Manufacturing method of high-manganese strip steel with high strength and plasticity

A manufacturing method and strip steel technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, metal rolling, etc., can solve the problems that have not been seen in thin slab continuous casting and rolling original strip steel, and achieve broad application prospects and potential , serious element segregation, and excellent thermal processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

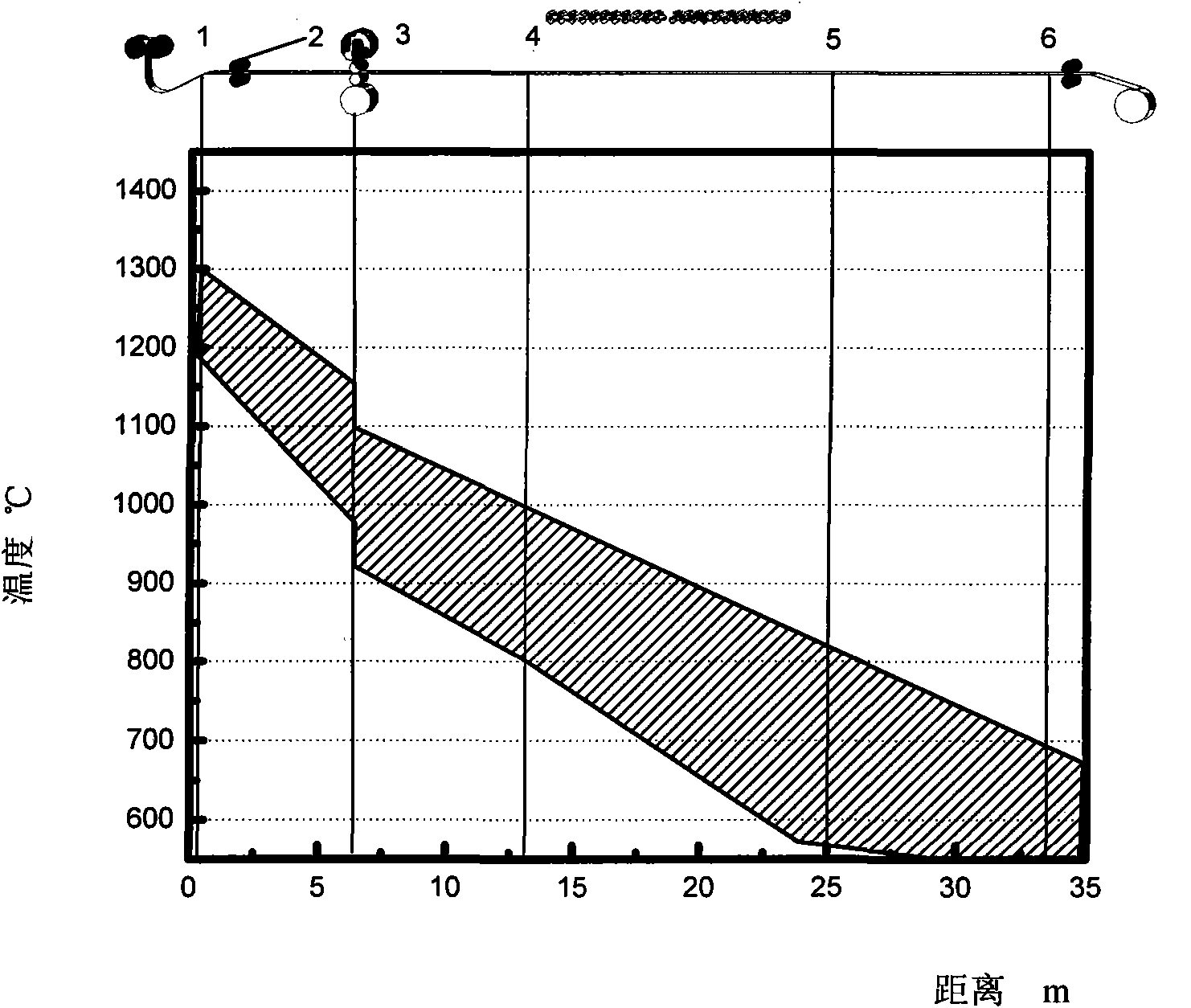

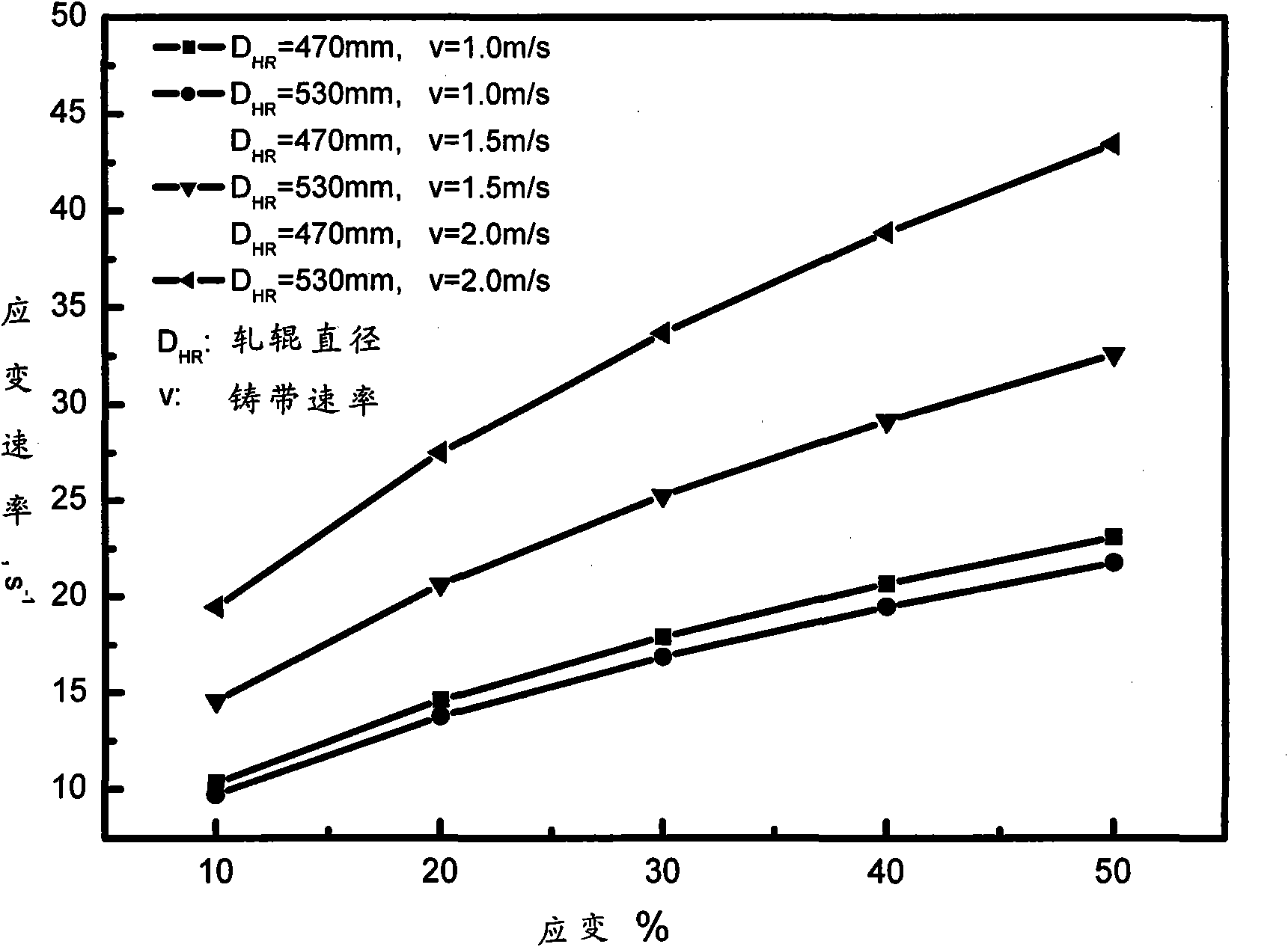

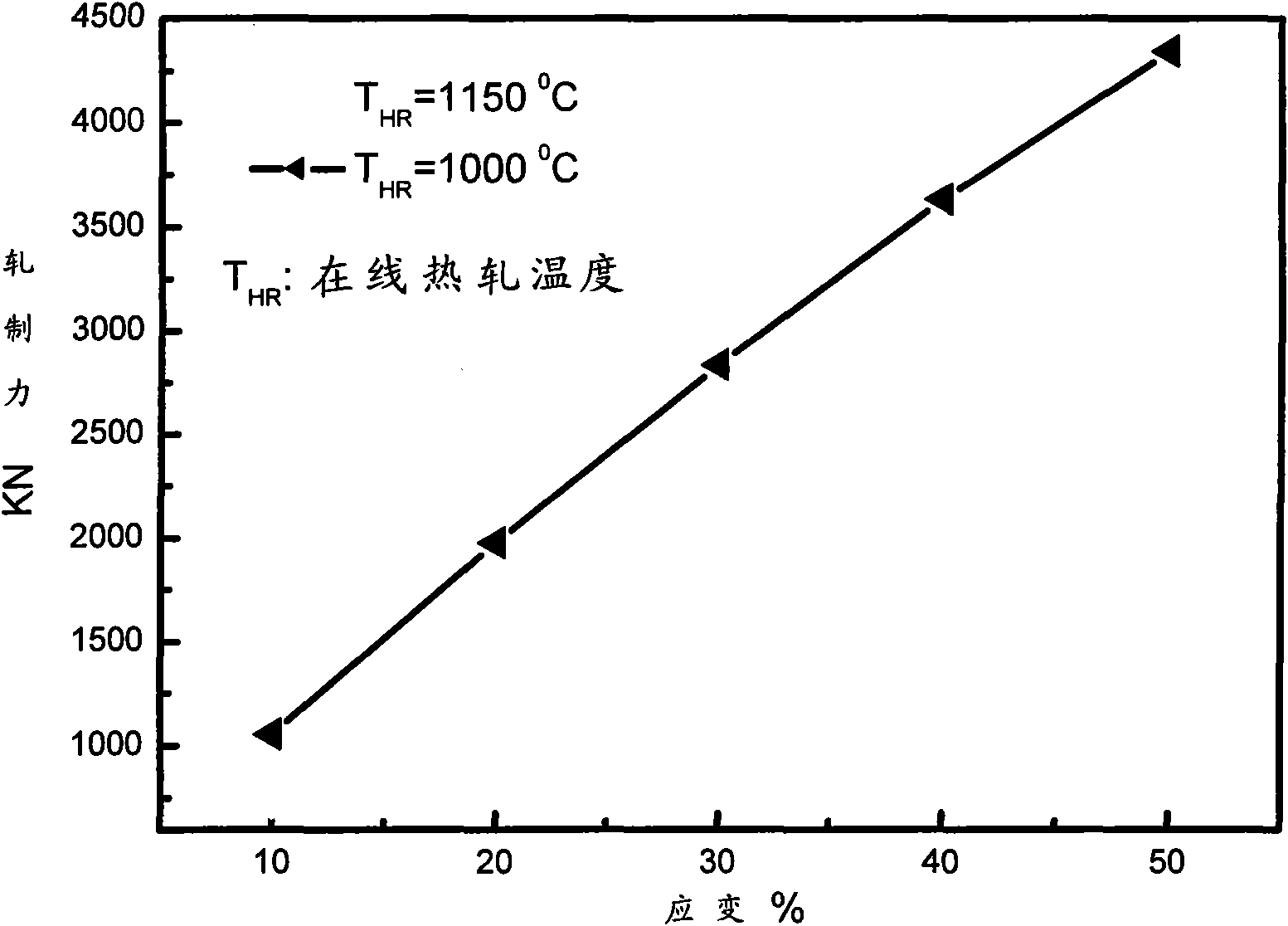

[0079] It is smelted in an electric furnace, and the composition is qualified and placed in an 18-ton ladle. The tapping temperature is 1550°C. The main components of the high-manganese molten steel are as follows (wt%): Mn 23.0%, Si 2.8%, Al 3.0%, C 0.04%, P-1 , The rolling force is about 2000KN, and it is air-cooled to the target temperature of 700°C for coiling.

[0080] Sampling, solution treatment (water quenching) at 1100°C for ≥1 minute, then pickling, cold rolling, with a reduction of 40%; then solution treatment (water quenching) at 1100°C for ≥2 minutes , then pickling, flattening, slitting according to product requirements, and processing into finished rolls. The mechanical properties of strip steel are as Figure 4 shown.

[0081] Transmission electron microscope analysis shows that the structure of strip steel is a single austenite phase before stretching, and the structure is still austenite after stretching, forming a large number of twins with a distance of te...

Embodiment 2

[0083]Smelted in an electric furnace, the composition is qualified and placed in an 18-ton ladle, the tapping temperature is 1570°C, and the main components of the high manganese molten steel are as follows (wt%): Mn 15.0%, Si 3.5%, Al 3.2%, C 0.03%, P-1 , The rolling force is about 2200KN, and the head is water-cooled to the target temperature of 600°C for coiling.

[0084] Sampling, after solution treatment (water quenching) at 1050°C, pickling, cold rolling, the reduction is 50%, then solution treatment (water quenching) at 1050°C, pickling, smoothing, slitting according to product requirements , processed into finished rolls. The mechanical properties of strip steel are as Figure 4 shown.

[0085] Figure 4 It is the mechanical property index of embodiment 1,2 sample. In the figure, the mechanical performance index of Example 1: tensile strength 640-660Mpa; elongation 50-60%; yield strength 250-280Mpa. After calculation: the strong-plastic product is 32,000-39,600Mpa%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com