Work layer coating of steel casting tundish

A tundish and working layer technology, applied in the field of working layer coatings, can solve the problems of short service life, flexural resistance, compressive strength and high temperature performance of the tundish, which cannot effectively meet the requirements of the tundish, and achieve the ability to resist molten steel erosion , high-temperature performance, and the effect of increasing the flexural and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The working layer paint of the iron and steel foundry tundish described in this embodiment, it is made up of following raw material proportioning by weight:

[0022] Forsterite 64 parts;

[0023] 31.5 parts of sintered magnesia;

[0024] 2.5 parts of silica powder;

[0025] 1 part paper fiber;

[0026] 0.5 part of sodium tripolyphosphate;

[0027] 0.3 parts of yellow dextrin;

[0028] 0.2 parts of white mud;

[0029] Explosion-proof fiber 0.01 parts;

[0030] 0.0013 parts of sodium dodecylsulfonate;

[0031] Aluminum powder 0.001 parts.

[0032] The production process of the coating for the working layer of the iron and steel casting tundish described in this embodiment is: after weighing each raw material according to the above ratio, first mix forsterite and sintered magnesia in a planetary mixer for 7 minutes, and then mix the The remaining substances were added into a planetary mixer and mixed for 5 minutes to obtain a finished coating, which was weighed and...

Embodiment 2

[0037] In the coating for the working layer of the iron and steel casting tundish described in this embodiment, the sintered magnesia is 180 mesh 92 sintered magnesia;

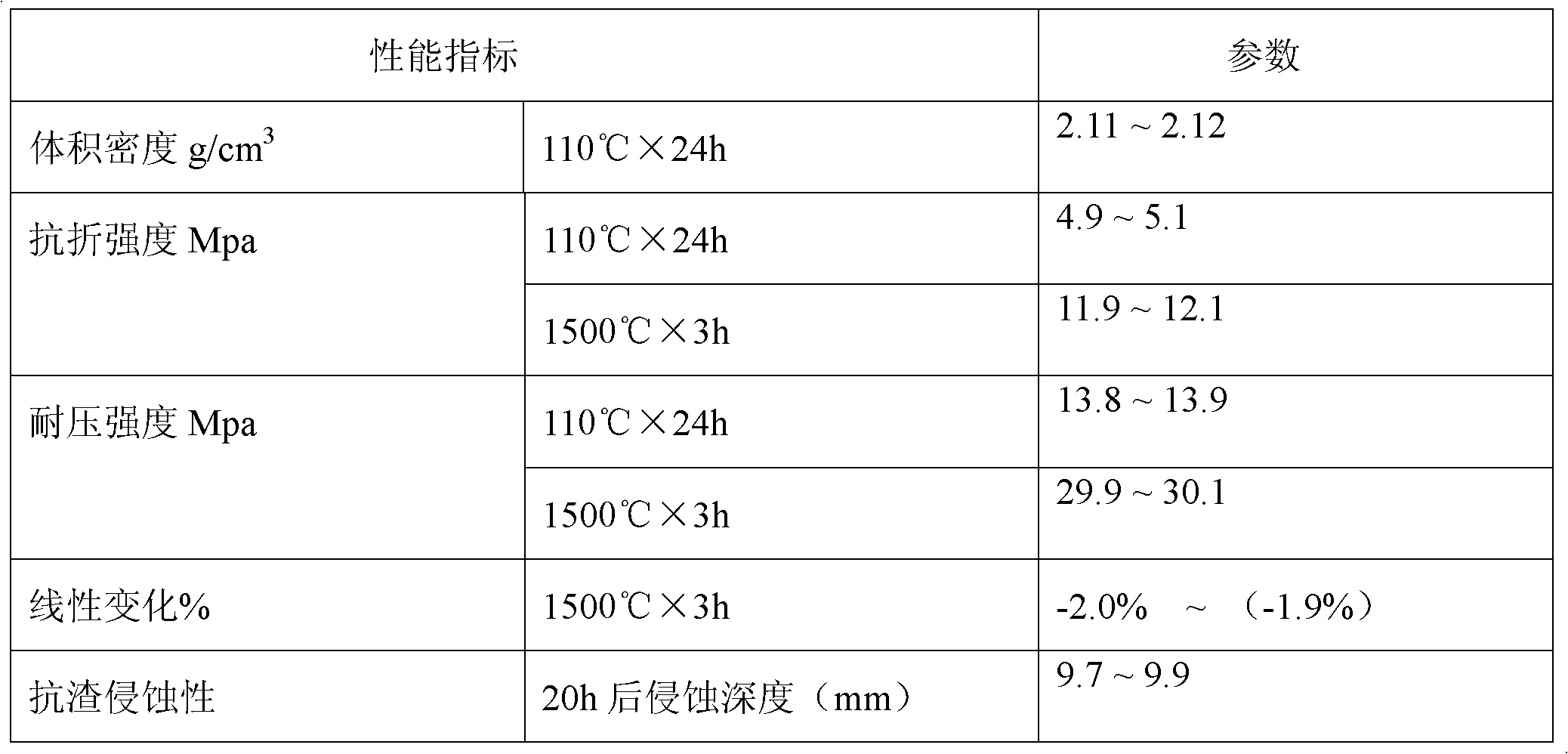

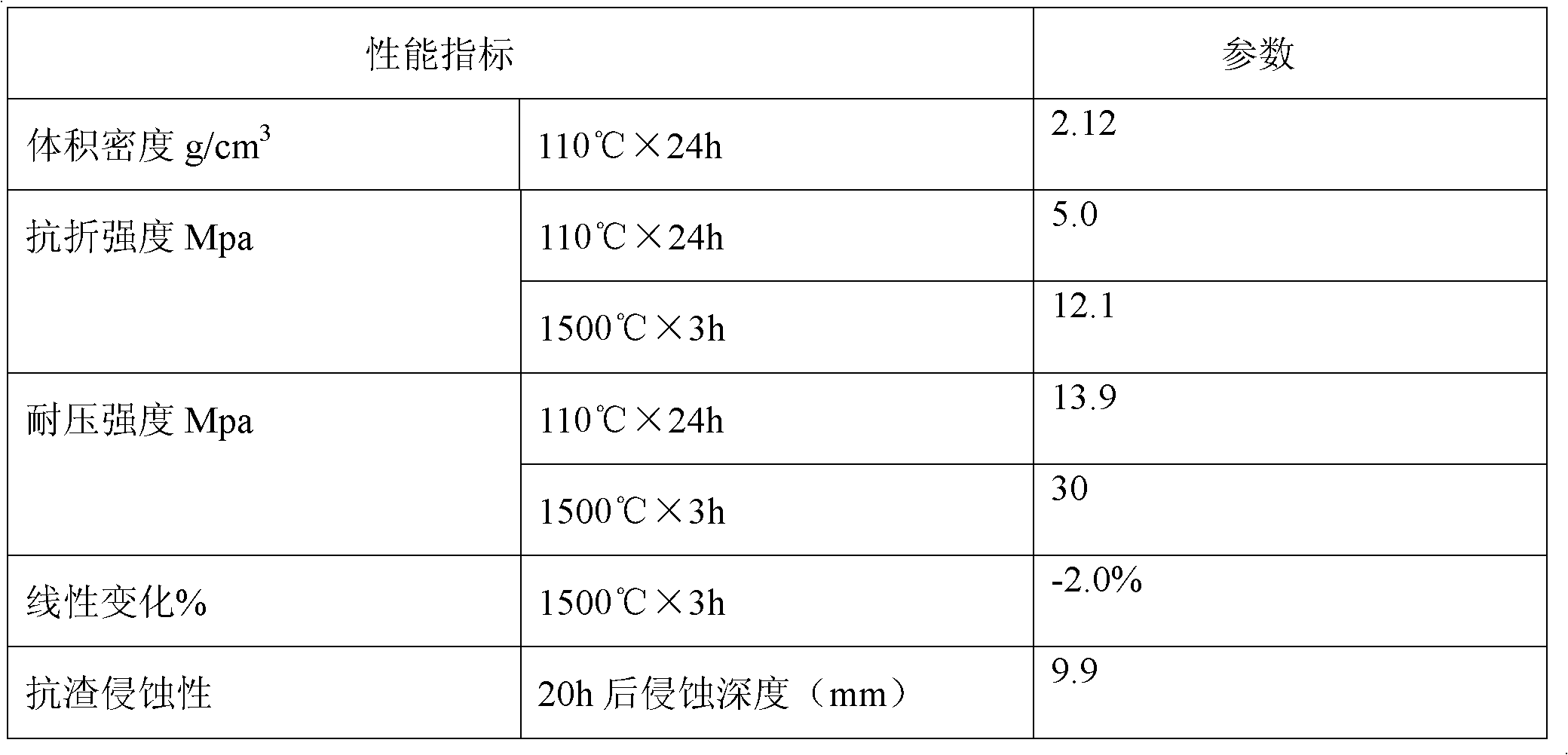

[0038] The performance (actual measurement) of the working layer coating of the iron and steel foundry tundish described in this embodiment is as follows:

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com