Biological starch-based (sheet) degradation master batch

A bio-starch and masterbatch technology, applied in the field of plastic masterbatch, can solve the problems of lack of high-tech transformation value-added, low profit and low profit in starch processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

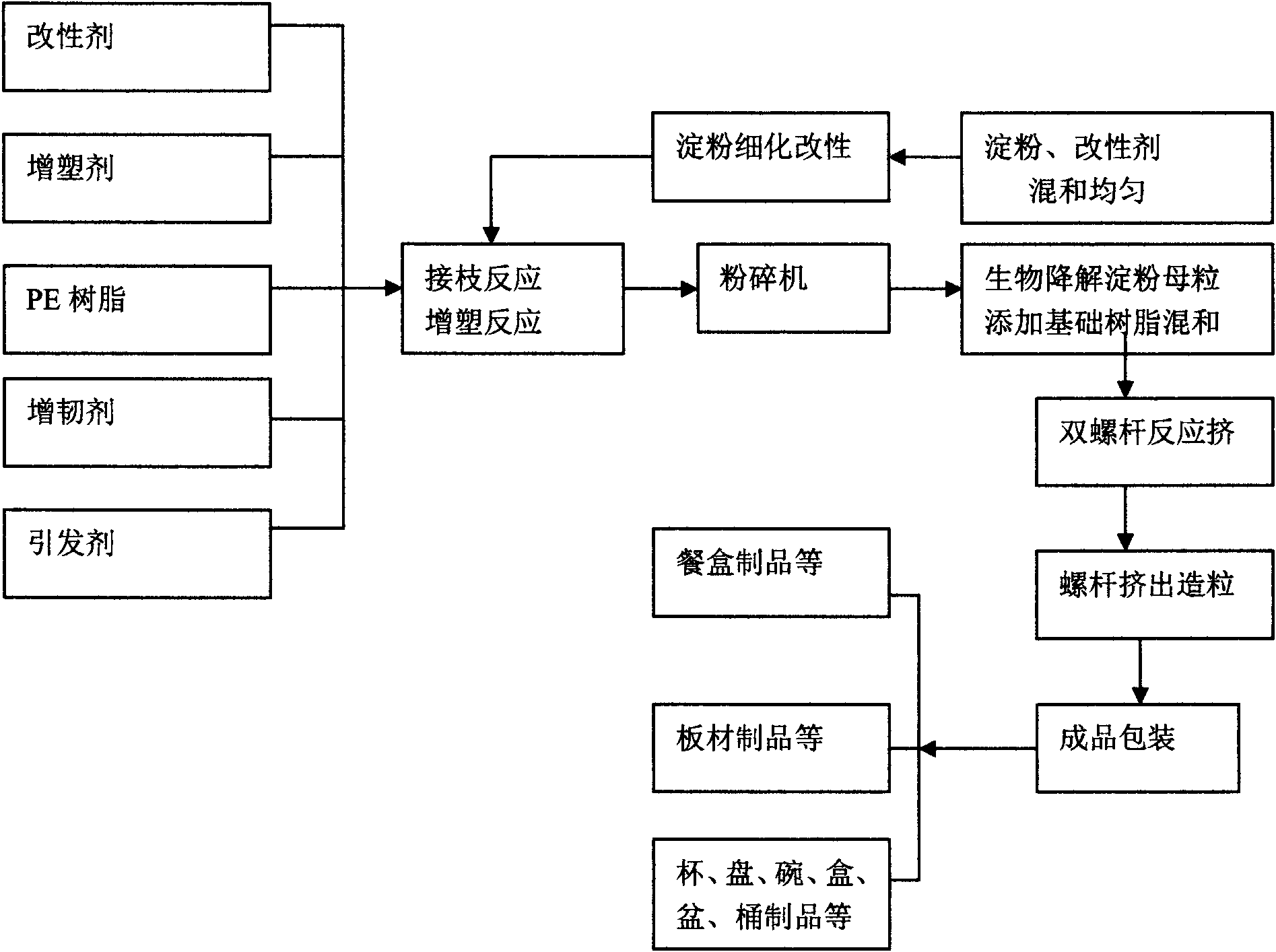

Method used

Image

Examples

Embodiment 1

[0025] Starch refining process, wherein, in the starch refining process, starch and stearic acid are stirred at a low speed for 2 minutes (minutes) in a high-mixing pot at normal temperature, and the rotating speed is adjusted to a high speed stirring for 3 minutes (minutes), and the rotating speed is adjusted to a low speed and then discharged. Transfer the mixed material into the refiner, classification speed: 1000r / min (rotation per minute), refine to 1500 mesh;

[0026] Starch high-speed mixing process; in which, firstly, the materials are accurately weighed, glycerin and ethylene glycol are weighed and mixed evenly, and the starch is added to the high-mixer, and then plasticizer is added to the high-mixer, and the high-mixer is started. Run at high speed for 5 minutes (minutes), switch to high speed operation for 5 minutes (minutes), and then switch to medium speed operation; slowly add maleic anhydride into the high-mixing pot, stir at medium speed for 2 to 3 minutes (min...

Embodiment 2

[0032] Basic plastic resins include: high-density polyethylene (HDPE), polypropylene (PP), polystyrene (PS); among them, by weight, 30% of biological starch degradation masterbatch, 68% of basic plastic resin, and 2% of self-oxidizing agent.

Embodiment 3

[0034] The basic plastic resins are: high-density polyethylene (HDPE), polypropylene (PP), polystyrene (PS); among them, by weight, the biological starch degradation masterbatch is 80%, the basic plastic resin is 18%, and the self-oxidizing agent is 2%.

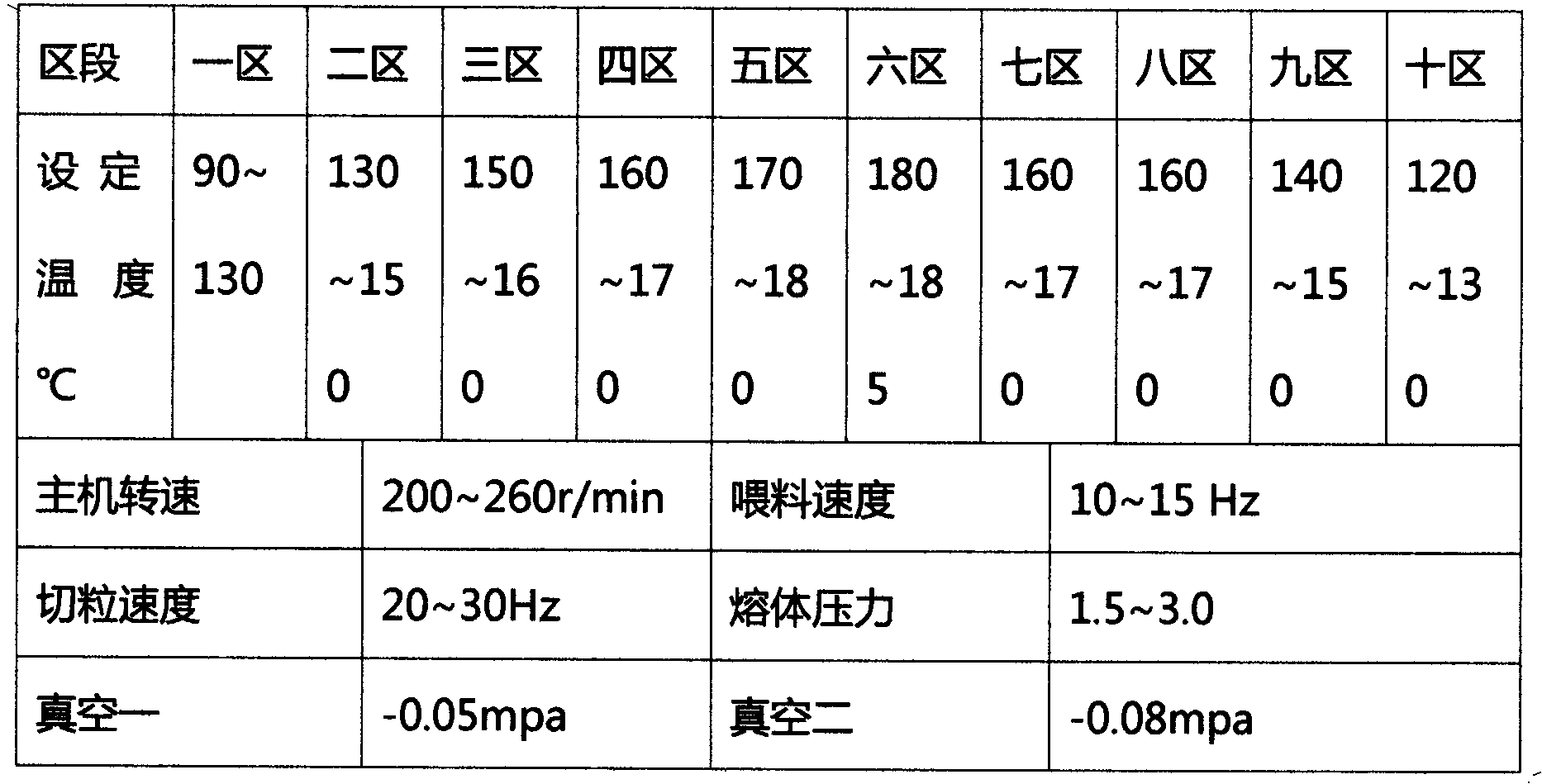

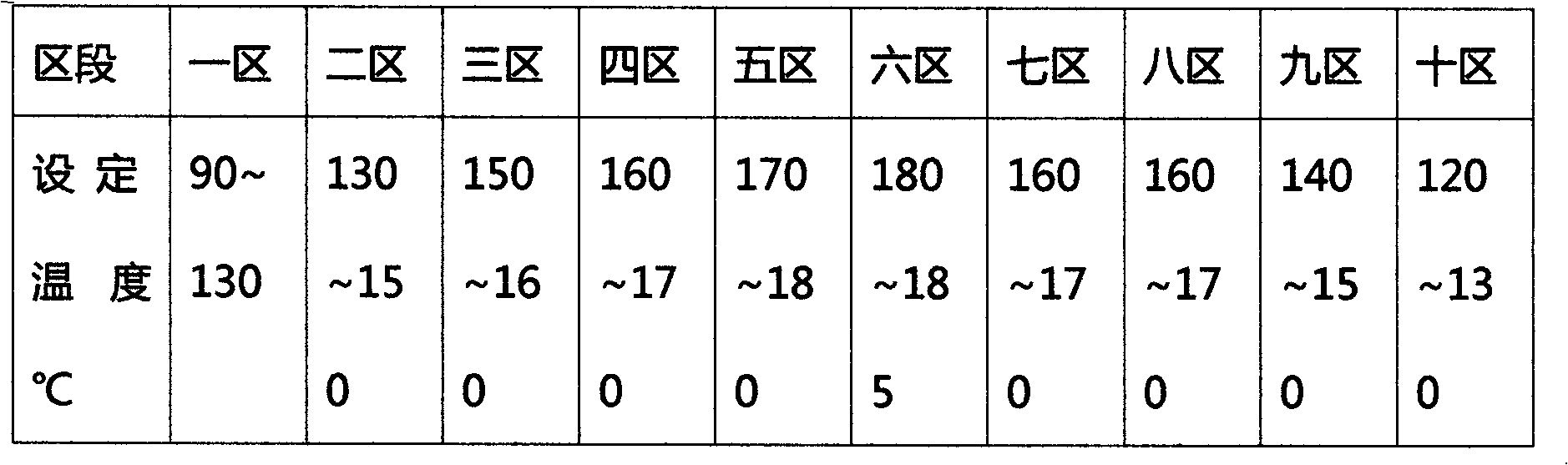

[0035] In the foregoing embodiments, the set temperature of the extruder is divided into sections, which are respectively:

[0036]

[0037]

[0038] Among them, the main engine speed of the extruder is 200-260r / min, the feeding speed is 10-15Hz, the cutting speed is 20-30Hz, the melt pressure is 1.5-3.0; vacuum one: -0.05mpa; vacuum two: -0.08mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com