New multicomponent heterogeneous copper alloy for valve plate casting

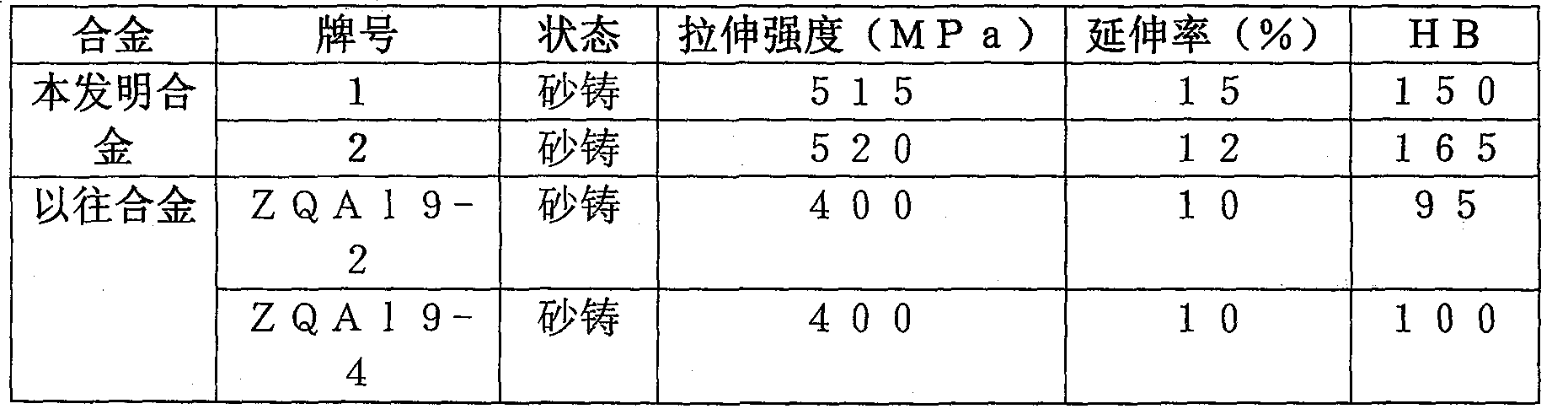

A composite valve plate and copper alloy technology, which is applied in the field of casting copper alloy materials for valve plates, can solve the problems of unsuitable pressure valve parts, poor corrosion resistance, poor compactness, etc., and achieve the improvement of water pressure inspection pass rate and corrosion resistance The effect of improving sexuality and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Take alloy 1 of the present invention as an example.

[0016] 1. Take industrial pure copper (99.5% Cu).

[0017] 2. Ingredients, its chemical composition is 10-12.5% Al, 3.0-5.0% Fe, 0.2-0.5% Mn, ≤1.5% Ni, 0.01-0.02% B, 0.8-1.2% Zn, and the balance is Cu.

[0018] 3. Melt the alloy in an intermediate frequency induction furnace, cover it with dried and dehydrated cryolite, and fill it with N 2 After degassing, pour it into a hollow butterfly valve plate sand mold at 1250-1300°C for 48 hours, and pour tensile and chemical analysis samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com