Method for producing ethylene glycol-bis (2-aminoethyl ether) tetraacetic acid (EGTA)

A production method, the technology of disodium iminodiacetic acid, which is applied in chemical instruments and methods, the preparation of organic compounds, organic chemistry, etc., can solve the problems that the purity of EGTA cannot meet the requirements of biochemical reagents, etc., so as to improve the yield and equipment Utilization rate, simple reaction principle, and the effect of reducing the concentration of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

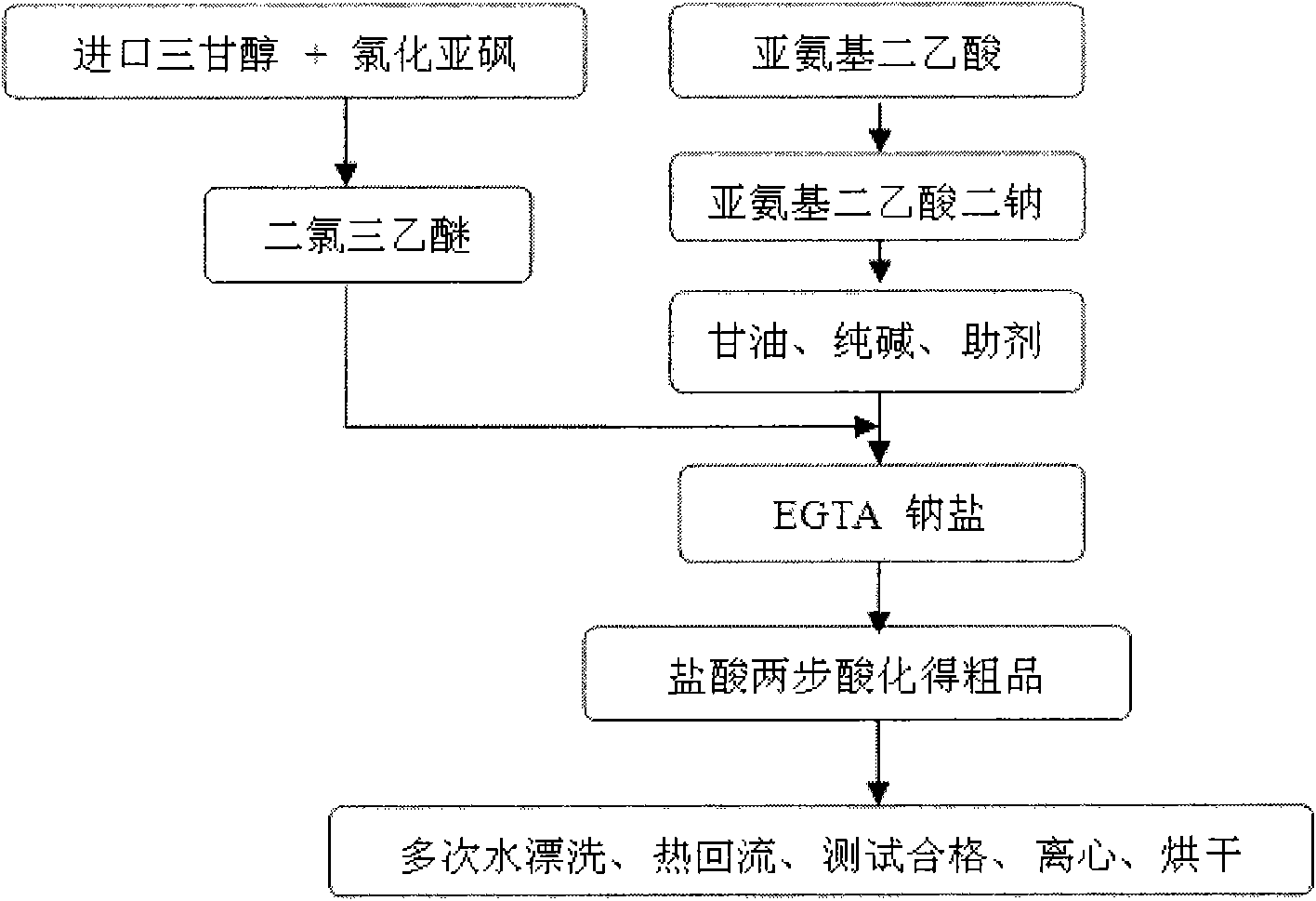

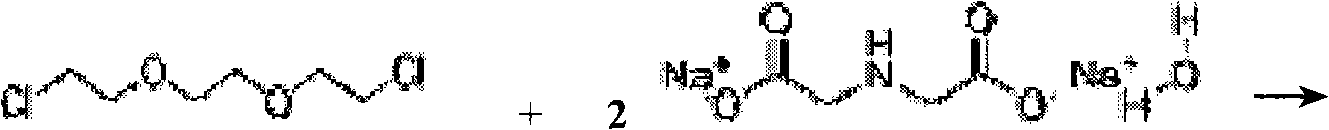

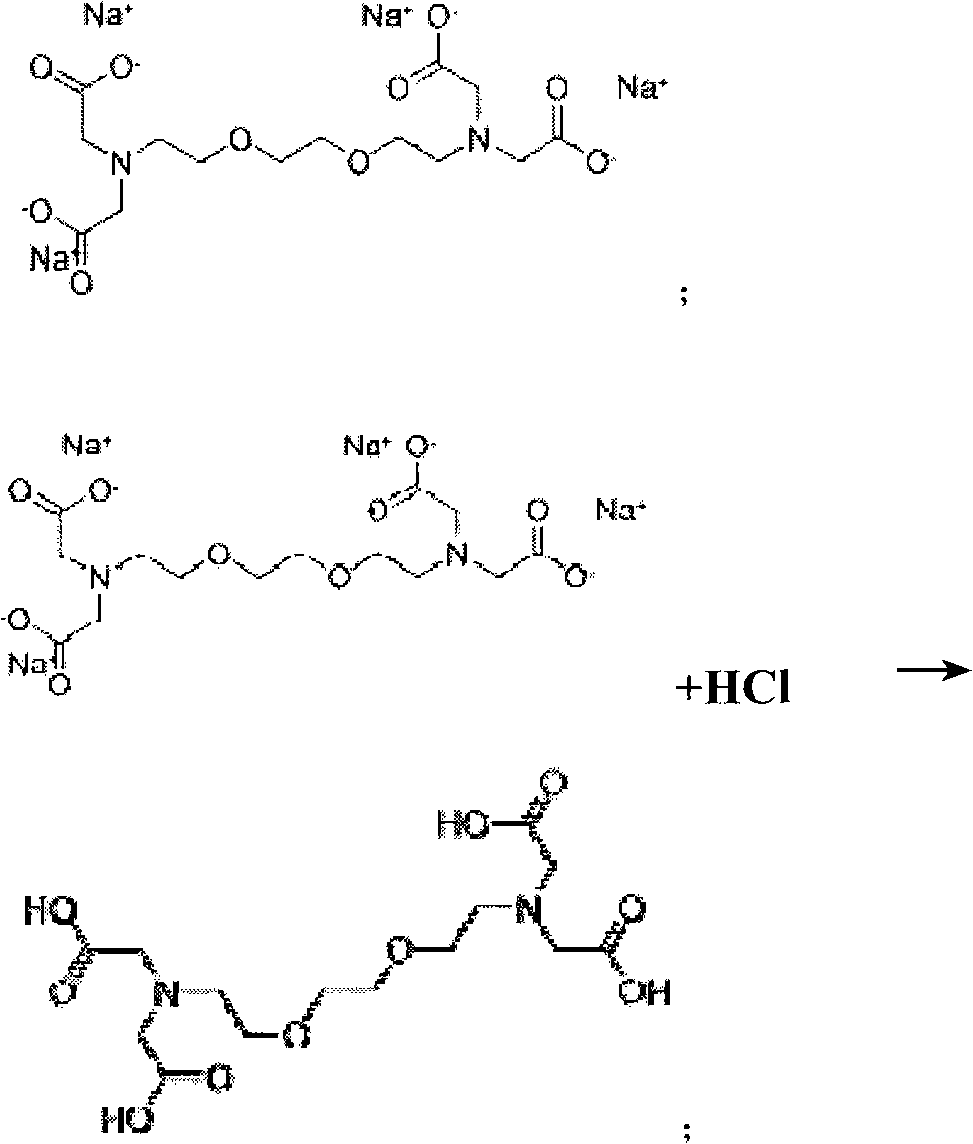

Method used

Image

Examples

Embodiment 1

[0027] Put glycerin into a 500-liter dry reaction pot first, then put in disodium iminodiacetate and sodium carbonate, then slowly raise the temperature to 60°C, then slowly add dichlorotriethyl ether dropwise, and then slowly raise the temperature to 99°C Keep at ℃ for more than 5 hours, then slowly cool naturally to 50℃, slowly add hydrochloric acid dropwise until the pH is 5, slowly raise the temperature to 90℃, filter it into another reaction pot with a filter rod, and then add hydrochloric acid dropwise To pH 1, after standing for 8 hours, add 2 times the amount of water, stir for 20 minutes, dry with a centrifuge, rinse with a large amount of water, rinse with an appropriate amount of methanol, and dry with a centrifuge to obtain a crude product; Dissolve the crude product in boiling water and reflux for about 1 to 1.5 hours; then pour in excess water, stir for 7 hours under boiling, cool to room temperature, then centrifuge, dehydrate and dry to obtain the finished produ...

Embodiment 2

[0029] Put glycerin into a 500-liter dry reaction pot first, then put in disodium iminodiacetate and sodium carbonate, then slowly raise the temperature to 65°C, then slowly add dichlorotriethyl ether dropwise, and slowly raise the temperature to 101 Keep at ℃ for more than 5 hours, then slowly cool naturally to 60℃, slowly add hydrochloric acid dropwise until the pH is 7, slowly raise the temperature to 95℃, filter it into another reaction pot with a filter rod, and then add hydrochloric acid dropwise until the pH is 1.5, after standing for 10 hours, add 4 times the amount of water, stir for 40 minutes, dry with a centrifuge, rinse with a large amount of water, rinse with an appropriate amount of methanol, and dry with a centrifuge to obtain a crude product; Dissolve the crude product in boiling water and reflux for about 2 to 3 hours; then pour in excess water, stir for 9 hours in a boiling state, cool to room temperature, then centrifuge, dehydrate and dry to obtain the fini...

Embodiment 3

[0031] Put glycerin into a 500-liter dry reaction pot first, then put in disodium iminodiacetate and sodium carbonate, then slowly raise the temperature to 60°C, then slowly add dichlorotriethyl ether dropwise, and then slowly raise the temperature to 100°C Keep at ℃ for more than 5 hours, then slowly cool naturally to 55℃, slowly add hydrochloric acid dropwise until there is no solid content in the liquid, then slowly increase the temperature to 90℃, filter it into another reaction pot with a filter stick, and then Then add hydrochloric acid dropwise until the pH is 1, and after standing for 12 hours, add 3 times the amount of water, stir for 30 minutes, dry it with a centrifuge, rinse with a large amount of water, rinse with an appropriate amount of methanol, and shake it with a centrifuge. Dry to obtain the crude product; dissolve the crude product in boiling water and reflux for about 2 to 3 hours; then pour in excess water, stir for 8 hours in a boiling state, cool to room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com