Method for calibrating distance between scan lines of scanning electron microscope by utilizing moires

A scanning electron microscope and scanning line technology, applied in the field of photomechanics, can solve the problems of inability to meet high-precision measurement, not considering working distance, measurement accuracy changes, etc., and achieve the effects of high precision, real-time in-situ calibration, and high measurement sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

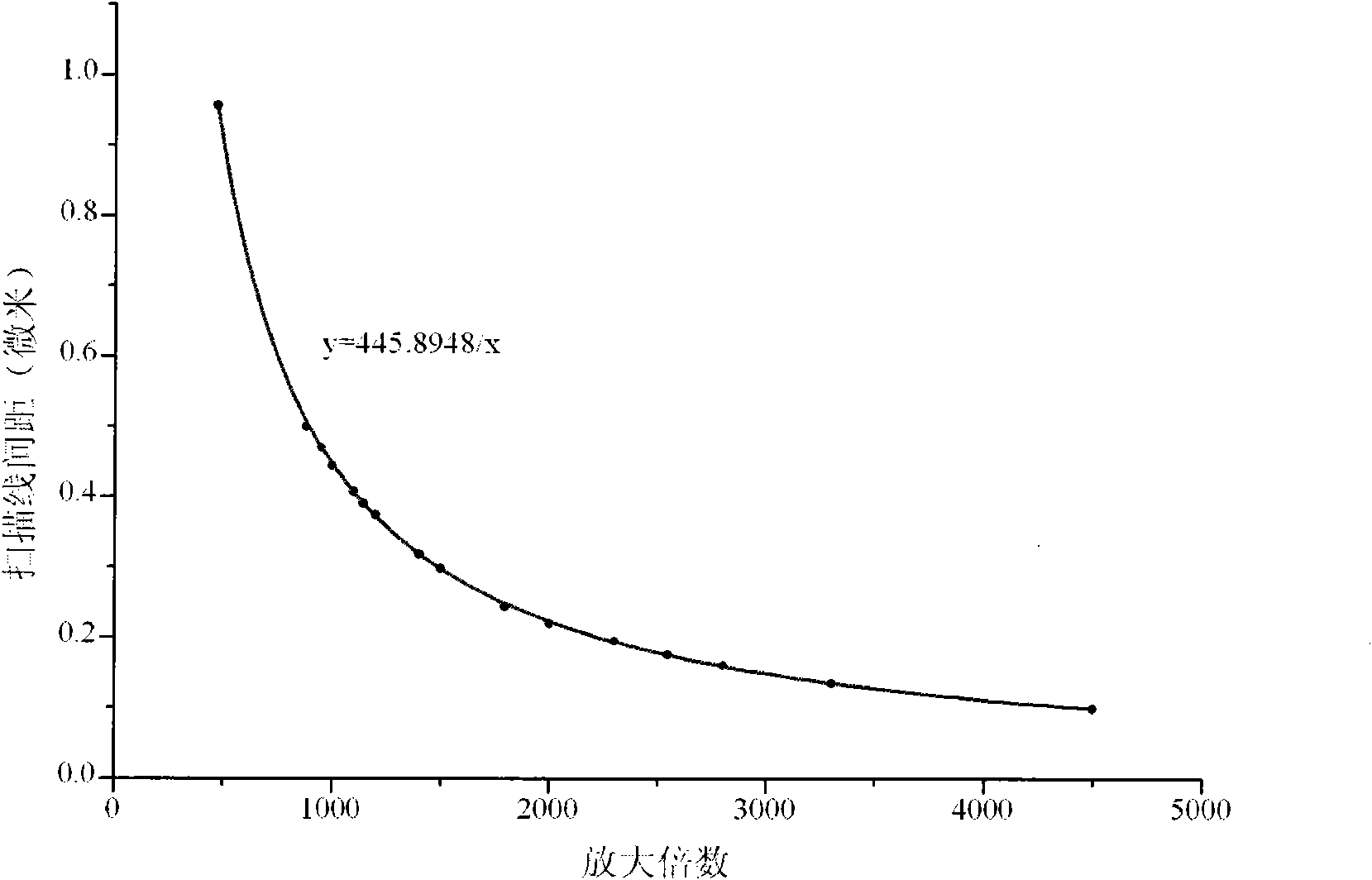

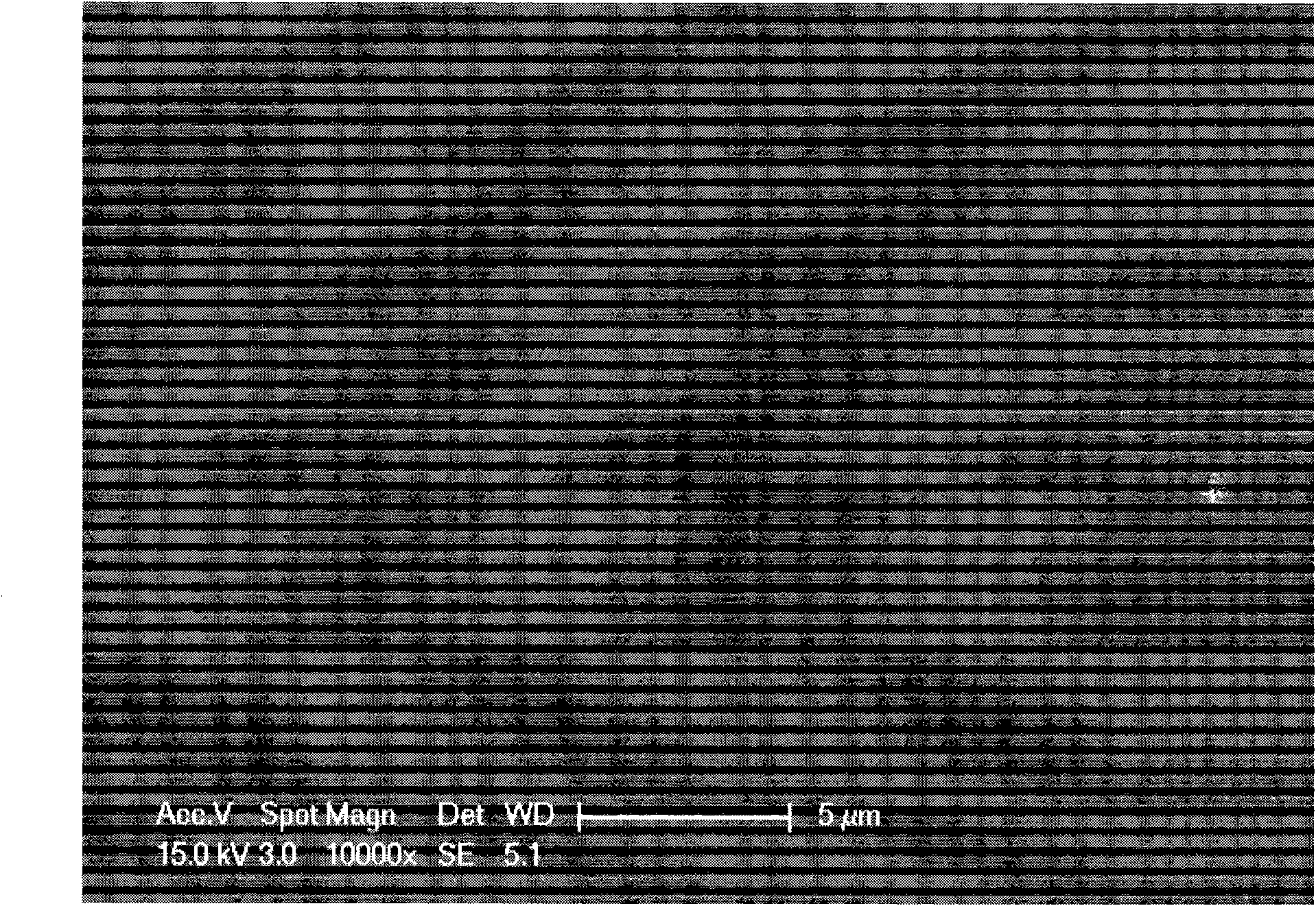

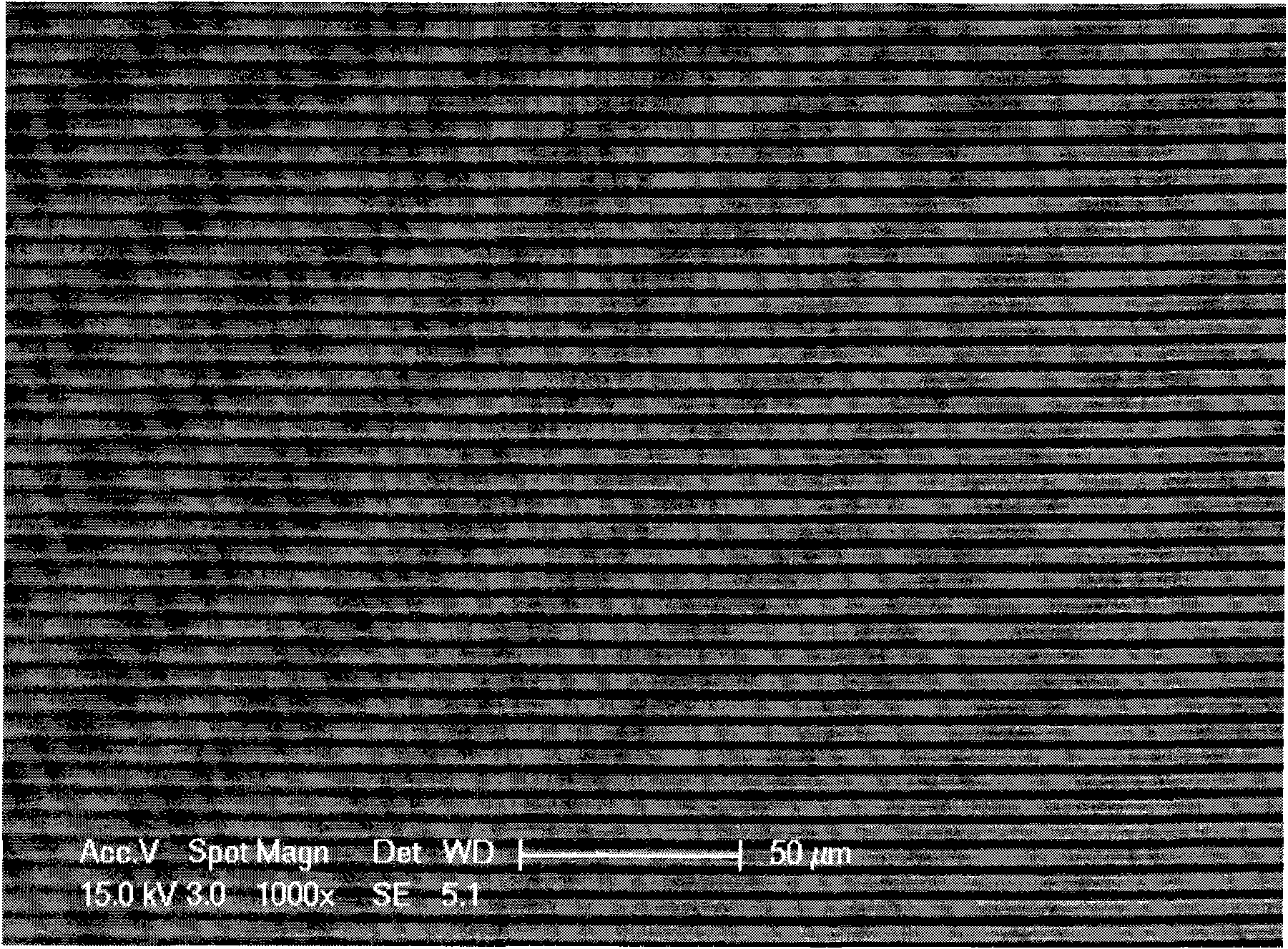

[0027] The scanning electron microscope model used is FEI Sirion 400NC. Firstly, perform a preliminary calibration of the scanning line spacing of the scanning electron microscope: take a calibration specimen and place it on the scanning electron microscope sample stage, select the number of scanning lines and working distance: 484 lines and 5.1mm, and record the images and images of the specimens at different magnifications Ruler, use image software such as Photoshop to measure the number of pixels corresponding to the image ruler at different magnifications, obtain the calibrated physical size corresponding to each pixel, that is, the scan line spacing, and fit the scan line spacing and the magnification to get the fit Curve and its expression, such as figure 1 Shown. The standard grating used in this experiment is a parallel grating of 2000 lines / mm, then when the scanning line pitch is equal to the standard grating pitch, zero field moiré is formed. According to the fitting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com