Electroless copper plating method for helical line for travelling wave tube

A technology of electroless copper plating and helical wire, applied in the manufacture of slow wave components, microwave electric vacuum field, can solve the problems of discontinuous conductive surface, uneven coating, poor adhesion of electroplating layer, etc., to achieve good inner and outer surface consistency, The effect of good coating uniformity and good coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Preparation of electroless copper plating solution: Prepare copper plating electrolyte according to the following ingredients: copper sulfate 250g / L, sulfuric acid 60g / L, absolute ethanol 50g / L; take copper sulfate according to the calculated quantity, and dissolve copper sulfate in Filter hot water at 60°C into the tank, cool to room temperature, add a certain amount of sulfuric acid while stirring, then add absolute ethanol, pour the required amount of tap water into the tank, and stir the electrolyte with a stirring fixture.

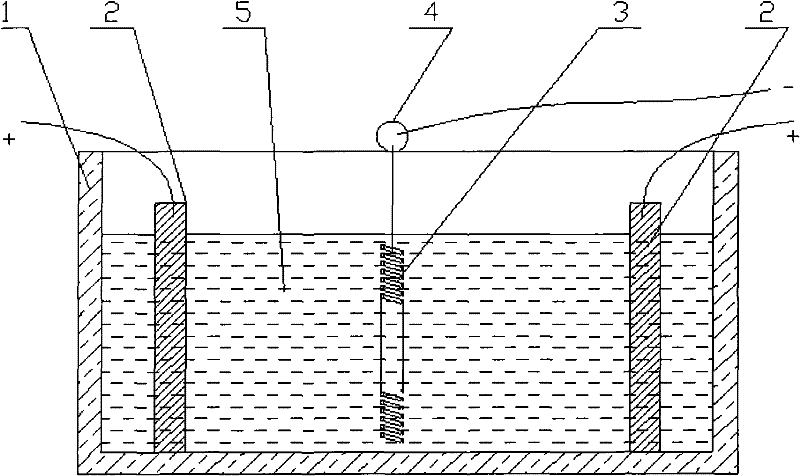

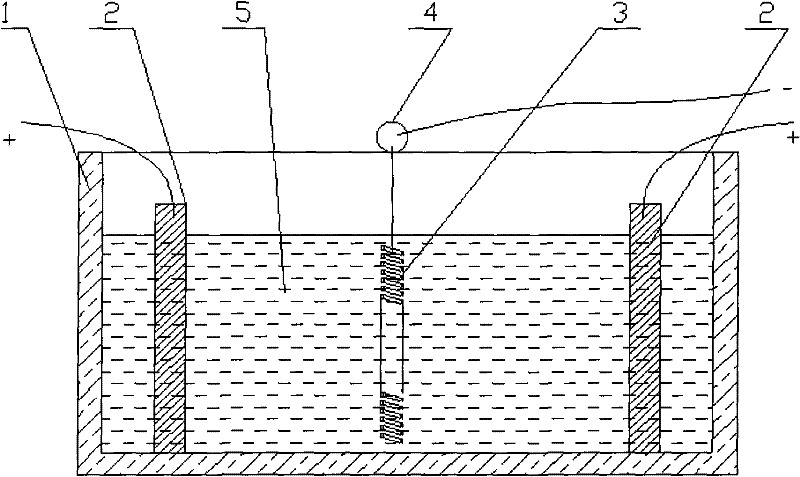

[0014] 2. Put the two copper anode plates 2 required for electroplating into the electroplating solution 5 of the electroplating tank 1, place them on both sides of the electroplating position respectively, and connect the anode of the electroplating power supply; connect a cleaned copper rod 4 to the electroplating The cathode of the power supply is placed above the electroplating solution; the spiral wire 3 that has been chemically cleaned ...

Embodiment 2

[0020] 1. Preparation of electroless copper plating solution: Prepare copper plating electrolyte according to the following ingredients: copper sulfate 250g / L, sulfuric acid 60g / L, absolute ethanol 50g / L; take copper sulfate according to the calculated quantity, and dissolve copper sulfate in Filter hot water at 70°C into the tank, cool to room temperature, add a certain amount of sulfuric acid while stirring, then add absolute ethanol, pour the required amount of tap water into the tank, and stir the electrolyte with a stirring fixture.

[0021] 2. Put the two copper anode plates 2 required for electroplating into the electroplating solution 5 of the electroplating tank 1, respectively place them on both sides of the electroplating position, and connect the anode of the electroplating power supply; connect a cleaned copper rod 4 to the electroplating The cathode of the power supply is placed above the electroplating solution; the spiral wire 3 that has been chemically cleaned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com