Method for preparing high purity graphite

A high-purity graphite and high-purity technology, applied in the field of high-purity graphite preparation, can solve problems such as complex process flow, large safety hazards, and low safety, and achieve the effects of simple process operation, high utilization value, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

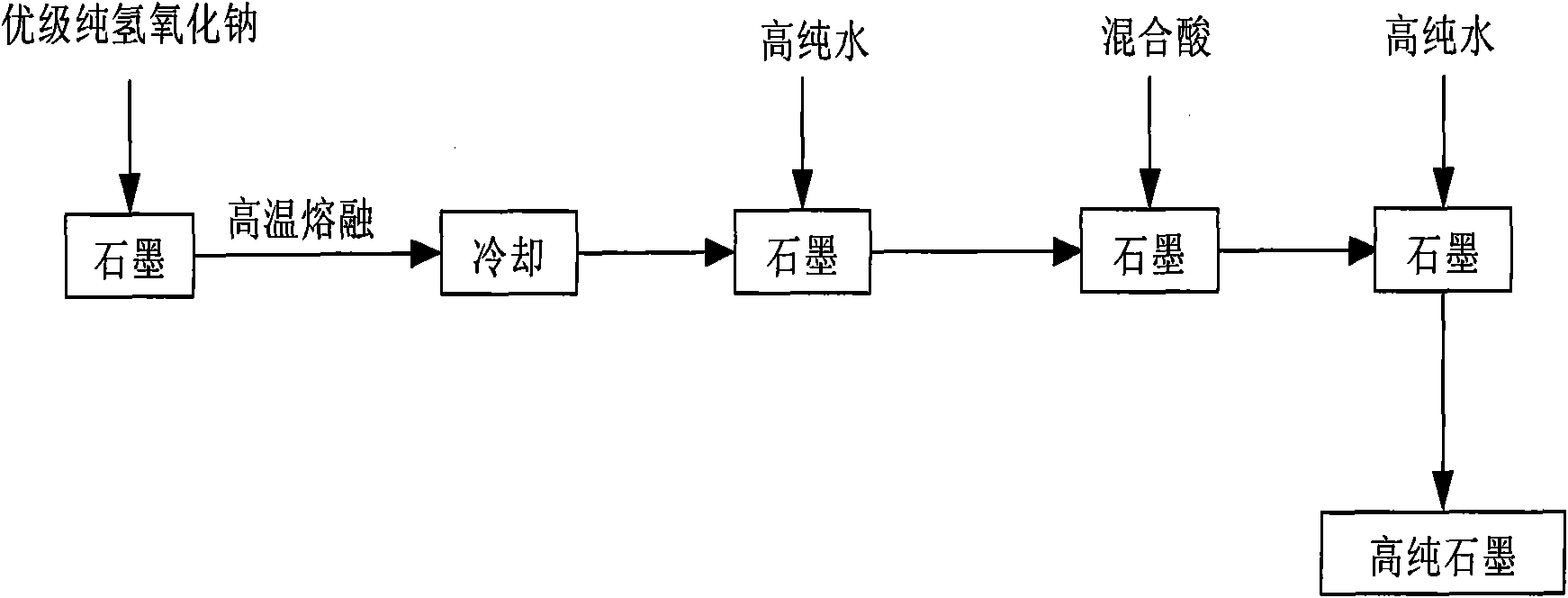

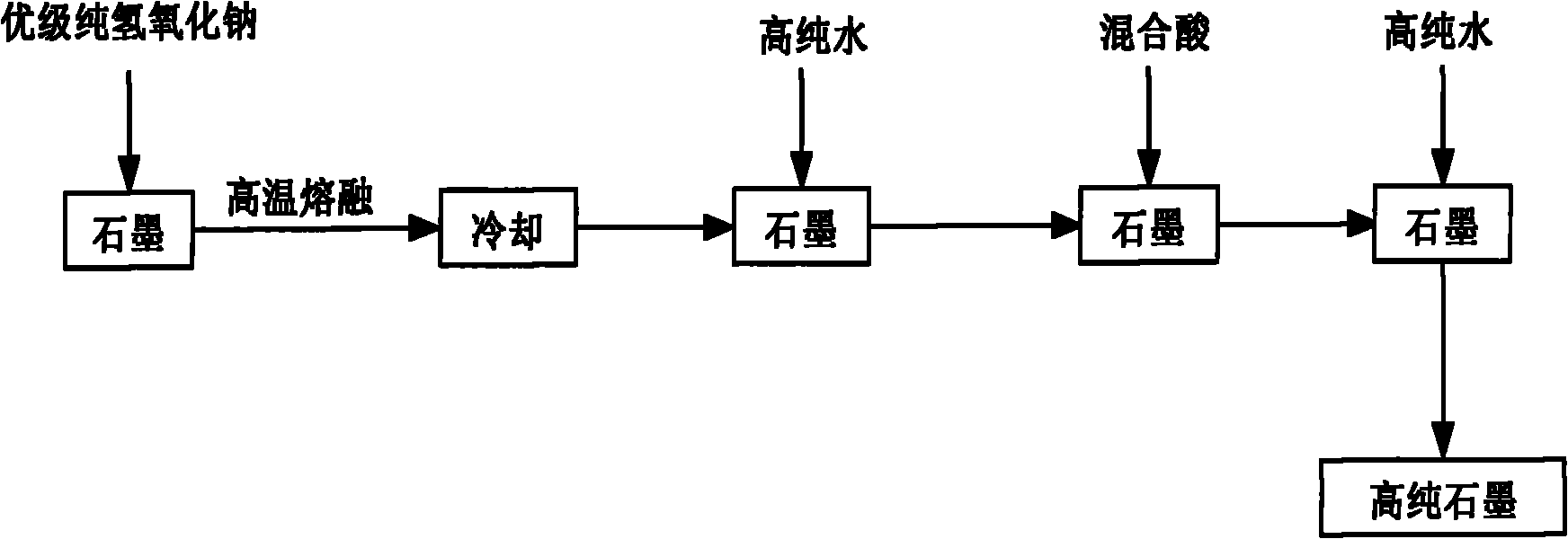

Image

Examples

Embodiment 1

[0020] Weigh high-grade pure sodium hydroxide, add high-purity water to stir and dissolve, then take high-purity flake graphite with a fixed carbon content of 99.9% by mass percentage 10% (that is, the amount of sodium hydroxide is 10wt% of the graphite amount), and add it to the hydrogen storage In a beaker of sodium oxide solution, mix and stir, melt at a temperature of 500°C for 2 hours, filter under low pressure after cooling, and wash with water 5-8 times until the pH of the filtrate is 6.5. Mix the hydrofluoric acid and hydrochloric acid solutions of the same concentration (10%) and the same volume, and add them to the polytetrafluoroethylene beaker together with the high-purity graphite after melting according to the liquid-solid ratio of 5:1, stirring at a rate of 500r / min at room temperature Under the reaction for 3 hours, the reacted material is filtered with low pressure and high-purity water for 5-8 times until the pH of the filtrate reaches 6.5;

[0021] Put the o...

Embodiment 2

[0023] Weigh high-grade pure sodium hydroxide, add high-purity water and stir to dissolve, then weigh high-purity graphite with a fixed carbon content of 99.9% according to 15% by mass, add it to a beaker containing sodium hydroxide solution, mix the slurry and stir, at a temperature of 600°C Melted for 2 hours, cooled and washed with low-pressure water for 6-8 times until the pH of the filtrate was 6.5. Mix hydrofluoric acid with a concentration of 20% and hydrochloric acid solution with a concentration of 10% in equal volumes, and add them to a polytetrafluoroethylene beaker together with the molten high-purity graphite at a liquid-solid ratio of 7:1, with a stirring rate of 500r / min at room temperature React for 3 hours, filter the reacted material with low-pressure filter, high-purity water for 6-8 times until the pH of the filtrate reaches 6.5;

[0024] Put the obtained high-purity graphite filter cake into a blast oven, dry it at 110°C, grind it, and pack it into a bag f...

Embodiment 3

[0026] Weigh high-grade pure sodium hydroxide, add high-purity water and stir to dissolve, then weigh high-purity graphite with a fixed carbon content of 99.9% according to 15% by mass, add it to a beaker containing sodium hydroxide solution, mix the slurry and stir, and heat it at a temperature of 650°C Melted for 5 hours, cooled and washed with low-pressure water for 6-8 times until the pH of the filtrate was 6.5. Mix hydrofluoric acid with a concentration of 25% and dilute hydrochloric acid with a concentration of 10% in a volume ratio of 1:3, and add them to a polytetrafluoroethylene beaker with a liquid-solid ratio of 8:1 and high-purity graphite after melting, and the stirring rate is 500r / min, react at a temperature of 40°C for 4 hours, filter the reacted material with low-pressure filtration, and continue washing with high-purity water for 7-8 times until the pH of the filtrate reaches 6.5;

[0027] Put the obtained high-purity graphite filter cake into a blast oven, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com