corrosion inhibitor.

[0053] table 3

[0054]

[0055] It can be seen from the da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com