Preparation method and device of organic soil conditioner

A preparation device, a technology of organic soil, applied in the field of agricultural soil and fertilizer, to achieve the effect of fertilizing soil fertility and promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

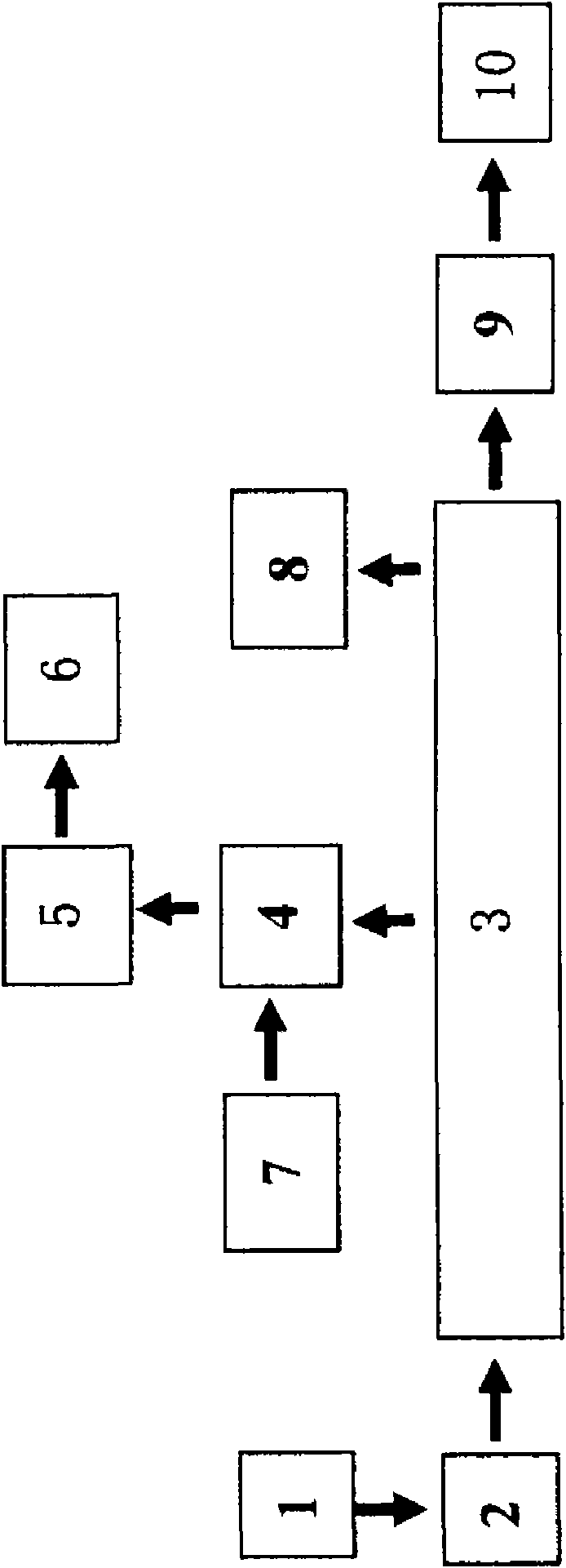

[0030] Please combine figure 1 , the preparation method of the present invention, its main steps are:

[0031] a) Heat the temperature in the heating chamber of the intermittent rotary preparation device to 200°C-300°C, and rotate the large drum, the small drum, and the small discharge drum of the intermittent rotary preparation device in a clockwise direction as viewed from one end of the gas collection chamber;

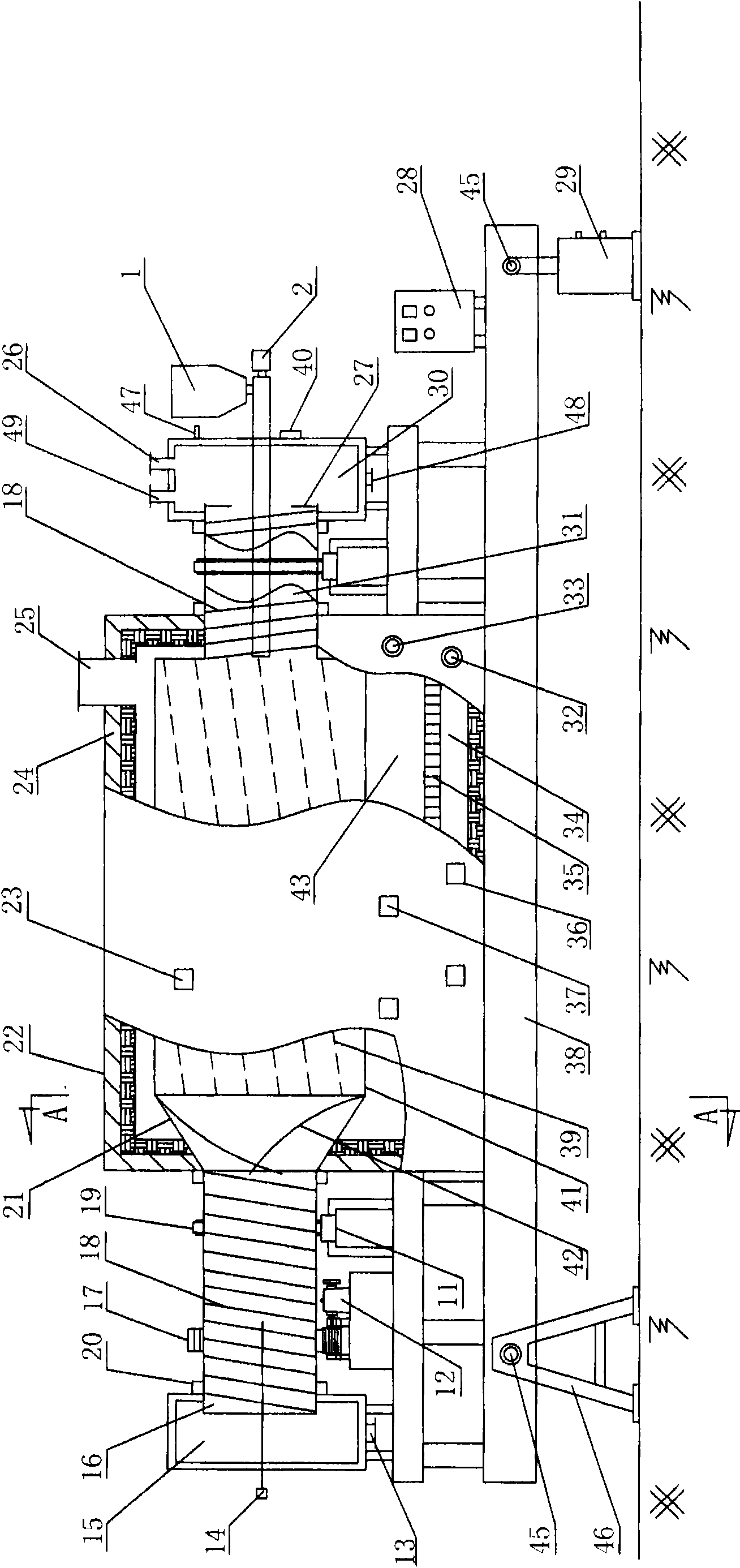

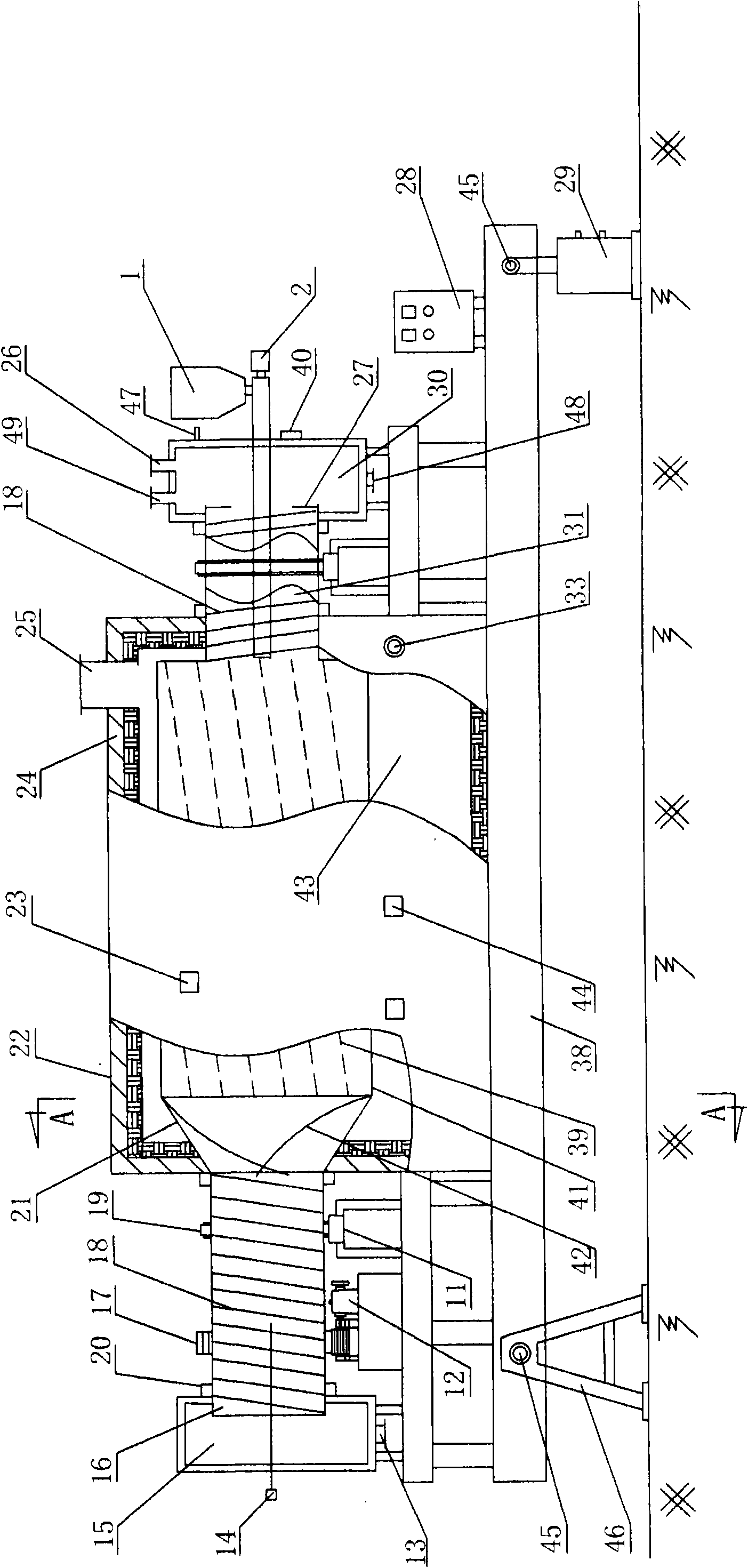

[0032] b) Use a hydraulic lifting device to adjust the inclination angle of the overall steel base 38 to 1-3°, turn the screw conveyor, and transport the sludge in the sludge bin from one end of the air collection chamber to the large drum, and then enter the sludge in the large drum The large drum is tilted and rotated and the turning plate moves forward to cover the bottom wall of the large drum, and then use the hydraulic lifting device to adjust the inclination angle of the integral steel base 38 to 0°, open the valve of the steam outlet on the top of the air co...

Embodiment 1

[0048] The organic soil conditioner 10 is prepared by using sludge from a sewage treatment plant with a water content lower than 85% as raw material and gas as fuel. Before the sludge is prepared as an organic soil conditioner10, it should be tested whether the heavy metals in the sludge meet the relevant national standards.

[0049] see figure 1 , is a schematic diagram of the preparation process of the organic soil amendment;

[0050] a) Heat the temperature in the heating chamber 43 of the intermittent rotary preparation device 3 to the dehydration temperature (200°C-300°C), and place the large drum 41, the small drum 31, and the small discharge drum 16 of the intermittent rotary preparation device 3 Viewed from one end of the gas collection chamber 30, rotate clockwise;

[0051] b) Use the hydraulic lifting device 29 to adjust the inclination angle of the integral steel base 38 to 3°, turn the screw conveyor 2, and transport the sludge in the sludge bin 1 from one end of...

Embodiment 2

[0086] Using the sludge and algae organisms in the process of dredging the bottom of the lake with a water content lower than 85% as raw materials and using coke as fuel to prepare an organic soil conditioner 10

[0087] Before the sludge and algae organisms in the lake bottom dredging process were prepared, the heavy metals in the sludge were tested to meet the relevant national standards.

[0088] see figure 1 , is a schematic diagram of the preparation process of the organic soil amendment;

[0089] a) Heat the temperature in the heating chamber 43 of the intermittent rotary preparation device 3 to the dehydration temperature (200°C-300°C), and place the large drum 41, the small drum 31, and the small discharge drum 16 of the intermittent rotary preparation device 3 Viewed from one end of the gas collection chamber 30, rotate clockwise;

[0090] b) Use the hydraulic lifting device 29 to adjust the inclination angle of the integral steel base 38 to 3°, turn the screw conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com