Method for enhancing fermentation yield of ansamycin

A technology of increasing production and ansamycin, applied in the field of bioengineering, can solve the problems of complex medium components, difficult research mechanism, uncertain components, etc., and achieve the effect of convenient large-scale production, high fermentation level and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The strain used: Actinosynnema pretiosum ATCC31565, which was purchased from the American Standard Biological Collection (ATCC) in Rockefeller, Maryland, USA.

[0028] Seed culture: The ingredients of the seed medium are 0.4% of yeast extract, 1% of maltose, and 0.4% of glucose. Glycerol tubes are inoculated in primary seed medium, cultured at 25-32°C for 24-60h, inoculated with 1.0-3.0% inoculation amount in secondary seed medium, and cultured at 25-32°C for 24-60h.

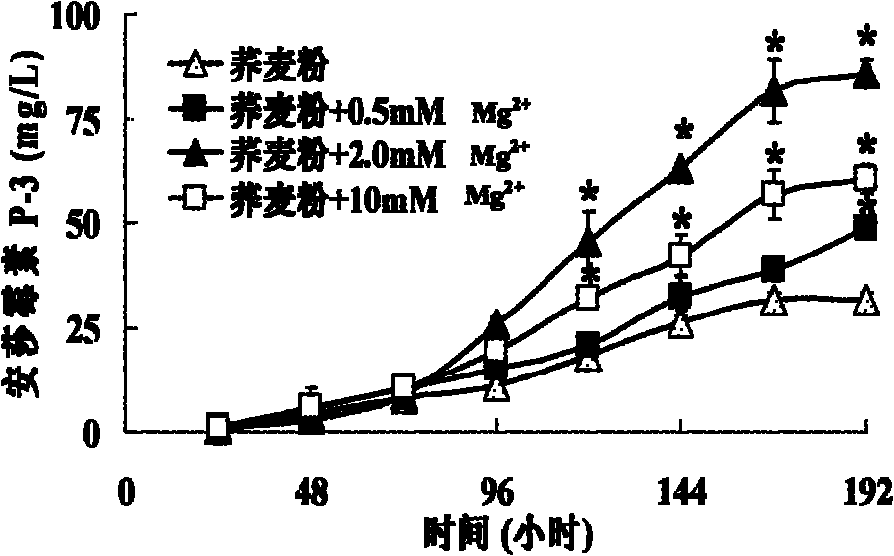

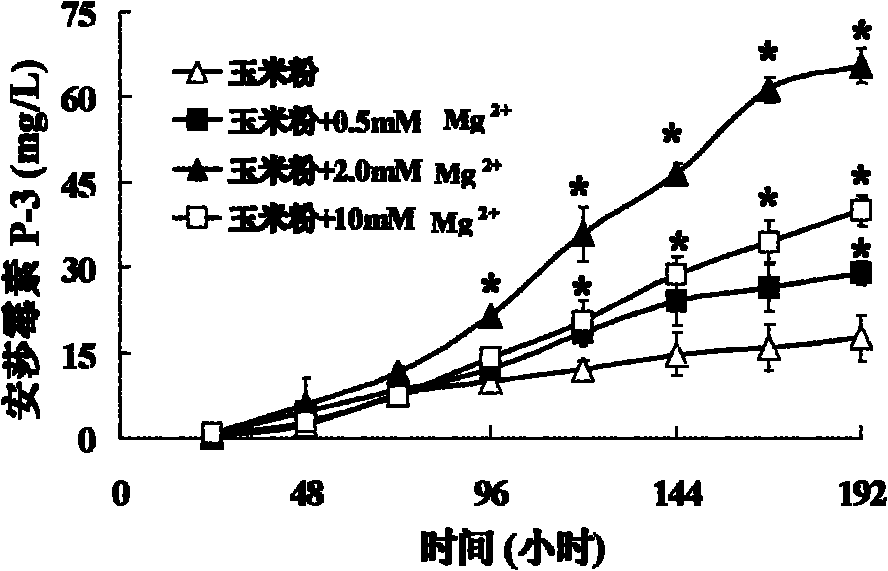

[0029] Fermentation culture: fermentation medium is yeast extract 1%, corn flour filtrate 2%, glucose 0.5%, glycerin 4%, dipotassium hydrogen phosphate 0.05%, heptahydrate and ferrous sulfate 0.0002%, calcium carbonate 0.5%, and then configure 1M magnesium sulfate aqueous solution is added to the above fermentation broth for fermentation, and the concentration of magnesium ions put into the shake flask is 0.1-20mM. 1.0-3.0% inoculation amount is inoculated in a fermentation shaker flask, fermented at 150...

Embodiment 2

[0033] The bacterial classification that adopts: with embodiment 1;

[0034] Seed culture: with embodiment 1;

[0035] Fermentation culture: Same as in Example 1, the corn flour filtrate was changed to buckwheat flour filtrate, a certain amount of magnesium ion solution was added to the initial material for fermentation, and the magnesium ion concentration after being put into the shake flask was 0.1-20mM. ;

[0036] Sample processing and detection method: the same as in Example 1.

[0037] Such as figure 2 As shown, the results show that when different concentrations of magnesium ions are added, the ansamycin production is greatly improved compared with the control. When the concentration of magnesium ions is 2mM, the effect is the best, up to 85mg / L, compared with the control Ratio increased by nearly 3 times.

Embodiment 3

[0039] The bacterial classification that adopts: with embodiment 1;

[0040] Seed culture: with embodiment 1;

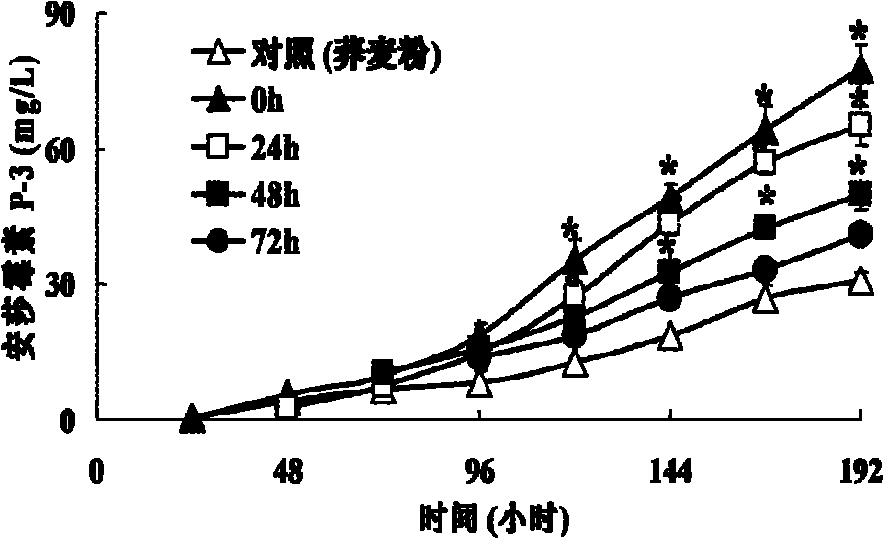

[0041] Fermentation culture: same as in Example 1, adding 2mM magnesium ions at 0, 24, 48, and 72 hours respectively.

[0042] Sample processing and detection method: the same as in Example 1.

[0043] Such as image 3 As shown, the results show that the effect of adding magnesium ions is the most significant at 0h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com