High-density lithium manganate anode material and preparation method thereof

A high-density lithium manganate, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of seldom use, high cost, complex process, etc., and achieve volume specific capacity improvement, small investment, and safety. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Adopt the following steps to prepare lithium manganate cathode material:

[0039] (1) select the lithium carbonate that selects purity as 99.5%, the electrolytic manganese dioxide that purity is 92% as raw material, analyze pure Sb 2 o 5 and nano Al 2 o 3 As the dopant M1, according to the molar ratio of Li: Mn: Sb: Al = 1.12: 1.9: 0.05: 0.05, mix evenly by dry ball milling;

[0040] (2) Put the mixed raw material into a high-temperature furnace to heat up, keep it warm at 920°C for 4 hours, and cool down with the furnace;

[0041] (3) Take out the above-mentioned once-synthesized material, add 0.5wt% Nb 2 o 5 and 0.3wt% CuO as the dopant M2, the materials are mixed uniformly by dry ball milling;

[0042] (4) Place the uniformly mixed material in a high-temperature furnace, heat up to 800°C, keep it warm for 8 hours, and then cool with the furnace;

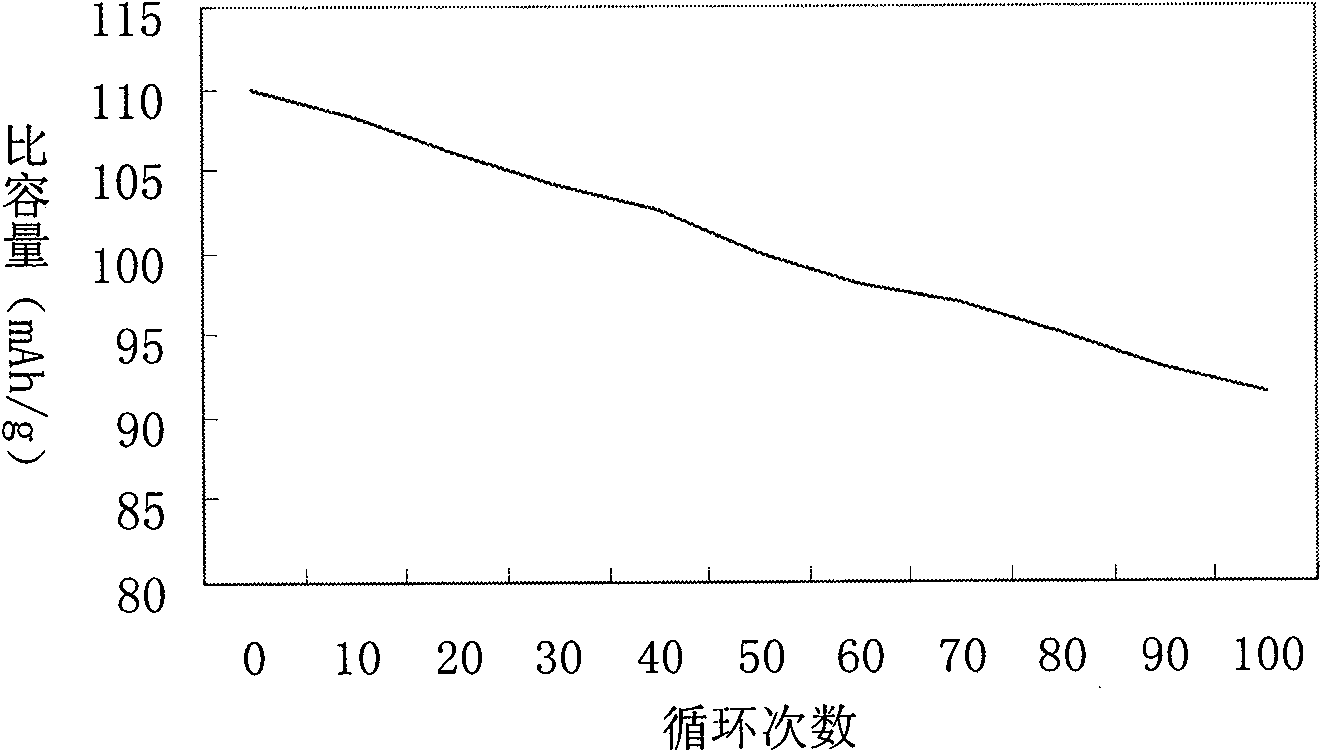

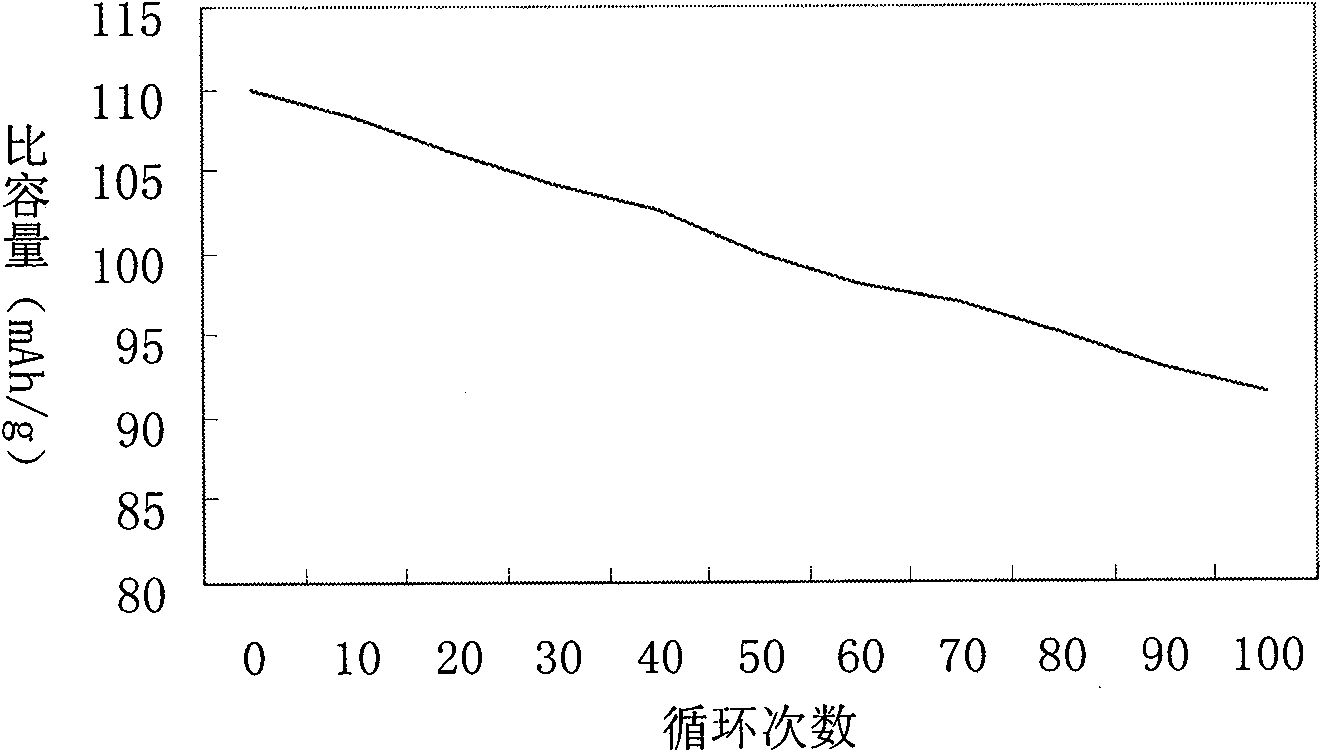

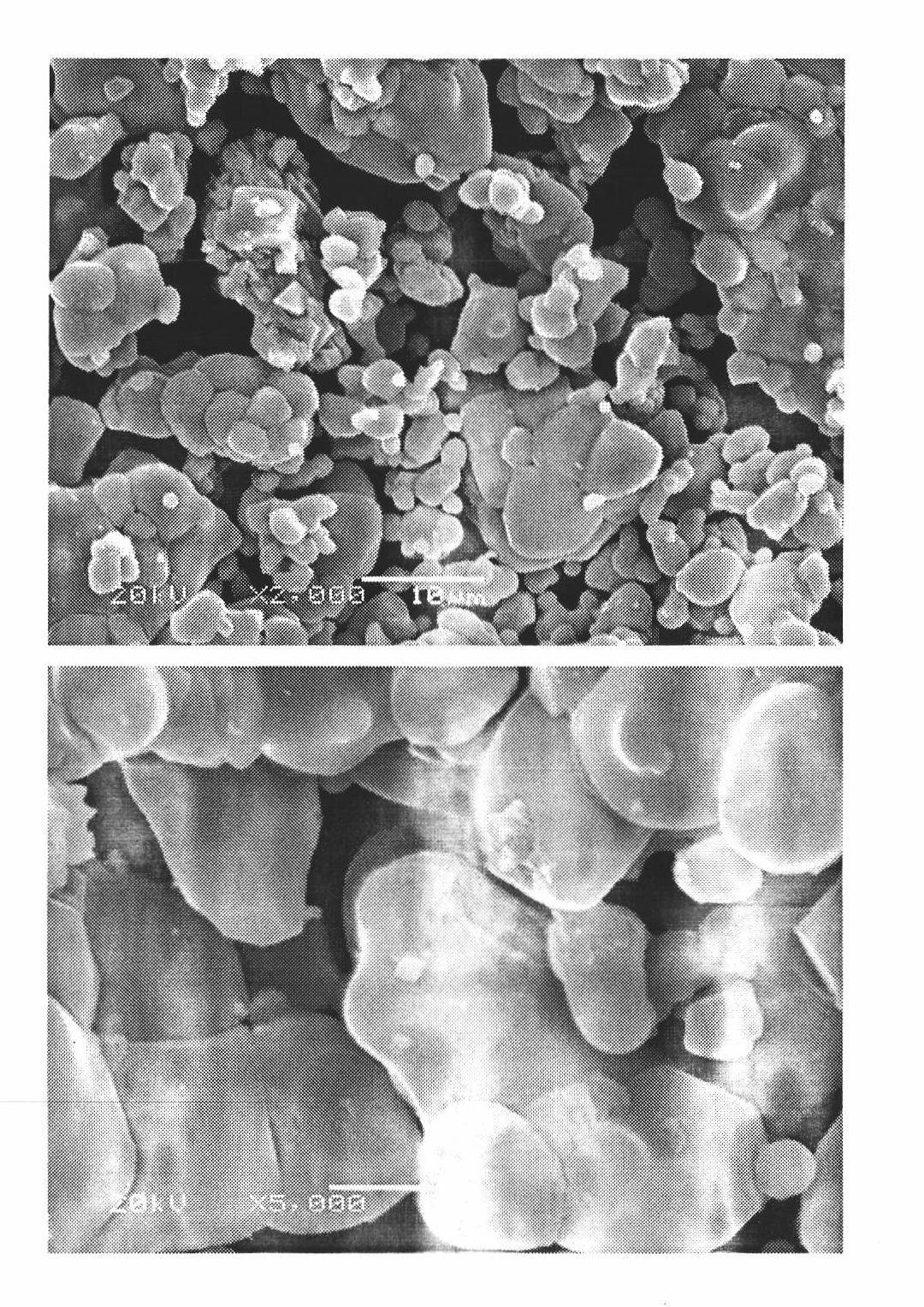

[0043] (5) The secondary synthesis material is crushed and sieved to obtain the lithium manganate positive electro...

Embodiment 2

[0048] Adopt the following steps to prepare lithium manganate cathode material:

[0049] (1) select the lithium carbonate that selects purity as 99.5%, the electrolytic manganese dioxide that purity is 92% as raw material, analyze pure Sb 2 o 5 , Nano Al 2 o 3 and analytically pure Co 3 o 4 As the dopant M1, according to the molar ratio of Li: Mn: Sb: Al: Co = 1.12: 1.87: 0.05: 0.04: 0.04, mix evenly by dry ball milling;

[0050] (2) Put the mixed raw material into a high-temperature furnace to heat up, keep it warm at 940°C for 3 hours, and cool down with the furnace;

[0051] (3) Take out the above-mentioned once-synthesized material, add 0.6wt% Nb 2 o 5 and 0.3wt% CuO as the dopant M2, the materials are mixed uniformly by dry ball milling;

[0052] (4) Place the uniformly mixed material in a high-temperature furnace, heat up to 850°C, keep it warm for 8 hours, and then cool with the furnace;

[0053] (5) The secondary synthesis material is crushed and sieved to obt...

Embodiment 3

[0056] Lithium manganate cathode material is prepared according to the method and steps of Example 1, but there are following differences:

[0057] The dopant M1 in step (1) is TiO 2 、Cr 2 o 3 And cerium oxide, its molar ratio is Li: Mn: M1=0.96: 1.99: 0.012;

[0058] In step (2), put it into a high-temperature furnace to heat up, keep the temperature at 900° C. for 6 hours, and cool down with the furnace;

[0059] Add V in step (3) 2 o 5 , CuO, and ZnO are used as the dopant M2, and the dopant M2 added accounts for 2.0wt% of the lithium manganese oxide powder;

[0060] In step (4), the uniformly mixed material is placed in a high-temperature furnace, heated to 750° C., kept for 8 hours, and then cooled with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com