Polysulfone oligomer-containing thermosetting epoxy resin adhesive and preparation method thereof

A technology of epoxy resin and oligomer, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., to achieve the effect of excellent bonding strength and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

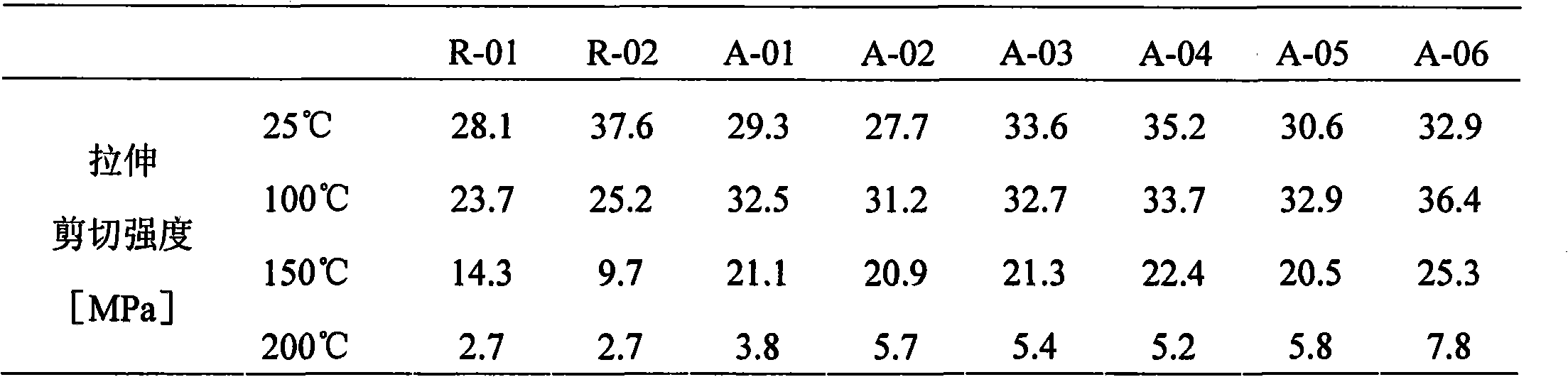

[0010] Embodiment 1: In this embodiment, the heat-cured epoxy resin adhesive containing polysulfone oligomer is diluted with 100 parts of epoxy compound, 5-60 parts of polysulfone oligomer, and 0-15 parts of epoxy agent, 10-50 parts of filler and 6-30 parts of epoxy curing agent.

[0011] In this embodiment, polysulfone oligomers are synthesized from bisphenol compounds and dichlorodiphenyl sulfone.

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the epoxy compound is a composition of one or two of polyurethane modified epoxy resin and bisphenol A epoxy resin; The epoxy value of the phenol A type epoxy resin is 0.44-0.54. Others are the same as in the first embodiment.

[0013] In this embodiment, when the epoxy compound is a combination of polyurethane modified epoxy resin and bisphenol A epoxy resin, the ratio between the two components is arbitrary.

specific Embodiment approach 3

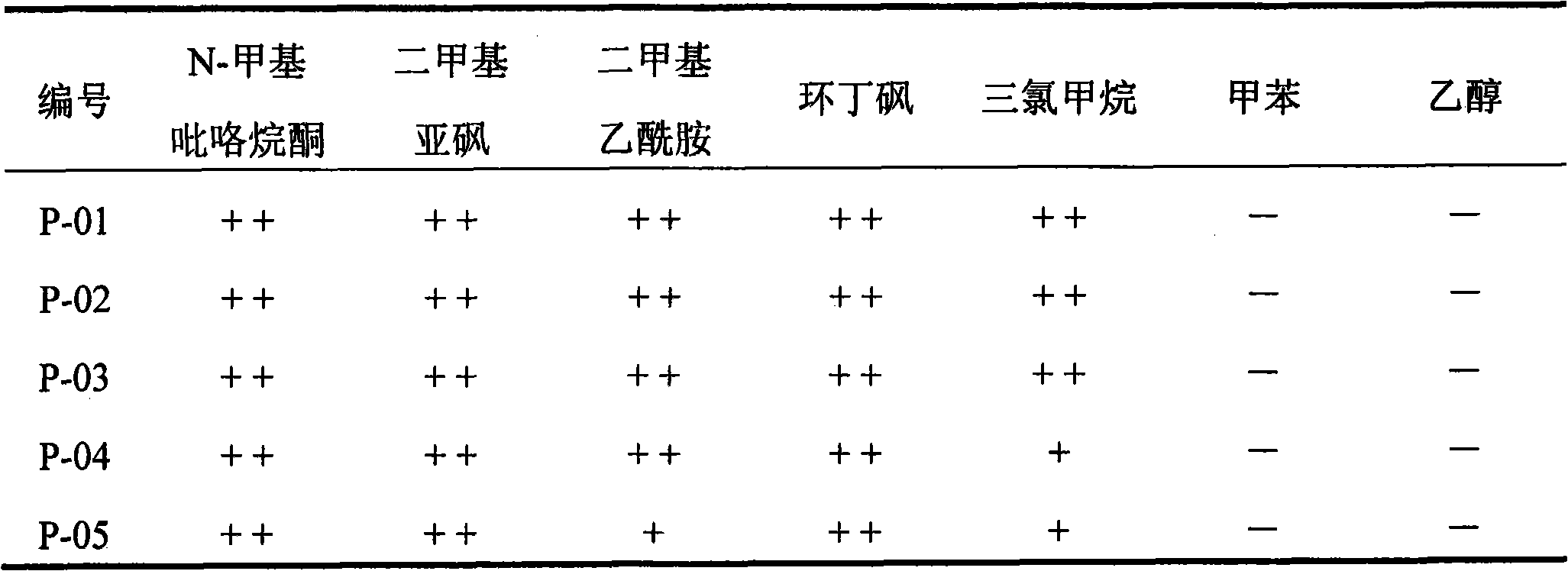

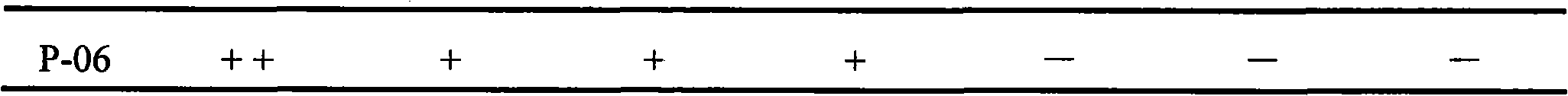

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the polysulfone oligomer is polysulfone oligomer P-01, polysulfone oligomer P-02, polysulfone oligomer P-03, polysulfone oligomer P-04, polysulfone oligomer P-05 or polysulfone oligomer P-06. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com