Method for extracting humic acid liquid fertilizer with rich trace elements from sludge

A technology of trace elements and humic acid, which is applied in oxidation treatment of sludge, dehydration/drying/concentrated sludge treatment, organic fertilizer, etc., can solve the problems of soil heavy metal pollution, low fertilizer efficiency of products, and long secondary fermentation time, etc. Achieve significant reduction effect, improve soil physical properties, and promote the accumulation of sugar and dry matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

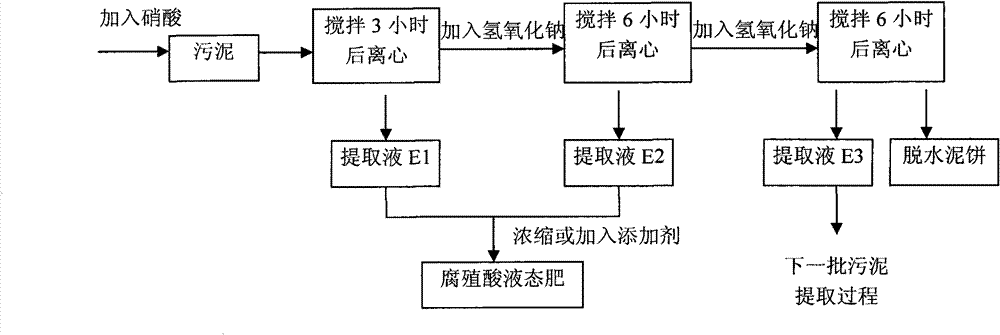

Image

Examples

Embodiment 1

[0018] The main indicators of sludge in a sewage treatment plant are shown in Table 1.

[0019] Table 1 Main indicators of sludge in a sewage treatment plant

[0020] indicators

[0021] Place the sludge in a mixing tank, add 0.5mol / L nitric acid (0.2L / kg sludge) to it, stir at a speed of 5 rpm for 3 hours and then stir at a speed of 4000 rpm Centrifuge to collect the extract E1. Add 0.1 mol / L sodium hydroxide (addition amount is 1L / kg sludge) to the precipitation, stir and extract at a speed of 5 rpm for 6 hours, then centrifuge at a speed of 4000 rpm, collect the extract and record it as E2, Then add 0.1mol / L sodium hydroxide (addition amount is 1L / kg sludge) to adjust the precipitation, stir and extract at a speed of 5 rpm for 6 hours, then carry out high-pressure mechanical dehydration, collect the extract and record it as E3, dehydrated cake The moisture content is 38%. Mix E1 and E2, the measured content of humic acid in the mixed solution is 2.1%, and the c...

Embodiment 2

[0023] The main indicators of a paper mill sludge are shown in Table 2.

[0024] Table 2 The main indicators of a paper mill sludge

[0025] indicators

[0026] Place the sludge in a stirring tank, add 0.55mol / L nitric acid (0.3L / kg sludge) to it, stir at a speed of 5 rpm for 3 hours and then stir at a speed of 4000 rpm Centrifuge to collect the extract E1. Add 0.1mol / L sodium hydroxide (1.1L / kg sludge) to the precipitate, stir and extract at 5 rpm for 6 hours, then centrifuge at 4000 rpm, collect the extract and record it as E2 , and then add 0.1mol / L sodium hydroxide (addition amount is 1L / kg sludge) to adjust, and then carry out high-pressure mechanical dehydration after stirring and extracting at a speed of 5 rpm / min for 6 hours, collect the extract and record it as E3, and dehydrate The moisture content of the cake was 35%. Mix E1 and E2, the measured content of humic acid in the mixed solution is 2.9%, and the content of trace elements (Fe, Mn, Cu, Zn, Mo, B...

Embodiment 3

[0028] The main indicators of sludge in a sewage treatment plant are shown in Table 3.

[0029] Table 3 Main indicators of sludge in a sewage treatment plant

[0030] indicators

[0031] Place the sludge in a stirring tank, add 0.6mol / L nitric acid (0.15L / kg sludge) to it, stir at a speed of 5 rpm for 3 hours and then stir at a speed of 4000 rpm Centrifuge to collect the extract E1. Add 0.15mol / L sodium hydroxide (addition amount is 0.8L / kg sludge) to the sedimentation, stir and extract at 5 rpm for 6 hours, then centrifuge at 4000 rpm, collect the extract and record it as E2 , and then add 0.15mol / L sodium hydroxide (addition amount is 0.8L / kg sludge) to adjust, and then carry out high-pressure mechanical dehydration after stirring and extracting at a speed of 5 rpm / min for 6 hours. Collect the extract and record it as E3. The moisture content of the cement cake is 37%. Mix E1 and E2, the measured content of humic acid in the mixed solution is 2.0%, and the conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com