Cylindrical microbiological fuel cell

A fuel cell and cylindrical technology, applied in the field of cylindrical microbial fuel cells, can solve the problems of high amplification cost and unfavorable operation mode, and achieve the effects of low cost, compact structure and good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

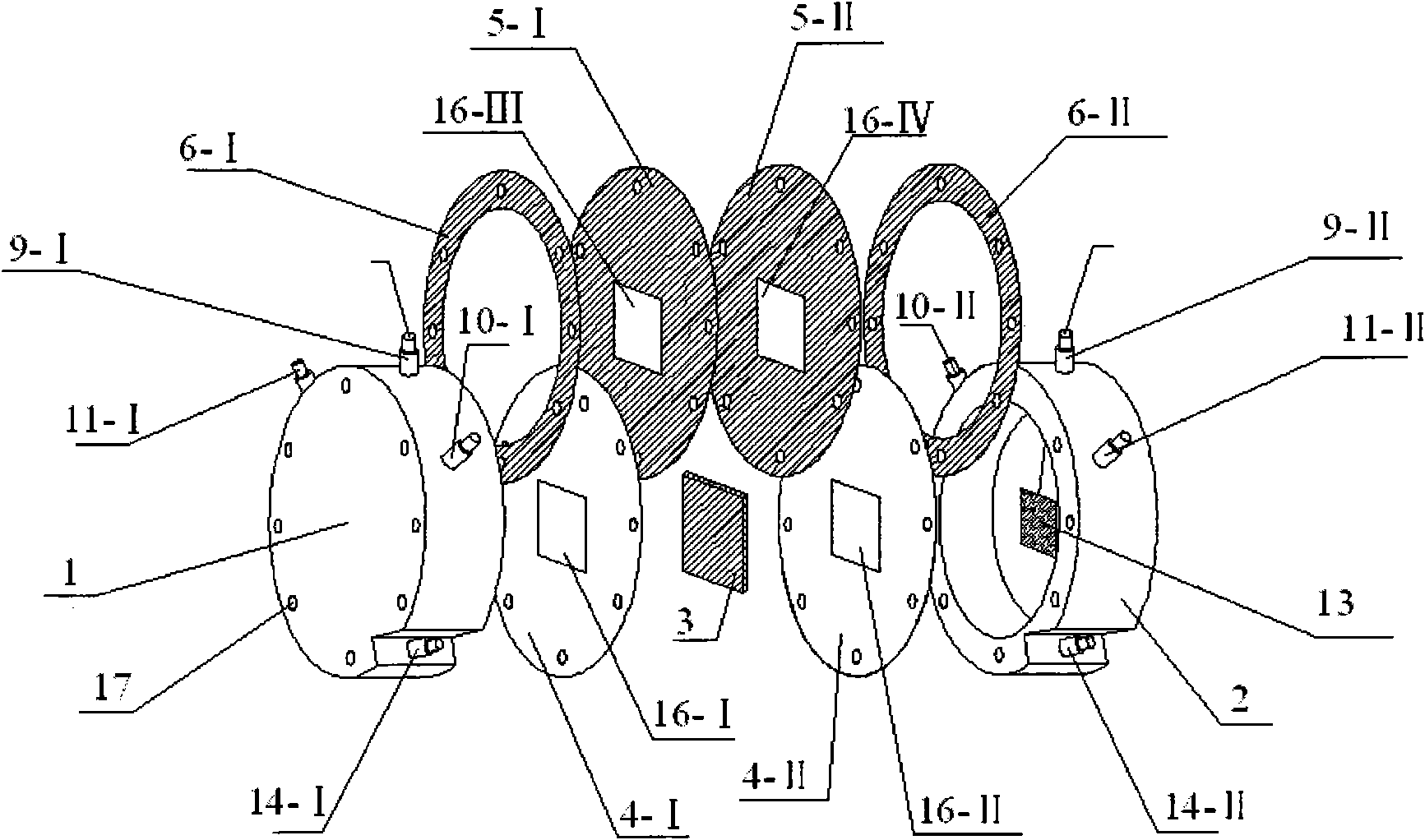

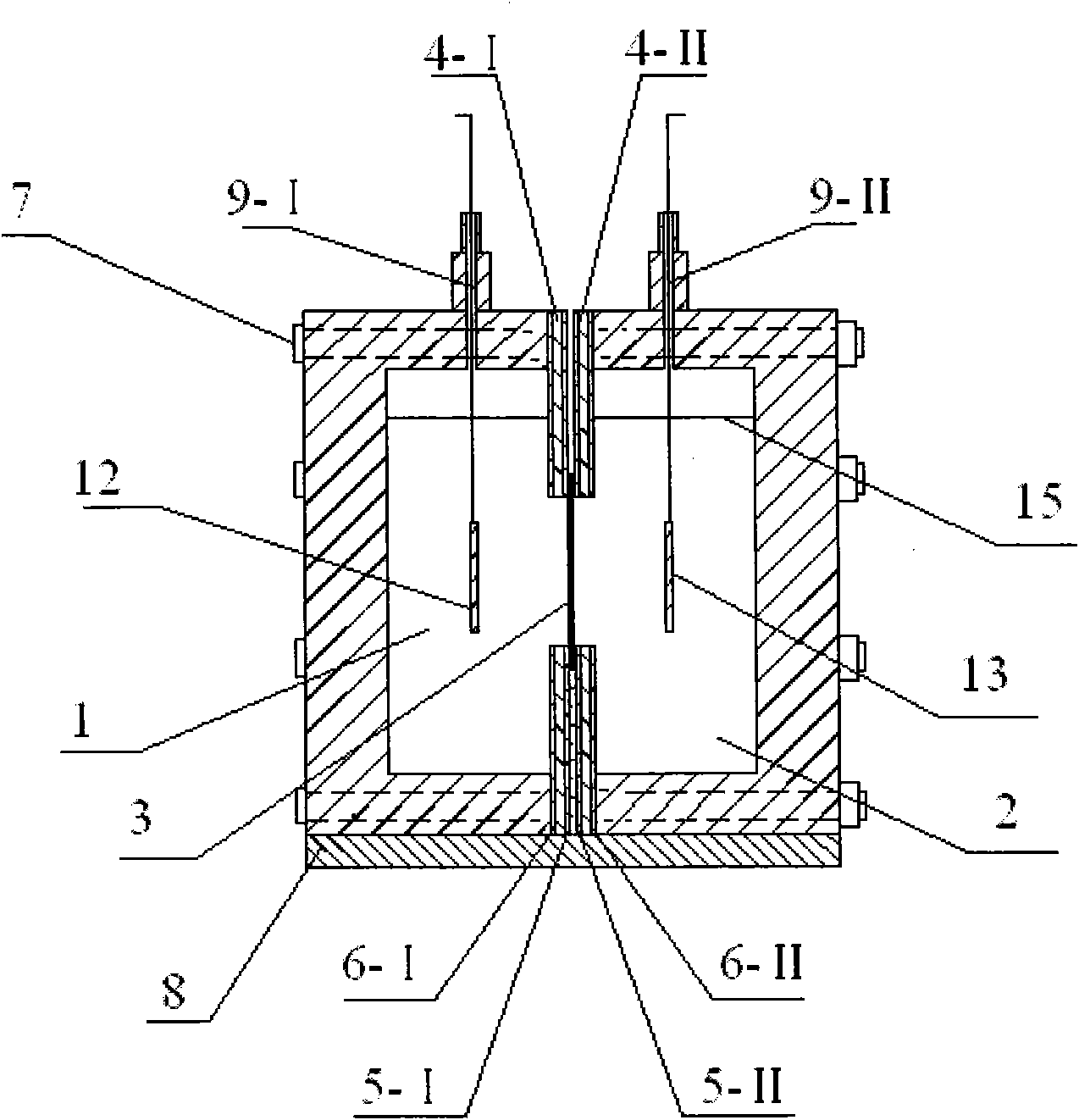

[0022] A cylindrical fuel cell is composed of an anode chamber 1, a cathode chamber 2, a proton membrane assembly, a silica gel gasket 6, a fastening bolt 7 and a base 8. Both the anode chamber 1 and the cathode chamber 2 are headed cylindrical structures. The cylinder part is the reaction chamber, and the upper parts of the cylinders of the anode chamber 1 and the cathode chamber 2 are respectively provided with electrode jacks 9-I, II, sampling holes 10-I, II with sealing plugs and exhaust holes 11-I , II, anode carbon paper 12 and cathode carbon paper 13 are respectively arranged in the anode reaction chamber and the cathode reaction chamber and are respectively drawn from the electrode jack 9-I, II sealing by wires, and the surface of the cathode carbon paper 13 is coated with a platinum catalyst. 1 and the bottom of the cylinder of the cathode chamber 2 are respectively provided with inlet holes 14-I and II which allow the airflow to enter the reaction chamber tangentially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com