Optical cable, fiber reinforced plastics used thereby and preparation method thereof

A fiber reinforced plastic and optical cable technology, applied in the field of communication materials, can solve the problems of complex manufacturing process, large radius of curvature, and heavy texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

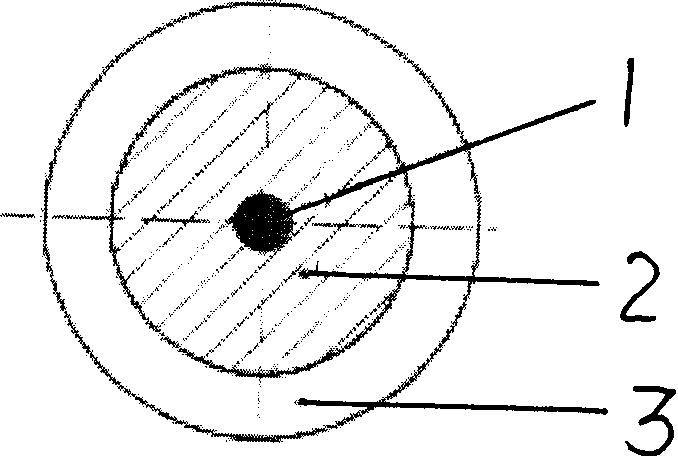

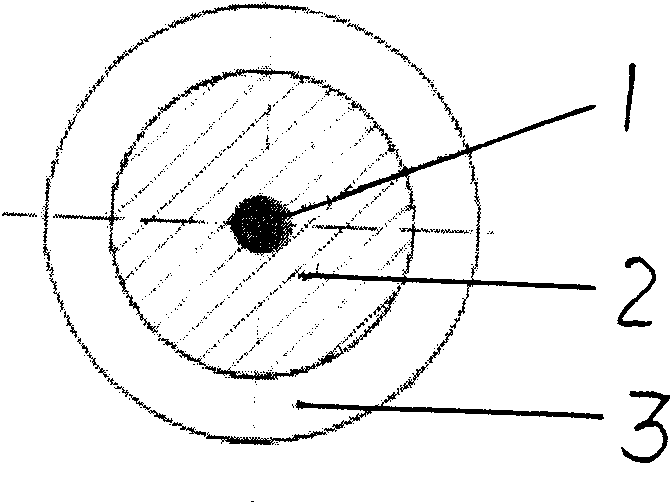

[0007] Embodiment 1: refer to figure 1 . According to the existing thermosetting and thermoplastic composite pultrusion technology, wrapping a reinforcing sheath on an optical fiber and wrapping a protective sheath outside the reinforcing sheath, and because the reinforcing sheath is made of fiber-reinforced plastic, the optical cable referred to in the present invention can be obtained.

Embodiment 2

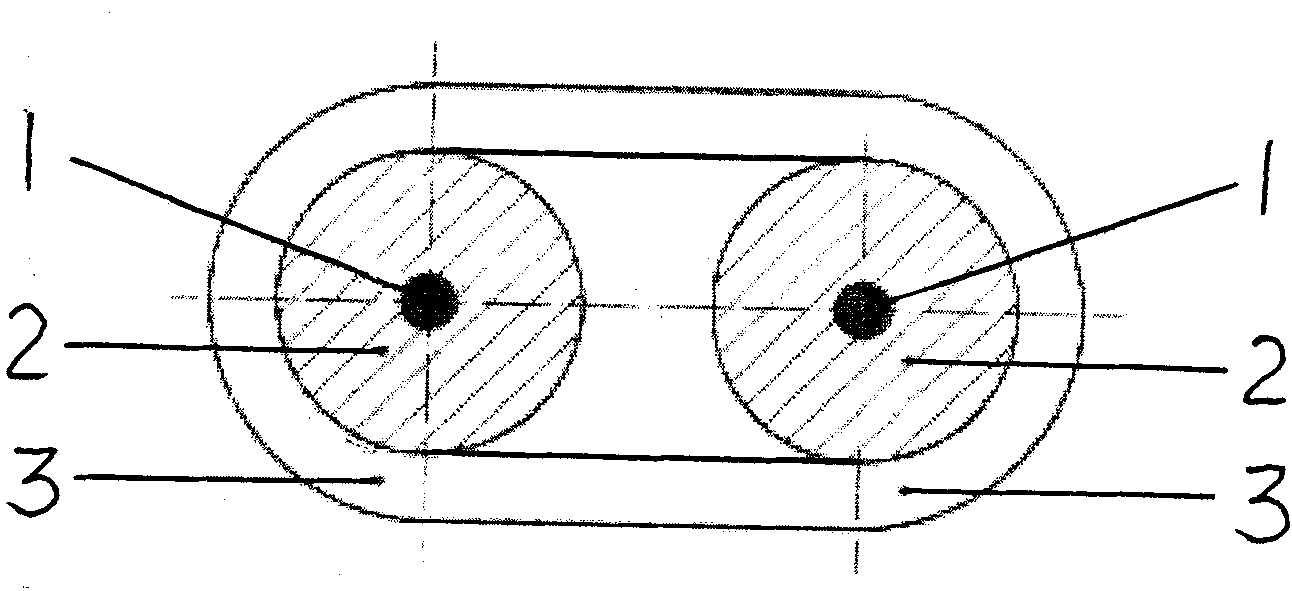

[0008] Embodiment 2: refer to figure 2 . According to the existing thermosetting and thermoplastic composite pultrusion technology, two (including more than two) optical fibers are respectively wrapped with a reinforcing sleeve and a protective sleeve is wrapped outside the reinforcing sleeve, and because the reinforcing sleeve is made of fiber-reinforced plastic, the invention can be obtained. called fiber optic cable.

Embodiment 3

[0009] Example 3: Take 13-25 kg of photocurable resin and 75-87 kg of fiber yarn, first put the photocurable resin into a constant temperature box at 70-90°C for 1-2 hours, then put the photocurable resin and fiber yarn into the solution Mix evenly in the tank, pultrude through a pultrusion die to form a shaped rod, place the shaped rod in an ultraviolet curing oven for 0.1 to 12 seconds to cure, and the fiber reinforced plastic referred to in the present invention can be obtained. In this embodiment, 20kg of photocurable resin and 80kg of fiber yarn are preferred. The photocurable resin is placed in a constant temperature box and the constant temperature is 80°C, and the constant temperature time is 1.5 hours. The curing time of the forming rod in the ultraviolet curing furnace is preferentially selected. 6 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com