Method for producing microbial feed additive by utilizing potato vinasse

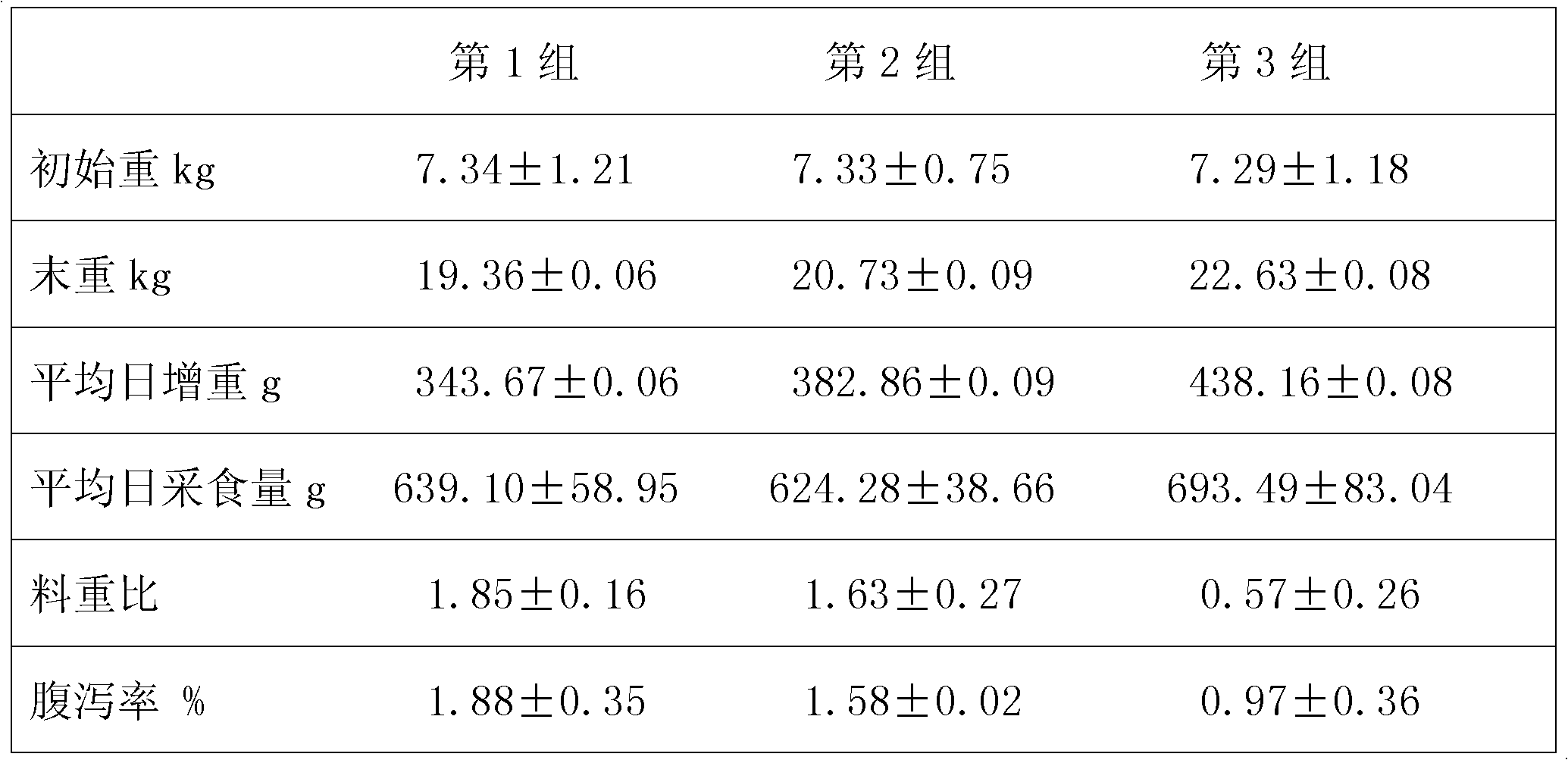

A microbial feed and additive technology, applied in animal feed, animal feed, applications, etc., can solve the problems of high crude fiber content of distiller's grains, limit the use of distiller's grains, and high operating costs, so as to achieve a wide range of applications, improve feed conversion efficiency, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Fresh potato distiller's grains in weight ratio: bran: soybean meal is 5:3:2, fresh potato distiller's grains, bran and soybean meal are mixed, and 1.0% (NH 4 )2 SO 4 , and 0.2% KH 2 PO 4 Make distiller's grains medium, mix the prepared Bacillus subtilis suspension, Trichoderma konningen suspension, and Trichoderma viride in a volume ratio of 1:1:1 and add to the above-mentioned medium, every 100 grams Add 20ml of distiller's grain medium, and after cultivating and fermenting at 28°C for 72h, inoculate 10ml of activated Candida tropicalis per 100g of medium in the fermented medium (the number of bacteria is 1.6×10 6 tropicalis at a ratio of 1 / mL), cultured at 28°C for 120 h, and then dried. After determination, the protein content of the product increased by 42.8%, the cellulose content decreased by 8.3%, and the number of bacillus was 2.1×10 9 cells / mL, the number of yeasts was 1.7×10 7 individual / mL.

Embodiment 2

[0035] Fresh cassava distiller's grains in weight ratio: bran: soybean meal is 5:3:2, fresh cassava distiller's grains, bran and soybean meal are mixed, and 1.5% (NH 4 ) 2 SO 4 , and 0.2% KH 2 PO 4 Make distiller's grains medium, mix the prepared Bacillus subtilis suspension, Trichoderma konningen suspension, and Trichoderma viride in a volume ratio of 1:1:1 and add to the above-mentioned medium, every 100 grams Add 20ml of distiller's grain medium, and after cultivating and fermenting at 29°C for 48h, inoculate 10ml of activated Candida tropicalis per 100g of medium in the fermented medium (the number of bacteria is 3.0×10 6 tropicalis at a ratio of 1 / mL), cultured at 28°C for 120 h, and then dried. It was determined that the protein content of the product increased by 37.8%, the cellulose content decreased by 7.6%, and the number of bacillus was 1.9×10 8 cells / mL, the number of yeasts was 2.7×10 7 individual / mL.

Embodiment 3

[0037] Fresh sweet potato distiller's grains by weight: bran: soybean meal is 5:3:2, fresh sweet potato distiller's grains, bran and soybean meal are mixed, and add 1.2% (NH 4 ) 2 SO 4 , and 0.2% KH 2 PO 4 Make the distiller's grains medium, mix the prepared Bacillus subtilis bran koji, Trichoderma koningensis bran koji, and Trichoderma viride koji in the weight ratio of 1:1:1 and add to the above-mentioned culture medium, every 100 grams of distiller's grains Add 20 grams to the culture medium, cultivate and ferment for 24 hours at 28 ° C, then inoculate 10 ml of activated Candida utilis (the number of bacteria is 1.0 × 10 6 Candida utilis was inoculated at a ratio of 1 / mL), cultured at 28°C for 120 h, and then dried. It was determined that the protein content of the product increased by 38.4%, the cellulose content decreased by 7.9%, and the number of bacillus was 2.0×10 9 cells / mL, the number of yeasts is 1.2×10 7 individual / mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com