Method for separating collophanite

A beneficiation method and a technology for collophosphate rock, which are applied in flotation, solid separation and other directions to achieve the effects of reducing energy consumption and dosage of chemicals, high selectivity, and simplifying the system of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

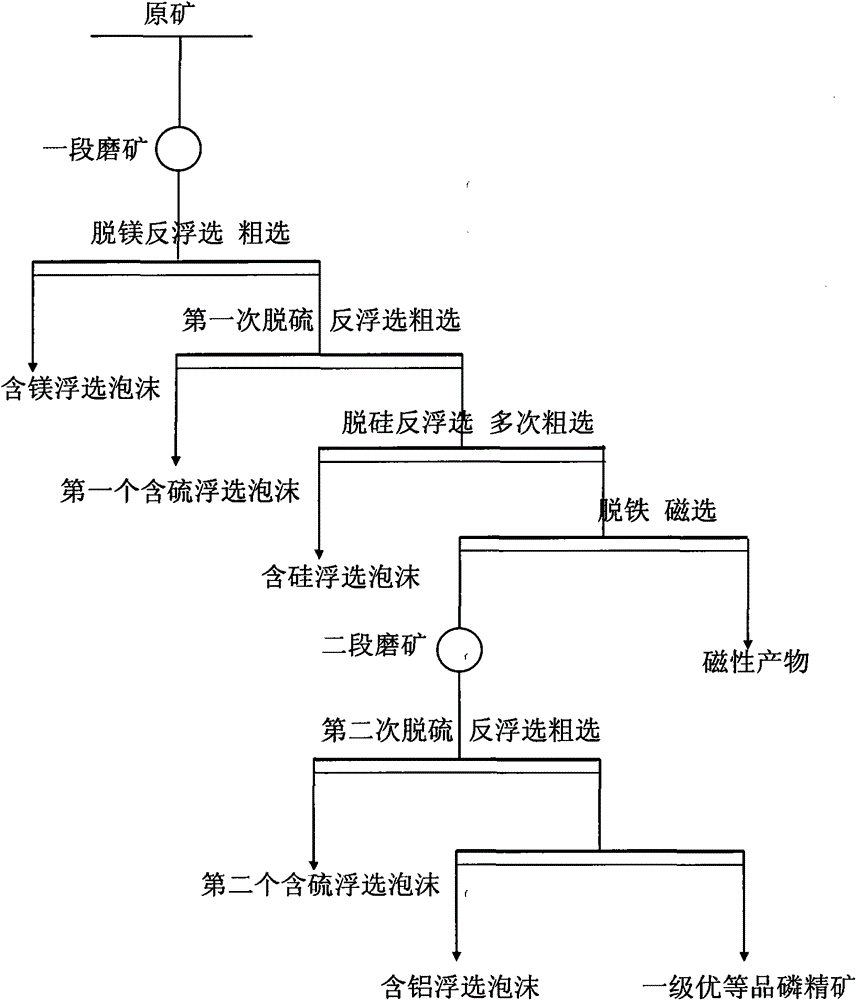

Image

Examples

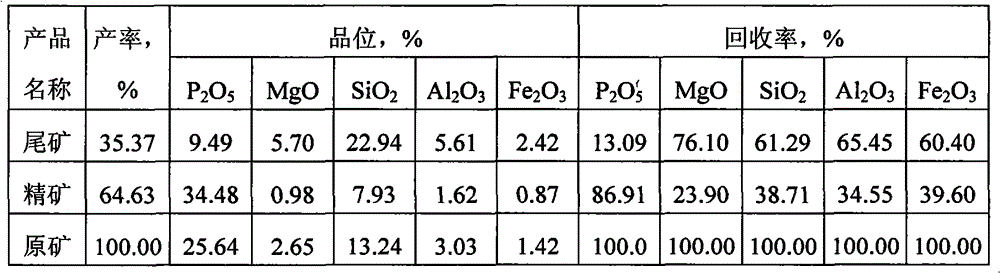

Embodiment 1

[0043] Silica-calcium collophane ore P 2 O 5 25.64%, MgO 2.65%, SiO 2 13.24%, Al 2 O 3 3.03%, Fe 2 O 3 1.42%. The process of beneficiation and impurity removal includes: rough grinding of the original ore (grinding fineness -0.074mm grain size accounts for 45%), adding water to control the slurry concentration to 35%; the reagent system used in the reverse flotation of coarse grinding products for demagnesization is: adjustment Sulfuric acid 10kg / t, stearic acid 350g / t, a rough separation of 6 minutes, the flotation foam is magnesium-containing tailings, the slurry in the tank is further desulfurized (pyrite); the slurry in the tank is the first reverse flotation The reagent system used for desulfurization is: xanthate 50g / t, a rough separation of 6 minutes, the flotation foam is the first sulfur-containing tailings, and the slurry in the tank is further desiliconized; the slurry in the tank is desiliconized by reverse flotation for 4 times , Each 4 minutes, the reagent syst...

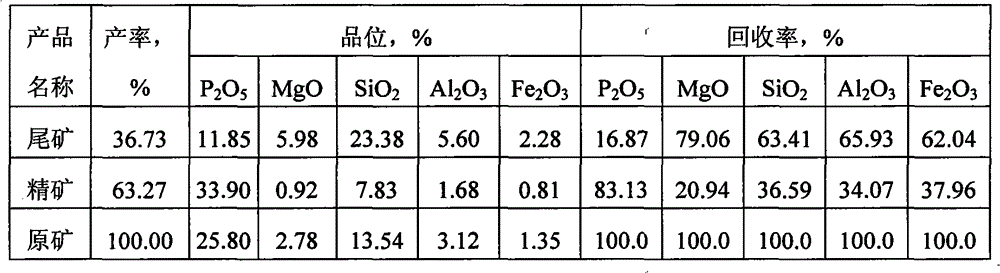

Embodiment 2

[0047] Silica-calcium collophane ore P 2 O 5 25.80%, MgO 2.78%, SiO 2 13.54%, Al 2 O 3 3.12%, Fe 2 O 3 1.35%. The process of beneficiation and impurity removal includes: rough grinding of the original ore (grinding fineness -0.074mm grain size accounted for 55%), adding water to control the slurry concentration to 35%; the reagent system used in the reverse flotation of coarse grinding products for demagnesization is: adjustment Sulfuric acid 10kg / t, oleic acid 350g / t, a rough separation of 6 minutes, the flotation foam is magnesium-containing tailings, the slurry in the tank is further desulfurized (pyrite); the slurry in the tank is desulfurized by reverse flotation for the first time The reagent system adopted is: Xanthate 50g / t, a rough separation of 6 minutes, the flotation foam is the first sulfur-containing tailings, and the slurry in the tank is further desiliconized; the slurry in the tank is desiliconized by reverse flotation for 4 times. Each 4 minutes, the reagen...

Embodiment 3

[0051] Silica-calcium collophane ore P 2 O 5 24.84%, MgO 2.87%, SiO 2 14.32%, Al 2 O 3 3.23%, Fe 2 O 3 1.26%. The process of beneficiation and impurity removal includes: rough grinding of the original ore (grinding fineness -0.074mm grain size accounts for 65%), adding water to control the slurry concentration to 35%; the reagent system used in the reverse flotation demagnesization of the rough grinding product is: adjustment Sulfuric acid 10kg / t, oleic acid 350g / t, a rough separation of 6 minutes, the flotation foam is magnesium-containing tailings, the slurry in the tank is further desulfurized (pyrite); the slurry in the tank is desulfurized by reverse flotation for the first time The reagent system adopted is: Xanthate 50g / t, a rough separation of 6 minutes, the flotation foam is the first sulfur-containing tailings, and the slurry in the tank is further desiliconized; the slurry in the tank is desiliconized by reverse flotation for 4 times. Each 4 minutes, the reagent s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com