Heat-preserving decorative mortar and preparation method thereof

A technology of decorative mortar and thermal insulation aggregate, which is applied in the field of building materials, can solve the problems of mortar efflorescence, lack of thermal insulation effect, etc., and achieve the effects of low bulk density, enhanced hydrophobic function, and reduced self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

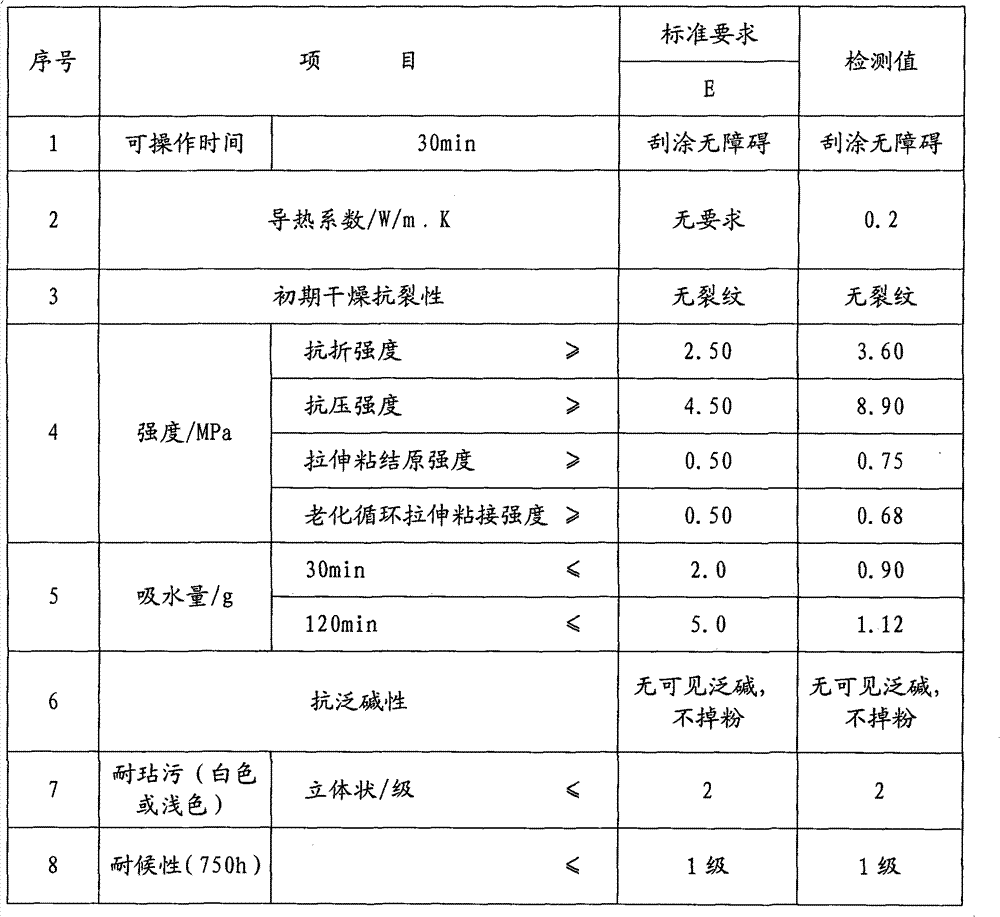

Examples

Embodiment 1

[0014] Embodiment 1: A kind of thermal insulation decorative mortar, its component and weight content are as follows: 180 parts of Lingyun brand ordinary Portland cement 42.5, 70 parts of fly ash, 560 parts of sand, 70 parts of Shuangfei powder, broken foaming 60 parts of polyurethane foam particles, 9 parts of bentonite, 4 parts of TECHNOCEL 1004-7N wood fiber, 2 parts of Elotex SEAL80 water repellent, 5 parts of Elotex ERA100 pan-alkali inhibitor, 4 parts of Bermocoll M30 cellulose ether, Wacker VINNAPAS 5044N rubber powder 15 parts, Shanghai Yipin S110 iron oxide red pigment 1 part.

Embodiment 2

[0015] Embodiment 2: A kind of thermal insulation decorative mortar, its component and weight content are as follows: white silicate 42.5 cement 200 parts, fly ash 50 parts, sand 580 parts, Shuangfei powder 80 parts, the foamed polyurethane foam through breaking 30 parts of particles, 40 parts of expanded vitrified microbeads, 5 parts of bentonite, 5 parts of TECHNOCEL 1004-7N wood fiber, 4 parts of Wacker SILRES Powder D (69051VP) water repellent, 3 parts of Elotex ERA100 pan-alkaline inhibitor, Bermocoll M30 2 parts of cellulose ether, 10 parts of Elotex FX7000 rubber powder, 15 parts of Shanghai Yipin S930 iron oxide yellow pigment.

Embodiment 3

[0016] Embodiment 3: A kind of thermal insulation decorative mortar, its component and weight content are as follows: 220 parts of Lingyun brand ordinary Portland cement 42.5, 40 parts of fly ash, 600 parts of sand, 100 parts of Shuangfei powder, broken foam 20 parts of polyurethane foam particles, 40 parts of expanded vitrified microbeads, 3 parts of bentonite, 8 parts of TECHNOCEL 1004-7N wood fiber, 7 parts of Elotex SEAL80 water repellent, 2 parts of Elotex ERA100 pan-alkali inhibitor, 0.5 parts of Bermocoll M30 cellulose ether 6 parts of Wacker VINNAPAS 5044N rubber powder, 30 parts of Shanghai Yipin S340 iron oxide black pigment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com