Maintenance method of blast furnace liner

A blast furnace lining and blast furnace technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as low cost, achieve short construction period, high maintenance efficiency, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

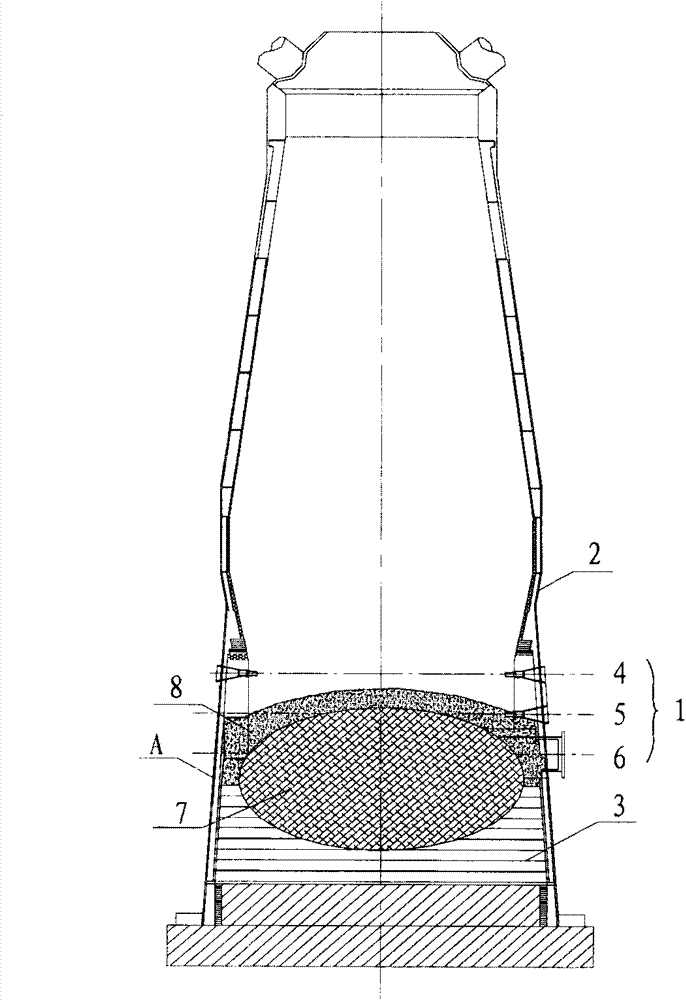

[0022] figure 1 A schematic cross-sectional view of a blast furnace with an eroded lining. refer to figure 1 , the inner shape of the blast furnace includes: a hearth 1, a bosh 2, a furnace waist, a furnace shaft and a furnace throat, and the furnace bottom 3 is located below the hearth 1. The tuyere 4, the slag port 5 and the iron port 6 are all formed on the hearth 1, the tuyere 4 is used to blow in oxygen-enriched air and coal powder, the slag port 5 and the iron port 6 are respectively used to transfer the slag and molten iron generated in the blast furnace from discharged from the furnace. Such as figure 1 As shown, due to long-term erosion, a residual iron layer 7 is formed in the hearth 1 and erodes the multi-layer refractory bricks constituting the furnace bottom 3 . Above the residual iron layer 7 is a coke layer 8 .

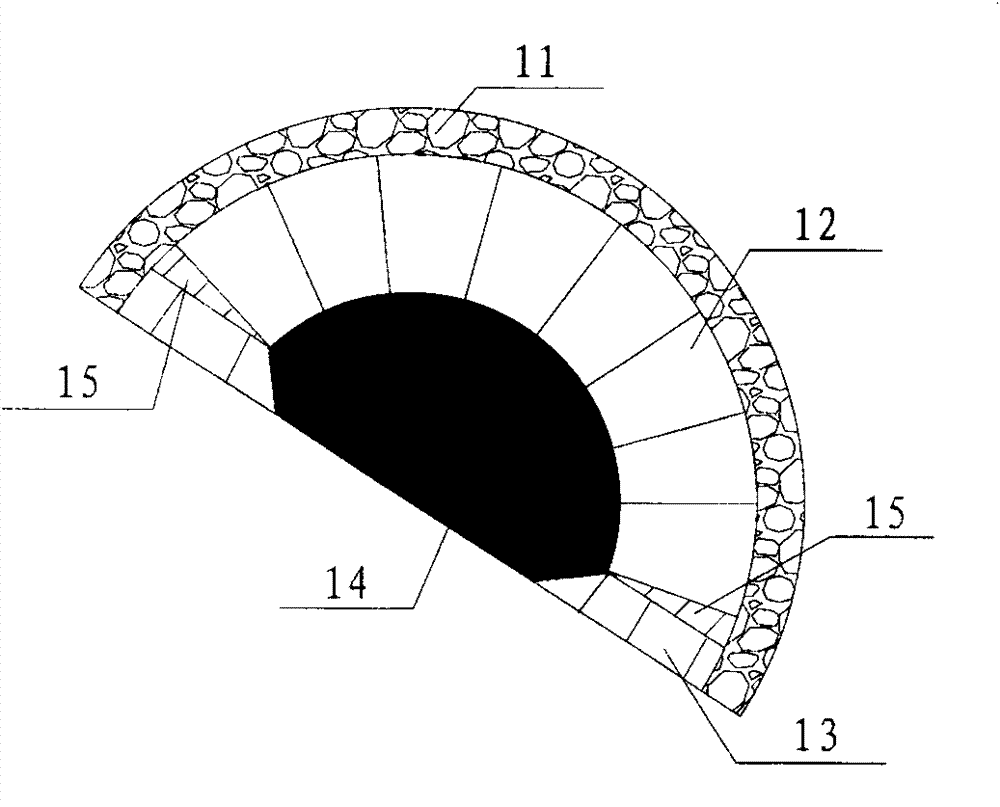

[0023] figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com