Novel austenitic heat-resistance stainless steel

A technology of heat-resistant stainless steel and austenite, which is applied in the field of alloy steel, can solve problems such as component damage, alloy failure, and grain boundary segregation, and achieve the effects of improving economic benefits, reducing component consumption, and reducing embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

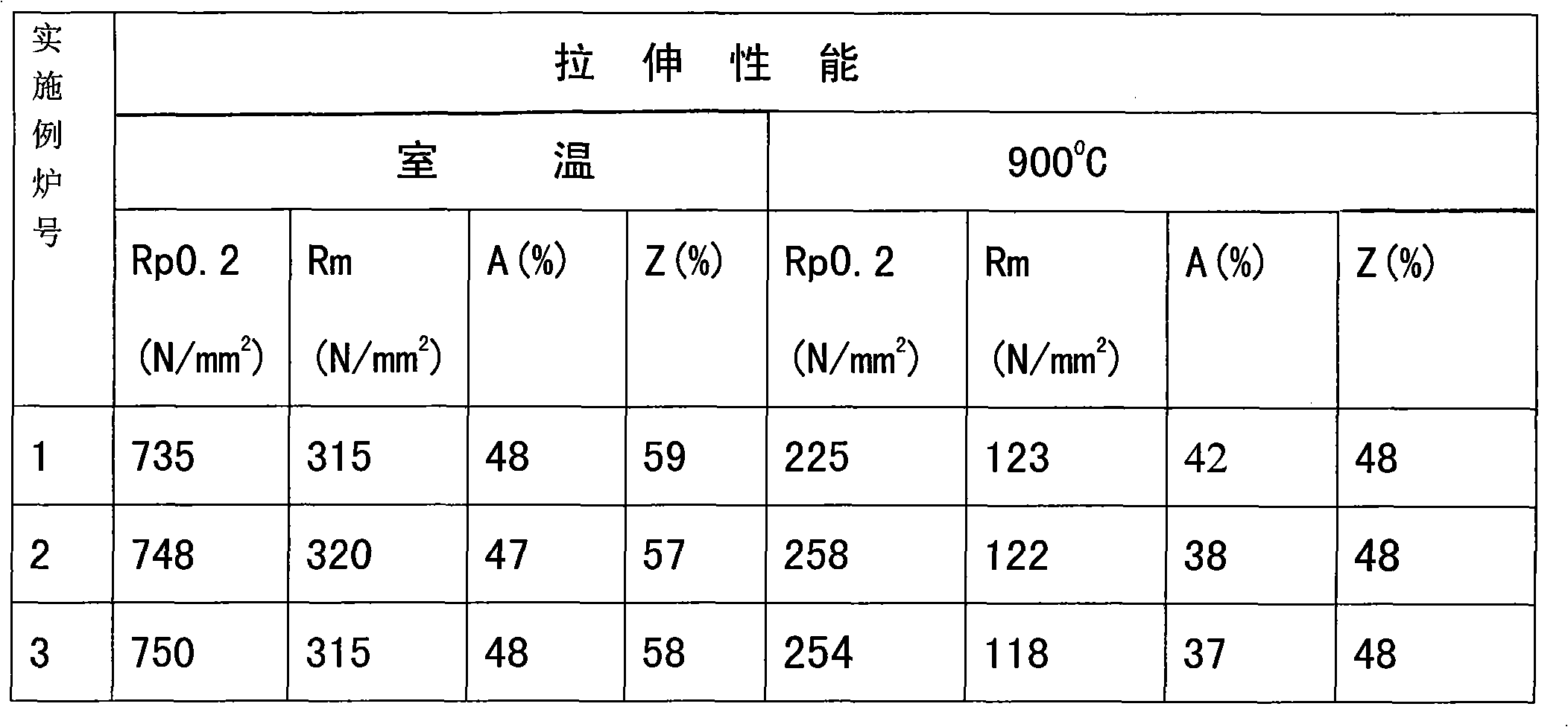

[0068] 1. Mechanical property test

[0069]

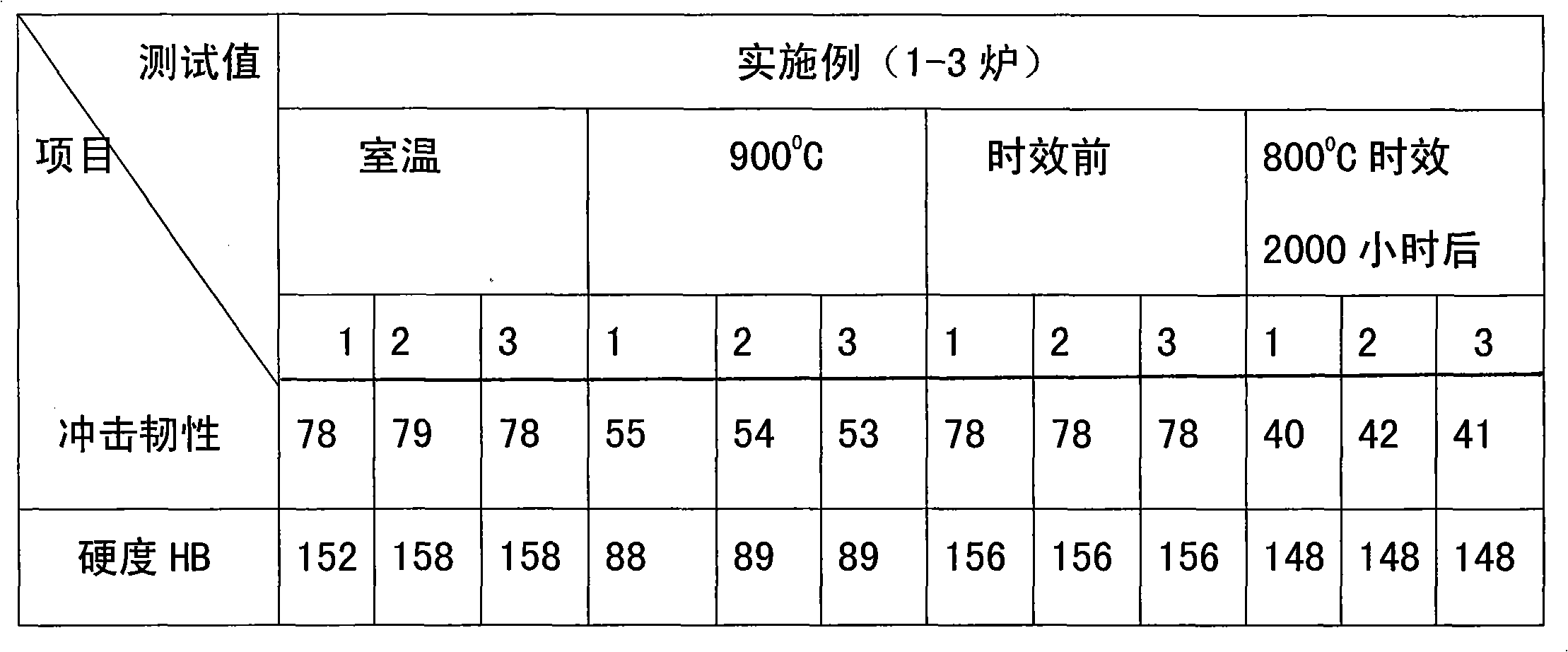

[0070] 2. Impact toughness, hardness

[0071]

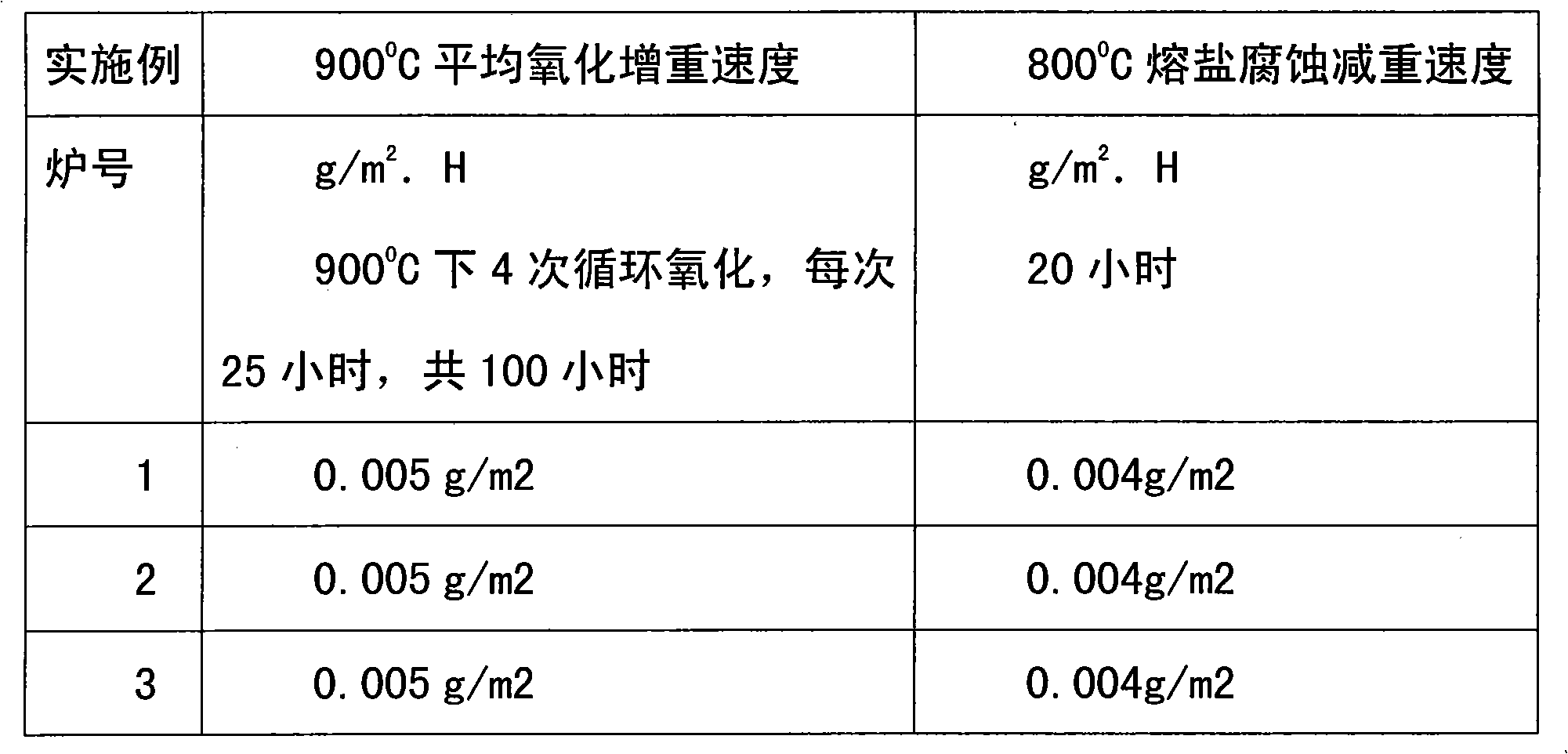

[0072] 3. Oxidation weight gain rate and corrosion weight loss rate in molten salt

[0073]

[0074] Test results: According to the analysis of the measurement situation of the austenitic heat-resistant stainless steel trial production piece, the above-mentioned austenitic heat-resistant stainless steel 314 (the present invention) meets the requirements of parts such as engines, steam boilers, steam turbines, ethylene cracking furnaces and ammonia conversion furnaces. The use requirements of the item, the manufacturing process of the product is stable.

[0075] Through the above examples and mechanical performance testing, the austenitic heat-resistant stainless steel designed by the present invention has reasonable composition design, stable manufacturing process, excellent high-temperature strength and plasticity suitable for it, and high high-temperature oxidation resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com