Methanol diesel fuel and preparation method thereof

A diesel and methanol technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of methanol diesel with short shelf life, inability to store for a long time, and low dispersion, and achieve industrial production, good stability, and preparation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

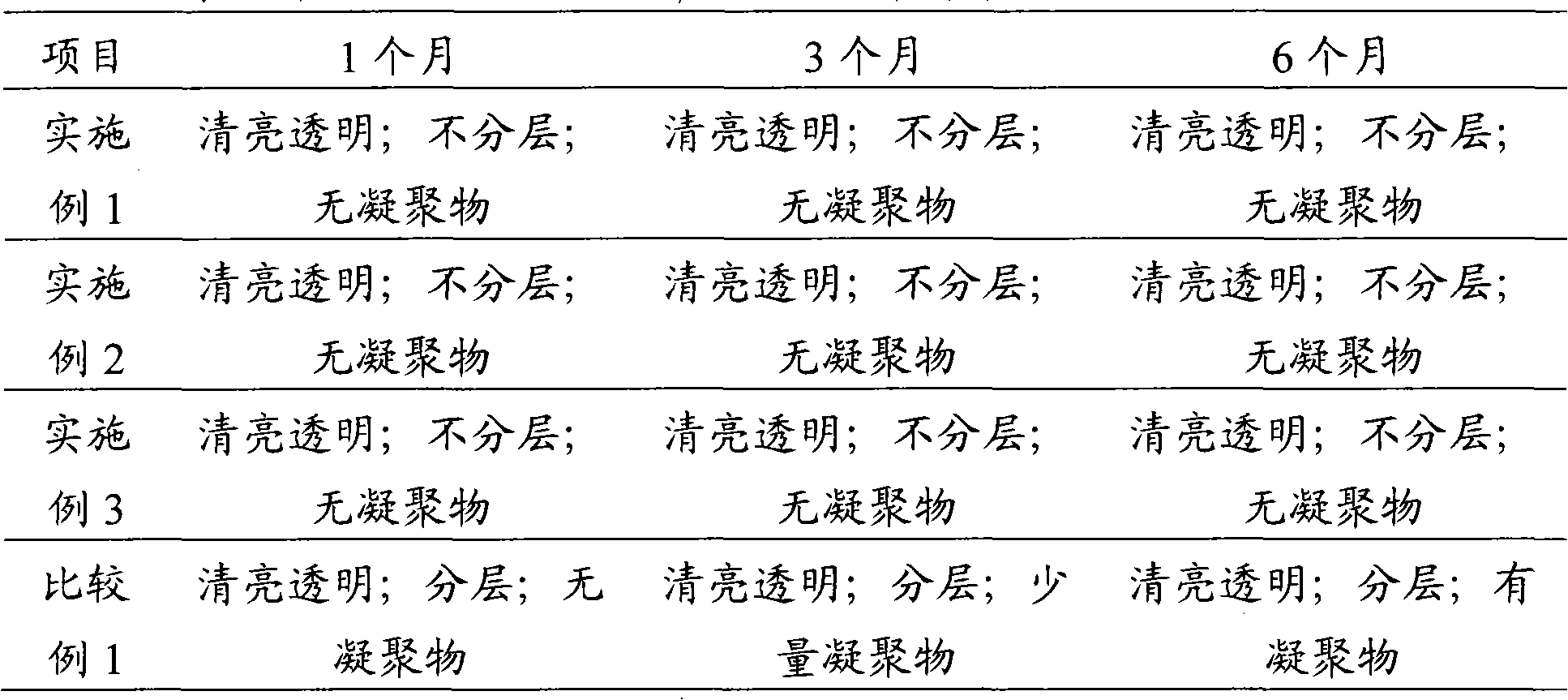

Examples

preparation example Construction

[0053] The present invention also provides the preparation method of the methanol diesel described in the above technical scheme, comprising:

[0054] Mix the diesel oil and the surfactant uniformly, add methanol, and mix uniformly to obtain a microemulsion, and the hydrophilic-lipophilic balance value of the surfactant is 3-6;

[0055] Add co-surfactant and auxiliary agent into the microemulsion, and mix uniformly to obtain methanol diesel.

[0056] In the present invention, firstly, the diesel oil and the surfactant are mixed evenly, the mixing method is preferably stirring, and the stirring time is preferably 3min to 5min; then methanol is added to continue mixing uniformly to obtain a microemulsion, and the mixing method is preferably stirring , the stirring time is preferably 3 min to 5 min. Under the action of surfactant, methanol and diesel form a water-in-oil microemulsion.

[0057] Add co-surfactant and auxiliary agent into the microemulsion, and continue to mix eve...

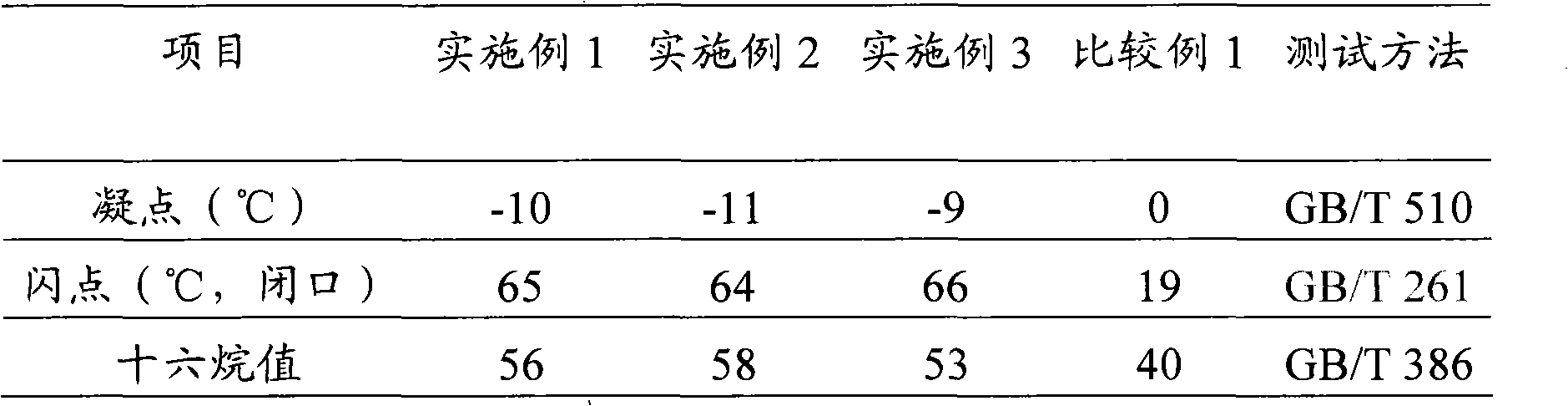

Embodiment 1

[0061] Mix 8L0 diesel oil with 0.05L surfactant at room temperature. The surfactant is obtained by compounding Span-80 and Tween-20 at a mass ratio of 9:1. The HLB value is 4.5. After stirring for 3 minutes, add 1L methanol , continue to stir 3min, obtain microemulsion; Add 0.9L n-dodecyl alcohol and 0.05L auxiliary agent in the obtained microemulsion, obtain methanol diesel oil after stirring 3min, comprise in the described auxiliary agent: the oleic acid of 4 weight parts; 2 weight parts The alkylphenol sulfonate of part; The zinc dialkoxy dithiocarbamate of 0.5 part by weight; The dioxysilane oil of 0.5 part by weight; The isooctyl nitrate of 1 part by weight; The cyclopentadicene of 0.5 part by weight Iron; 1.5 parts by weight of triethanolamine.

[0062] The methanol diesel is observed, and its appearance is clear and transparent.

[0063] The methanol diesel is scanned by an electron microscope, and its particle size is 40nm-150nm, which shows that the methanol diesel i...

Embodiment 2

[0069] Mix 6.3L0 diesel oil with 0.06L OP emulsifier with an HLB value of 3.8 at room temperature, add 2L methanol after stirring for 5 minutes, and continue stirring for 5 minutes to obtain a microemulsion; add 1.6L n-octanol and 0.05L Auxiliary agent, after stirring for 5min, methanol diesel oil is obtained, and the auxiliary agent includes: 6 parts by weight of oleic acid; 4 parts by weight of alkylphenol sulfonate; 1 part by weight of zinc dialkoxy dithiocarbamate; 1 part by weight of dioxysilicone oil; 3 parts by weight of isooctyl nitrate; 1 part by weight of cyclopentaferrocene; 3 parts by weight of triethanolamine.

[0070] The methanol diesel is observed, and its appearance is clear and transparent.

[0071] The methanol diesel is scanned by an electron microscope, and its particle size is 40nm-150nm, which shows that the methanol diesel is a microemulsion.

[0072] Take 200mL of the methanol diesel and place it in a 250mL stoppered measuring cylinder, add 3mL of dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com