Method for uniformly penetrating small-molecular emulsifier in instant rice grain

A technology of small molecule emulsifier and instant rice, applied in application, food preparation, food science and other directions, can solve the problems of incomplete penetration effect and insignificant anti-aging effect, and achieve slow aging rate, short time and rich nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

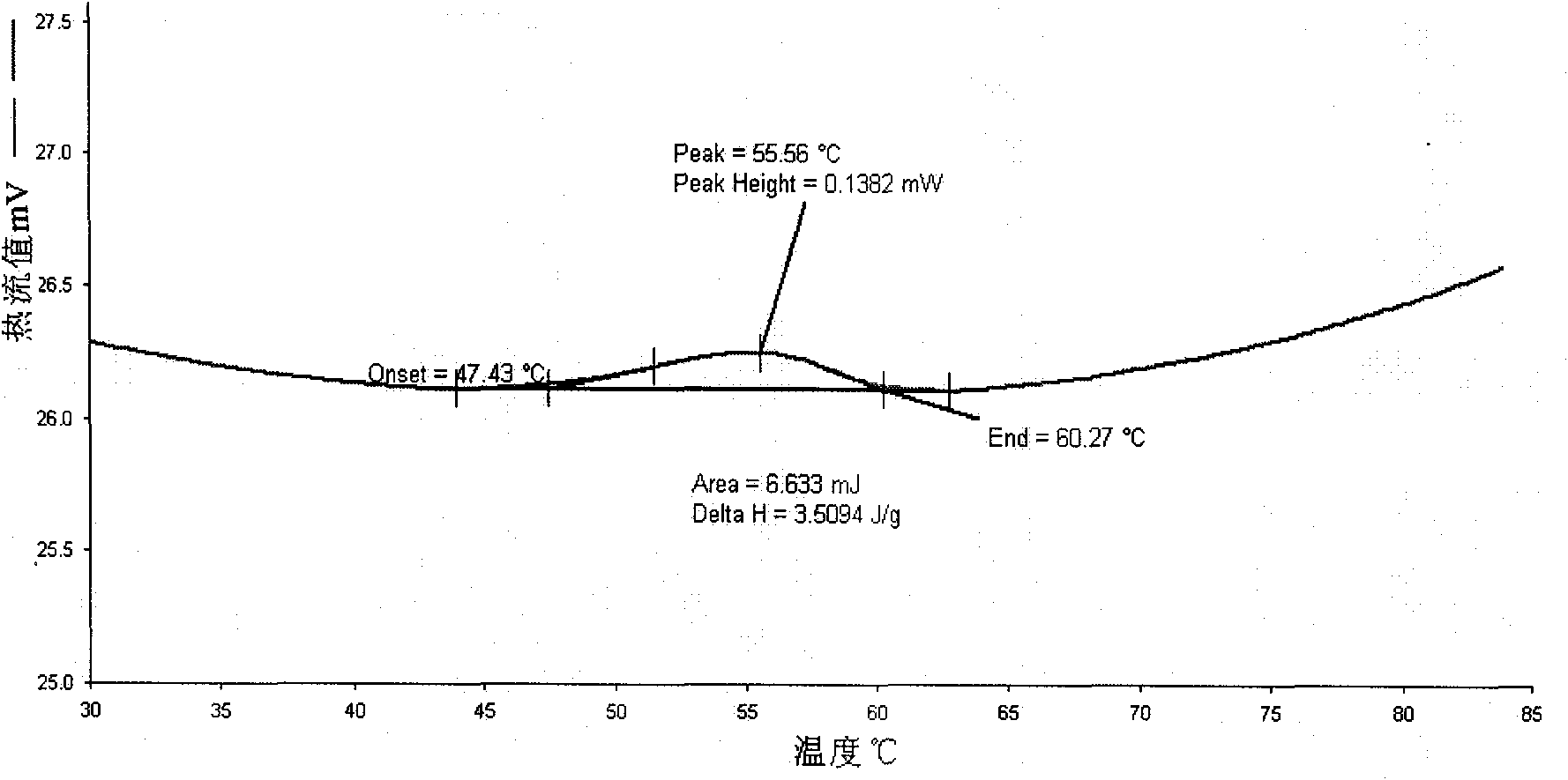

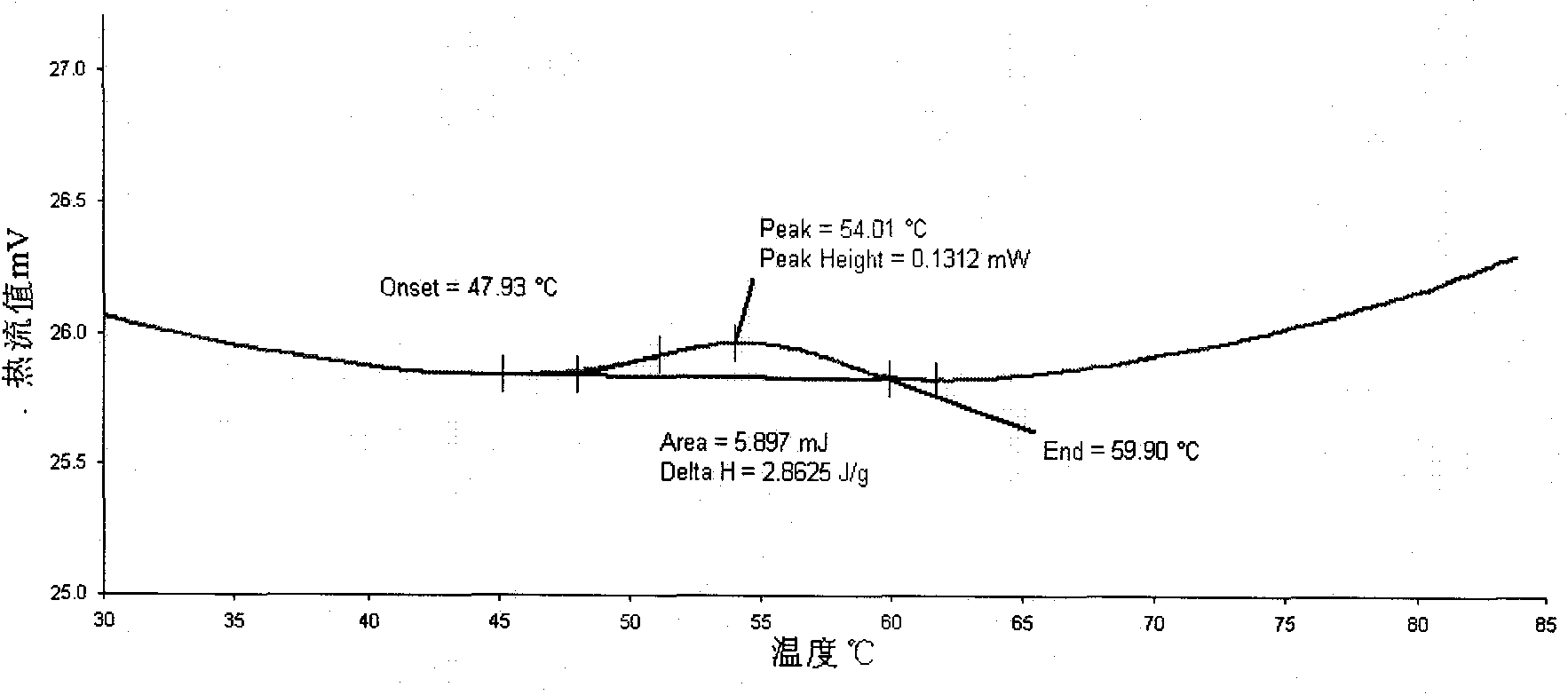

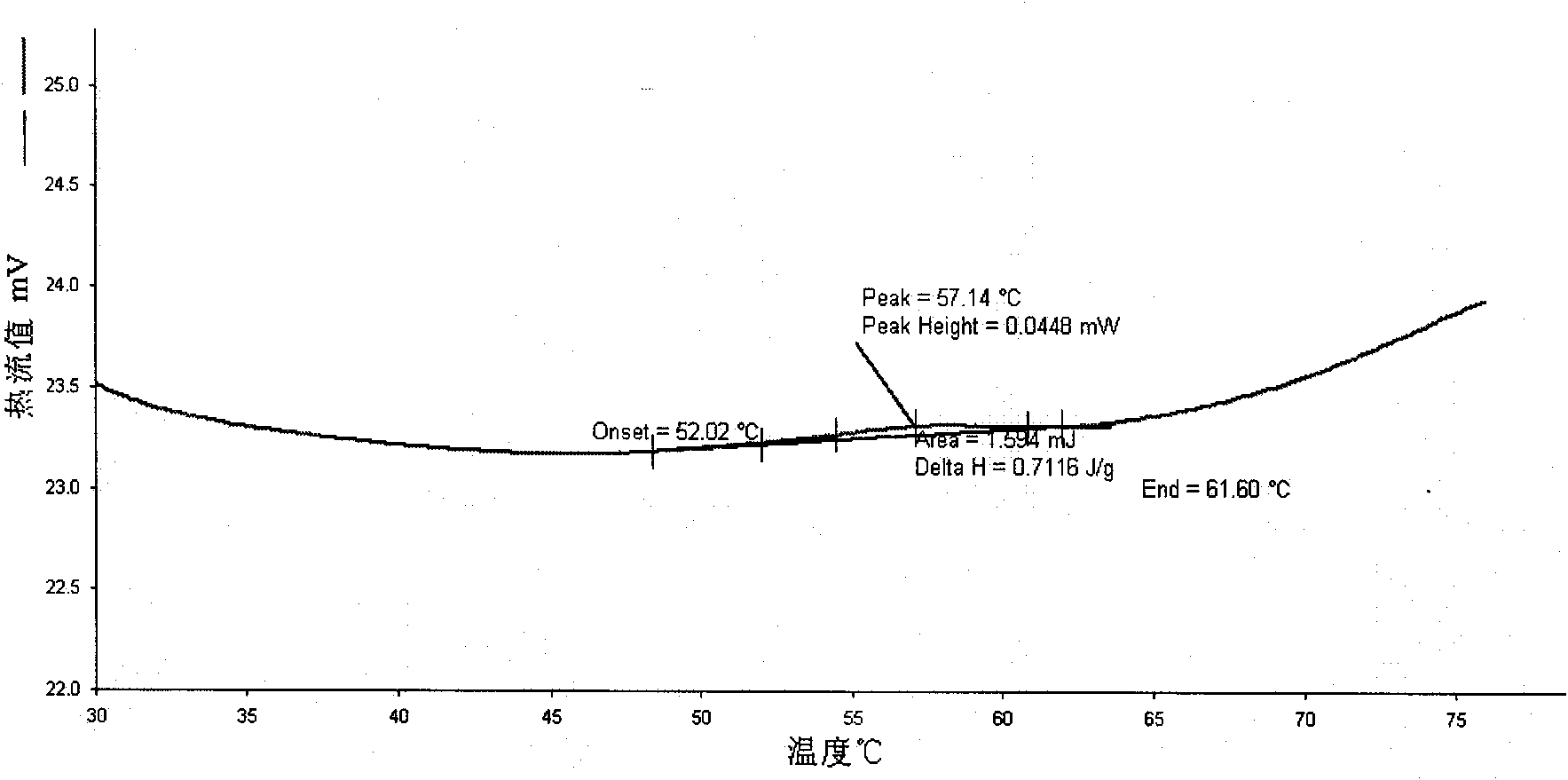

Image

Examples

Embodiment 1

[0018] A serving of instant rice: 75g of rice, wash, add monoglyceride and tap water to make the total weight 200g.

[0019] Weigh 75g of high-quality japonica rice into a vertical retort bag, wash it 3 times, add water and 0.3g of monoglyceride to make the total weight 200g (except the retort bag), vacuum pack it, and soak the rice at room temperature under a pressure of 600Mpa 10min, then raise the temperature to 100°C, and cook at 100°C for 15min. The obtained non-dehydrated instant rice has rich nutrition, good taste and slow aging rate, and is suitable for people who prefer hard rice.

Embodiment 2

[0021] A serving of instant rice: 75g of rice, wash, add β-cyclodextrin and tap water to make the total weight 225g.

[0022] Weigh 75g of high-quality rice (japonica rice 50g, glutinous rice 25g) in a vertical retort bag, wash 3 times, add water and 0.45g β-cyclodextrin to a total weight of 225g (excluding the retort bag), vacuum pack, At room temperature, soak the rice at 600Mpa for 8 minutes, then raise the temperature to 100°C, and cook at 100°C for 20 minutes. The obtained non-dehydrated instant rice has rich nutrition, good taste and slow aging rate, and is suitable for people who prefer soft rice.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com